Preparation method for quickly quenched Fe-based metal grain with excellent wave absorbing property

A technology of base metal and magnetic metal, which is applied in the field of preparation of rapidly quenched Fe-based metal particle materials, can solve the problem of non-reflection absorption, etc., and achieve the effect of high practical value, correct principle and scientific means.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

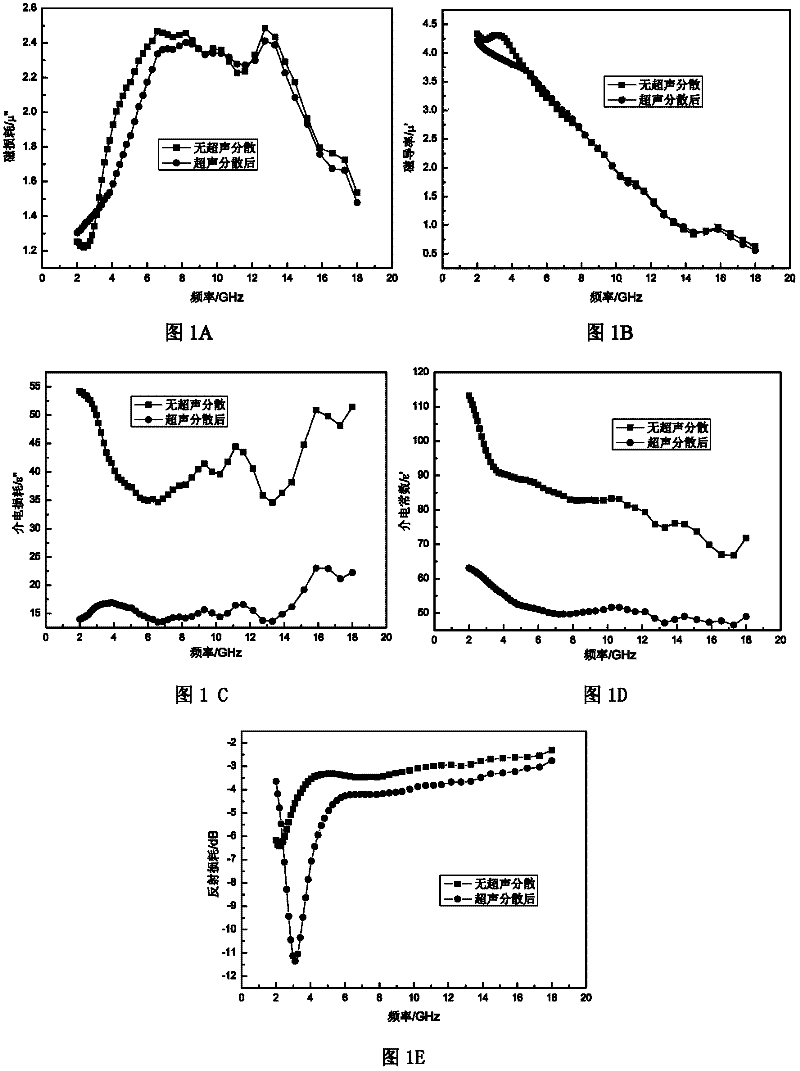

Image

Examples

Embodiment 1

[0023] (1) The proportion of high-purity iron rod (99.9wt%) is 65-70%, the proportion of neodymium block (99.9wt%) is 2-4%, the proportion of analytical pure cobalt sheet (99.8wt%) is 16-20%, analytical pure The proportion of boron (99.8wt%) is 9-13%. Weigh the corresponding mass of metal according to the atomic percentage of each element in the alloy, make it into a magnetic metal alloy, and melt it in a high-frequency induction melting furnace to obtain an alloy ingot. , in order to ensure the uniformity of the ingredients, the melting was repeated twice.

[0024] Melting strips are smelted in a vacuum quenching furnace. Put the alloy ingot into the crucible, under the state of vacuuming and filling with argon, the alloy ingot is melted by the high-voltage arc of the tungsten-cerium electrode, and the molten solution is thrown into a thin strip by the high-speed rotating molybdenum wheel. Then the obtained ribbons were roughly crushed with a pulverizer, then finely ground w...

