Wave-absorbing material as well as preparation method and application thereof

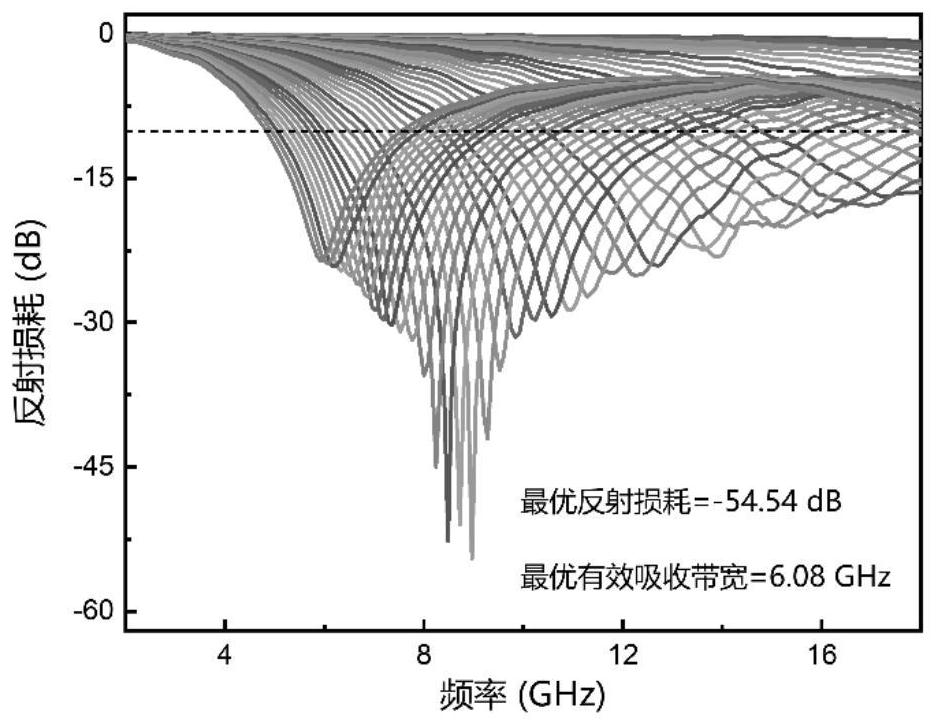

A technology of wave absorbing materials and oxides, applied in the field of wave absorbing materials, can solve the problems of pollution and complex synthesis process, and achieve the effect of simple process, abundant raw material sources, and high-value utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

