Polyacid complex, nanocomposite material containing same, and application of nanocomposite material in dye adsorption

A technology of nanocomposites and complexes, which is applied in the fields of adsorption water/sewage treatment, water pollutants, other chemical processes, etc., can solve the problems of difficulty in the separation of polyacid compounds, and the large-scale application of compounds that are restricted by recycling. Effectiveness of Utilization, Efficient and Selective Separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a nanocomposite material containing polyacid complexes, specifically comprising the steps of:

[0032] 1) Preparation of Fe 3 o 4 Nanoparticles can be synthesized with reference to literature methods (Liu HongLing., Wu JunHua., MinJi Hyun, Zhang XiaoYan, Kim Young Keun. Tunable synthesis and multifunctionalities of Fe 3 o 4 -ZnO hybrid core-shell nanocrystals. Mater. Res. Bull. 2013, 48 , 551–558).

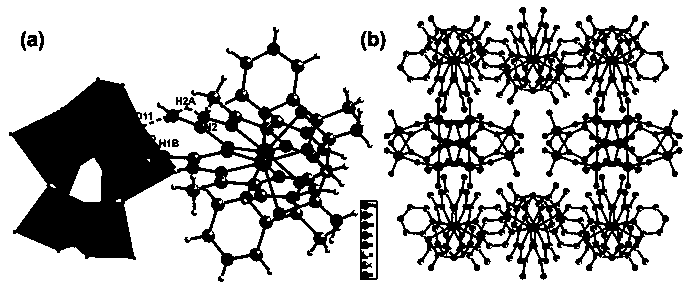

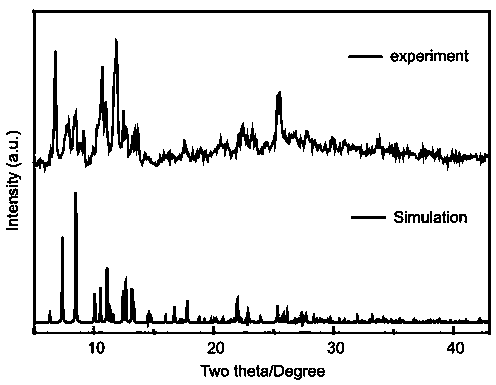

[0033] 2) Preparation of polyacid complexes:

[0034] 2-Acetylpyrazine thiosemicarbazone (0.097 g, 0.5 mmol), Ni(ClO 4 ) 2 ·6H 2 O (0.091 g, 0.25 mmol) was added to a small beaker containing a mixed solution of 15 mL distilled water and 10 mL methanol, stirred at 60°C for 30 min to fully dissolve it, then the solution was cooled to room temperature, and molybdic acid was added Sodium solution (0.24 g, by 1 mmolNa 2 MoO 24 4H 2 O dissolved in 10 mL of water), followed by concentrated H 3 PO 4 Adjust the pH value of the solution so tha...

Embodiment 2

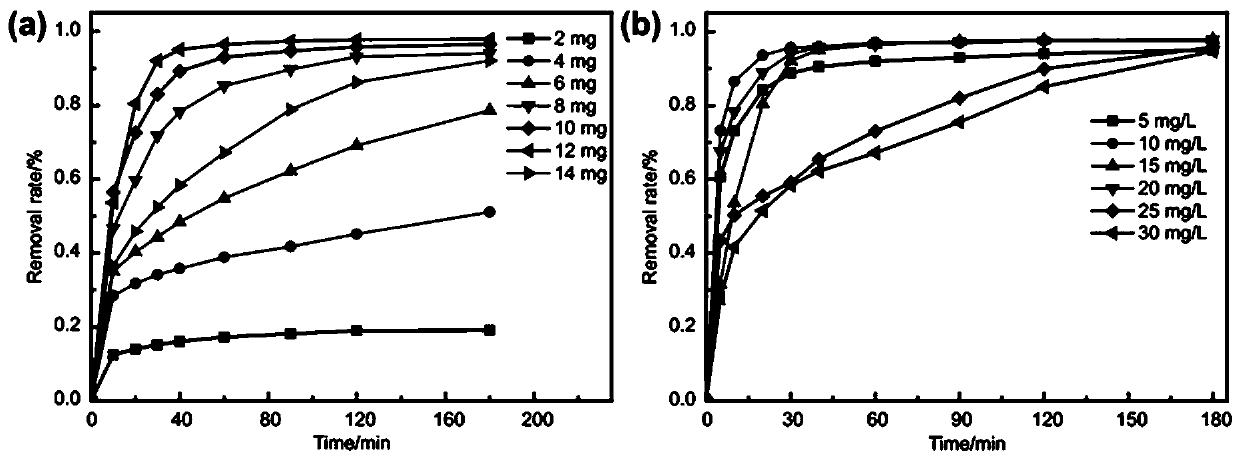

[0041] 2 mg, 4 mg, 6 mg, 8 mg, 10 mg, 12 mg and 14 mg of magnetic adsorbent Fe 3 o 4 The @multi-acid complex was added to 10 mL and 15 mg / L methylene blue solutions respectively, and reacted at room temperature for 3 h. The result is as image 3 As shown in a, when 12 mg of magnetic adsorbent is used, the adsorption efficiency of methylene blue is the highest, which can reach 97.84%. Therefore, for this adsorption process, 12 mg / 10 mL was considered to be the optimal dosage / volume ratio, and this ratio was also used as the implementation of the next investigation.

Embodiment 3

[0043] 12 mg of magnetic adsorbent Fe 3 o 4 Add the polyacid complex to 10 mL methylene blue solution containing 5 mg / L, 10 mg / L, 15 mg / L, 20 mg / L, 25 mg / L and 30 mg / L, and react at room temperature for 3 h . The result is as image 3 As shown in b, as the concentration of methylene blue increases, the adsorption rates of the magnetic adsorbent to methylene blue are 95.02%, 97.53%, 97.84%, 97.76%, 95.81% and 94.70% ( image 3 b). Therefore, 15 mg / L is the optimum adsorption concentration for this process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com