Embodiment 2

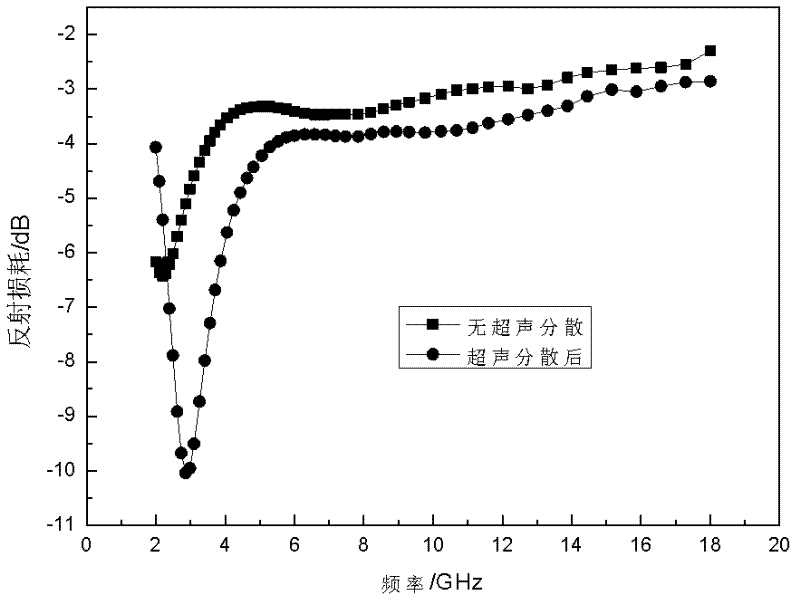

[0035] The method for preparing the Nd-Fe-Co-based magnetic metal particle material in Example 1 is the same, but the ultrasonic frequency is set to 3.0 GHz, and the ultrasonic time is 30 min. The prepared Nd-Fe-Co-based magnetic metal particles and the untreated Nd-Fe-Co-based magnetic metal particles (film thickness 1.5mm) were calculated and compared according to the line transmission theory through reflection loss (see figure 2 ) Obtained the conclusion consistent with embodiment 1.

Embodiment 3

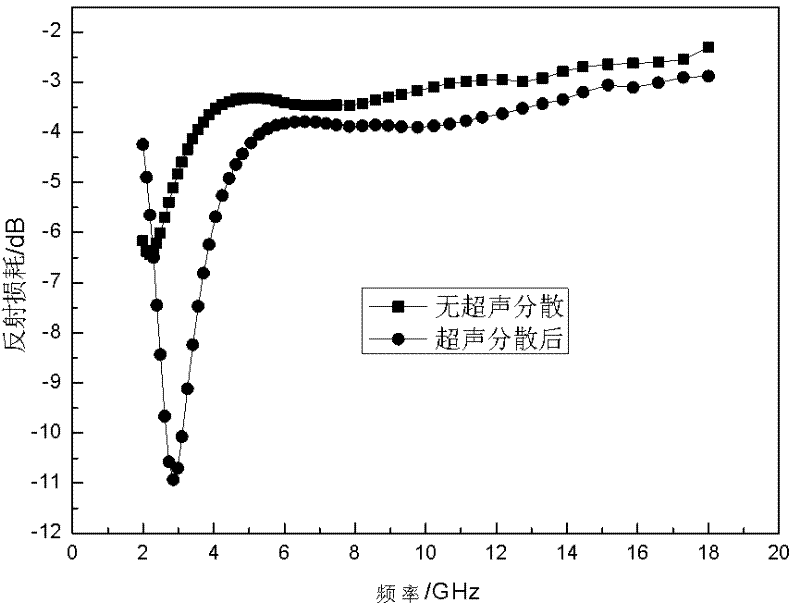

[0037] The method for preparing the Nd-Fe-Co-based magnetic metal particle material is the same as that in Example 1, but the ultrasonic frequency is set to 3.5 GHz, and the ultrasonic time is 40 min. The prepared Nd-Fe-Co-based magnetic metal particles and the untreated Nd-Fe-Co-based magnetic metal particles (film thickness 1.5mm) were calculated and compared according to the line transmission theory through reflection loss (see image 3 ) Obtained the conclusion consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Maximum reflection loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com