A kind of method for recovering and preparing metallic chromium

A technology of metal chromium and metal chromium powder, which is applied in the field of metallurgy, can solve the problems of secondary pollution, large amount of sludge generation, and no recycling, etc., and achieve the effects of high-efficiency separation, accelerated reduction rate, and accelerated diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

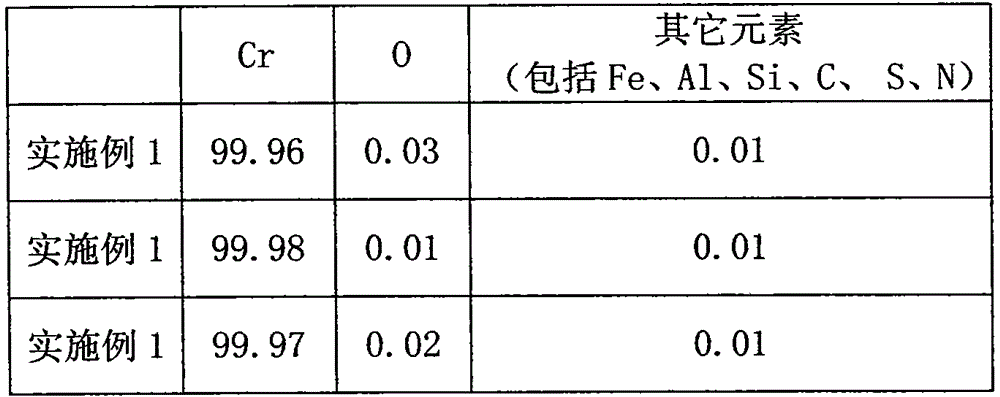

Examples

Embodiment 1

[0027] A method for recovering and preparing metallic chromium, comprising the steps of:

[0028] (1) Add an appropriate amount of sodium sulfate or sodium dihydrogen phosphate to the chromium-containing solution to be treated, adjust the pH of the solution to 2, heat and stir at 50°C for 6 hours, and reduce the chromium (VI) in the chromium-containing solution to Chromium (III);

[0029] (2) Add an organic solvent to the solution treated in step (1), mix thoroughly, and leave to stand or centrifuge to separate phases to obtain a liquid-liquid phase system, the upper layer is an organic solvent phase, and all chromium (III) is transferred to the organic solvent phase middle;

[0030] (3) using an acid solution with a pH lower than 2.0 to recover the chromium (III) supported by the organic solvent;

[0031] (4) adjust the pH of the chromium solution that (3) step stripping reclaims gained is adjusted to 8.6, and chromium is precipitated with hydrate Cr(OH) nH 2 Precipitate i...

Embodiment 2

[0040] A method for recovering and preparing metallic chromium, comprising the steps of:

[0041] (1) Add an appropriate amount of sodium sulfate or sodium dihydrogen phosphate to the chromium-containing solution to be treated, adjust the pH of the solution to 4, heat and stir at 40°C for 7 hours, and reduce the chromium (VI) in the chromium-containing solution to Chromium (III);

[0042] (2) Add an organic solvent to the solution treated in step (1), mix thoroughly, and leave to stand or centrifuge to separate phases to obtain a liquid-liquid phase system, the upper layer is an organic solvent phase, and all chromium (III) is transferred to the organic solvent phase middle;

[0043] (3) using an acid solution with a pH lower than 2.0 to recover the chromium (III) supported by the organic solvent;

[0044] (4) adjust the pH of the chromium solution that (3) step back extraction reclaims gained is adjusted to 8.3, and chromium is precipitated with hydrate Cr(OH) nH 2 Precipi...

Embodiment 3

[0053] A method for recovering and preparing metallic chromium, comprising the steps of:

[0054] (1) Add an appropriate amount of sodium sulfate or sodium dihydrogen phosphate to the chromium-containing solution to be treated, adjust the pH of the solution to 3, heat and stir at 45°C for 6.5h, and reduce the chromium (VI) in the chromium-containing solution is chromium(III);

[0055] (2) Add an organic solvent to the solution treated in step (1), mix thoroughly, and leave to stand or centrifuge to separate phases to obtain a liquid-liquid phase system, the upper layer is an organic solvent phase, and all chromium (III) is transferred to the organic solvent phase middle;

[0056] (3) using an acid solution with a pH lower than 2.0 to recover the chromium (III) supported by the organic solvent;

[0057] (4) adjust the pH of the chromium solution that (3) step stripping reclaims gained is adjusted to 8.5, and chromium is precipitated with hydrate Cr(OH) nH 2 Precipitate in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com