Beneficiation process for flotation of associated fluorite in floating tungsten tailings

A technology of tungsten tailings and fluorite, which is applied in the field of beneficiation of the recovery of associated fluorite from floating tungsten tailings, can solve the problems of high product impurity content, difficulty in effective separation and extraction of fluorite, and large dosage of chemicals, and achieves high efficiency and selectivity. separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

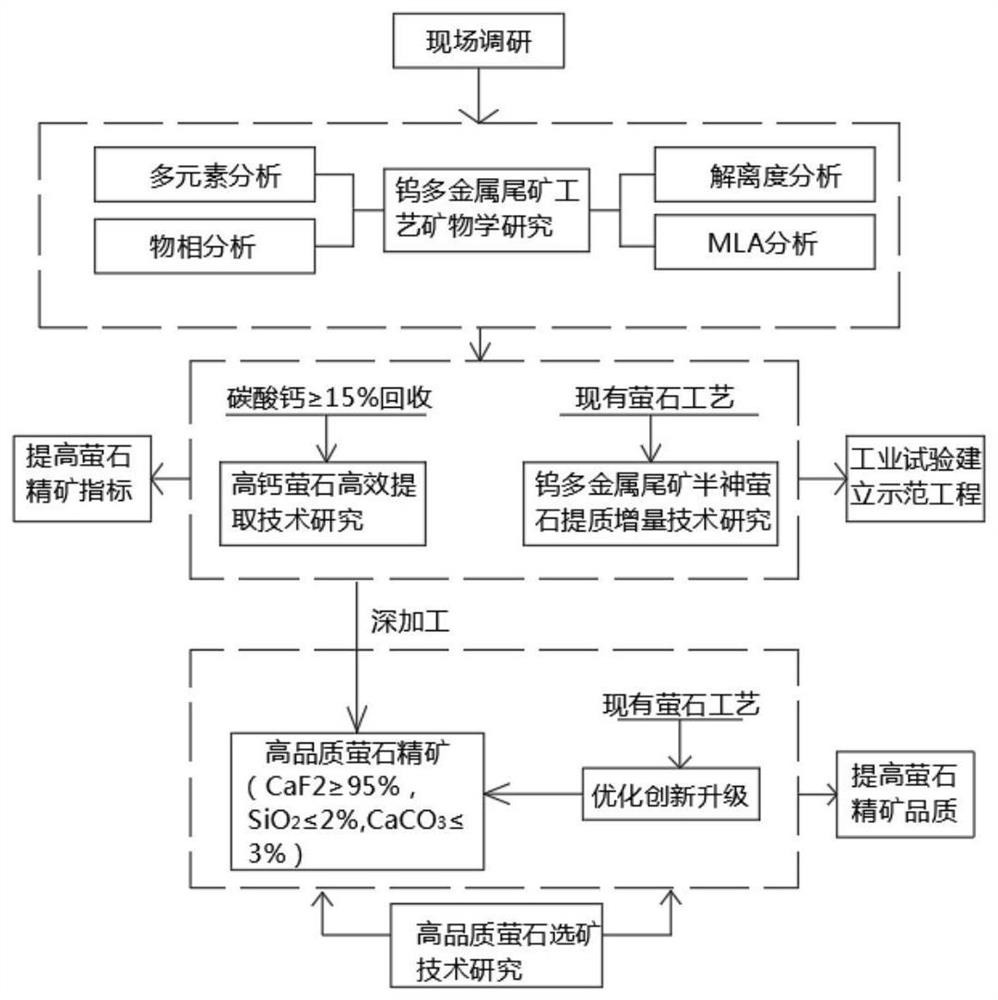

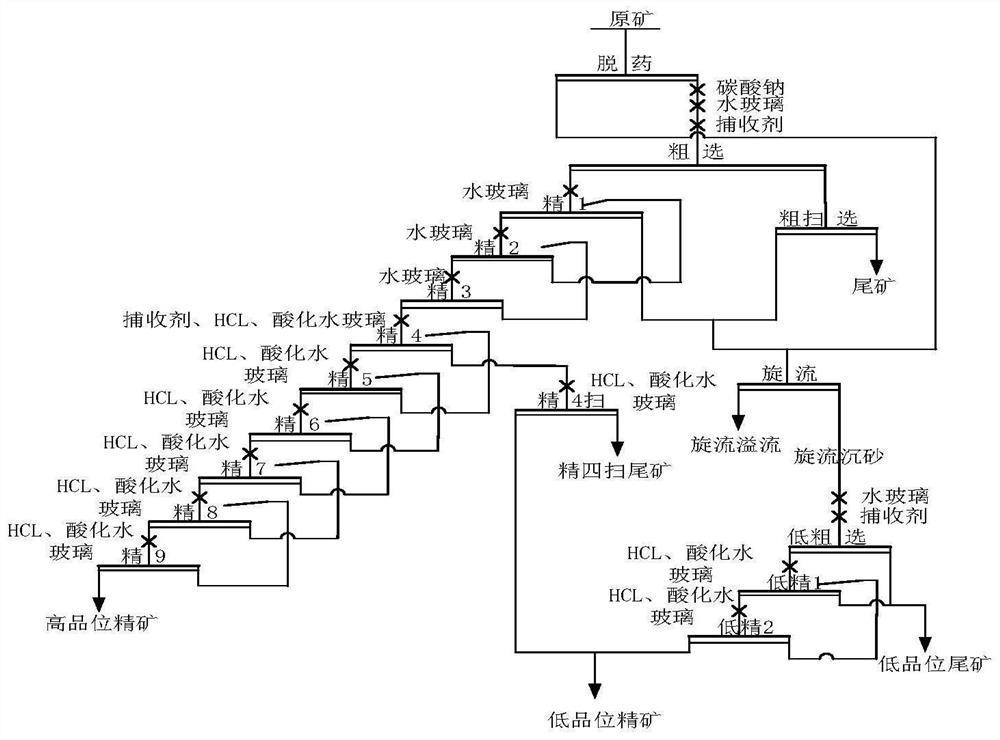

[0042] The invention provides a beneficiation process for flotation of associated fluorite in floating tungsten tailings, which has the advantages of realizing efficient and selective separation of fluorite and carbonate, realizing efficient activation of fluorite, and improving the recovery rate of fluorite concentrate. Please refer to Figure 1-2 , including the following steps:

[0043] S1: Through on-site investigation, the problems existing in the associated fluorite ore in the floating tungsten tailings were found;

[0044] S2: Conduct research on process mineralogy of tungsten polymetallic tailings through multi-element analysis, phase analysis, dissociation analysis and MLA analysis;

[0045] S3: The basis provided by the minera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com