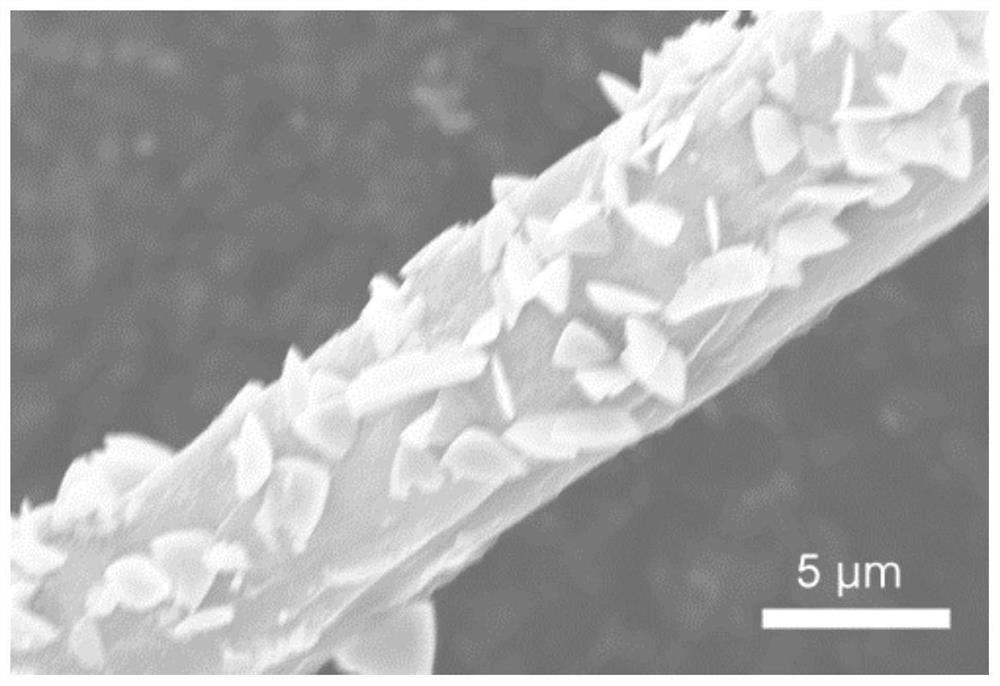

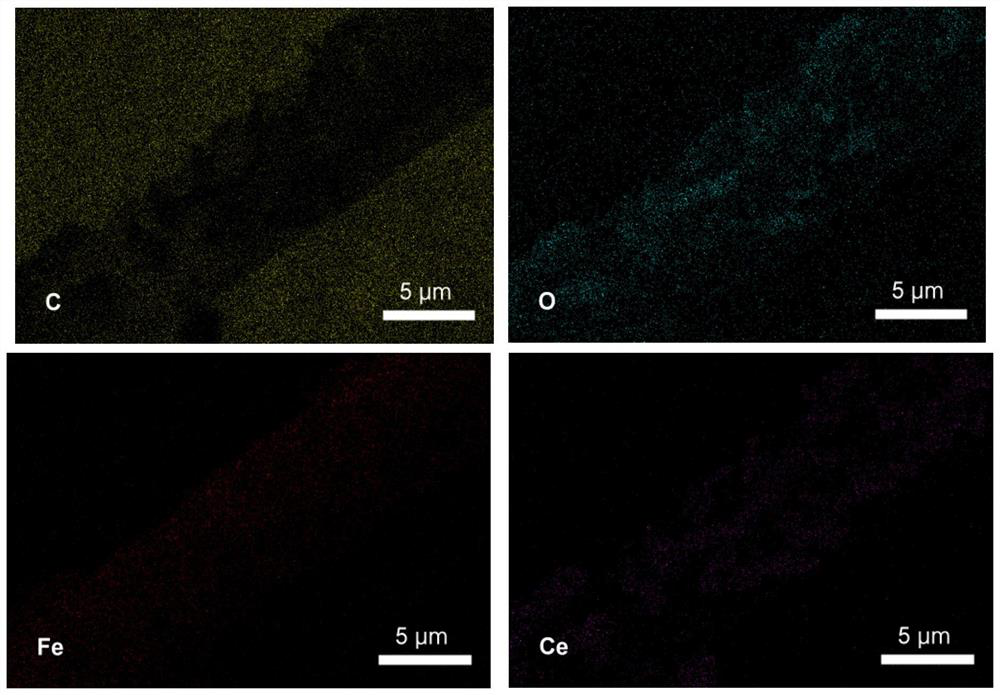

[0048] Step 1: Cut 10.0 grams of kapok fibers into short fibers about 0.1 mm long, add them to 400 mL of sodium chlorite aqueous solution with a concentration of 0.00125 g / mL, stir for 0.5 h at 30 °C and 200 r / min, and filter to obtain The solid substance was added to 400mL of chloroacetic acid aqueous solution with a concentration of 0.0025g / mL, stirred at 30°C and 200r / min for 0.5h, the solid substance was filtered, washed with water until neutral, and dried with air at 50°C to obtain pro- Water-based kapok fiber;

[0049] Step 2, the hydrophilic kapok fiber that step 1 is made, joins in the mixed aqueous solution of 400mL cerium nitrate hexahydrate and ferric nitrate nonahydrate (in the solution, the concentration of cerium nitrate hexahydrate, ferric nitrate nonahydrate is respectively 0.00125g / mL), stirred at 30°C and 200r / min for 0.5h, then adjusted the pH value to 9 with ammonia water, transferred to a 500mL polytetrafluoroethylene-lined autoclave for hydrothermal reac...

Embodiment 2

[0055] Step 1: Cut 10.0 grams of kapok fibers into short fibers about 3 mm long, add them to 400 mL of sodium chlorite aqueous solution with a concentration of 0.0075 g / mL, stir for 2 hours at 60 °C and 600 r / min, and filter the obtained Add the solid substance to 400mL of chloroacetic acid aqueous solution with a concentration of 0.00625g / mL, stir at 60°C and 600r / min for 2h, filter the solid substance, wash it with water until neutral, and dry it with air at 80°C to obtain a hydrophilic kapok fiber;

[0056] Step 2, the hydrophilic kapok fiber that step 1 makes is joined in the mixed aqueous solution of 400mL cerium nitrate hexahydrate and ferric nitrate nonahydrate (the concentration of cerium nitrate hexahydrate in the solution is 0.015775g / mL, ferric nitrate nonahydrate The concentration is 0.0109g / mL), stirred at 60°C and 600r / min for 2h, then adjusted the pH value to 10 with ammonia water, transferred to a 500mL polytetrafluoroethylene-lined autoclave for hydrothermal r...

Embodiment 3

[0062] Step 1: Cut 10.0 grams of kapok fibers into short fibers about 10 mm long, add them to 400 mL of sodium chlorite aqueous solution with a concentration of 0.125 g / mL, stir at 90 °C and 1200 r / min for 12 hours, and filter the obtained Add the solid substance to 400mL of chloroacetic acid aqueous solution with a concentration of 0.25g / mL, stir at 90°C and 1200r / min for 12h, filter the solid substance, wash it with water until neutral, and dry it with air at 120°C to obtain a hydrophilic kapok fiber;

[0063] Step 2, the hydrophilic kapok fiber that step 1 is made, joins in the mixed aqueous solution of 400mL cerium nitrate hexahydrate and ferric nitrate nonahydrate (in the solution, the concentration of cerium nitrate hexahydrate, ferric nitrate nonahydrate is respectively 0.375g / mL), stirred at 90°C and 1200r / min for 12h, then adjusted the pH value to 12 with ammonia water, transferred to a 500mL polytetrafluoroethylene-lined autoclave for hydrothermal reaction at 240°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com