Sulfur and nitrogen double-doped graphene wave-absorbing material, production method and wave-absorbing performance adjusting method

A wave-absorbing material and double-doping technology, applied in the fields of graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of inability to achieve full-band adjustable absorption, low wave absorption performance, and difficult film forming of products. , to achieve the effect of facilitating industrialized large-scale production, excellent wave absorption properties, and excellent wave absorption properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, the preparation of sulfur and nitrogen double-doped graphene and the control scheme of absorbing properties are carried out as follows:

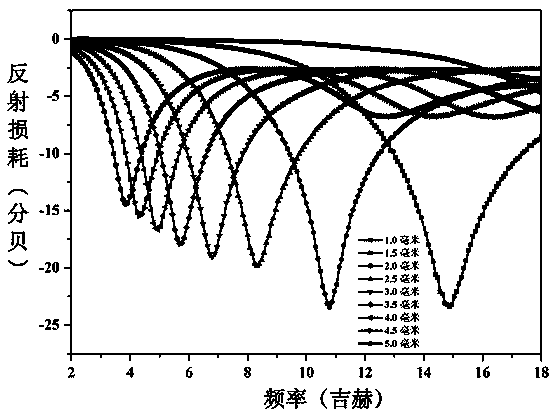

[0037] Preparation of sulfur-nitrogen double-doped graphene wave-absorbing material: Take 5-10mmol of reducing agent containing sulfur and nitrogen elements, add 10-300mL of 1-2mg / mL graphite oxide solution, heat to 80-100 o C. Continue the constant heat reaction for 1-3h. After the reaction is over, cool to room temperature, wash and filter with a large amount of deionized water 6-10 times, freeze-dry for 24-48h, and obtain black sulfur-doped graphene powder with a conductivity of 1.86 Scm -1 . Composite with 30-70% paraffin, when the thickness is 2.0mm, it absorbs at 10.85GHz, and the lowest reflection loss is -23.4dB; when the thickness is 1.5mm, it absorbs at 14.90GHz, and the lowest reflection loss is -23.3dB; see figure 1 .

Embodiment 2

[0039] In this embodiment, the preparation of sulfur and nitrogen double-doped graphene and the control scheme of absorbing properties are carried out as follows:

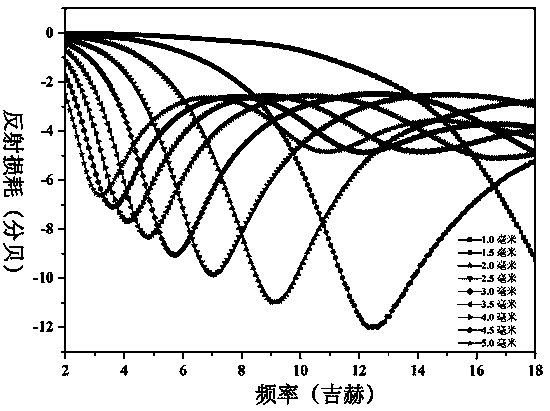

[0040] Preparation of sulfur-nitrogen double-doped graphene wave-absorbing material: Take 10-20mmol of reducing agent containing sulfur and nitrogen elements, add 10-300mL of 1-2mg / mL graphite oxide solution, heat to 80-100℃, and keep constant heat React for 1-3 hours. After the reaction is over, cool to room temperature, wash and filter with a large amount of deionized water 6-10 times, and freeze-dry for 24-48 hours to obtain black sulfur-nitrogen double-doped graphene powder with a conductivity of 2.41Scm -1 . Composite with 30-70% paraffin, absorb at 12.35GHz when the thickness is 1.5mm, the lowest reflection loss is -12.02dB, see figure 2 .

Embodiment 3

[0042] In this embodiment, the preparation of sulfur and nitrogen double-doped graphene and the control scheme of absorbing properties are carried out as follows:

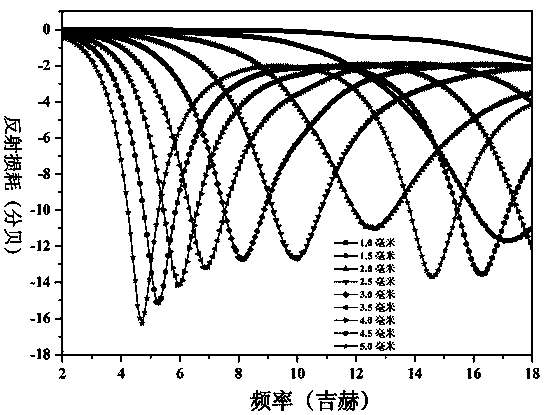

[0043]Preparation of sulfur-nitrogen double-doped graphene wave-absorbing material: Take 20-30mmol of reducing agent containing sulfur and nitrogen elements, add 10-300mL of 1-2mg / mL graphite oxide solution, heat to 80-100°C, and continue to heat React for 1-3h. After the reaction is over, cool to room temperature, wash and filter with a large amount of deionized water 6-10 times, and freeze-dry for 24-48h to obtain black sulfur-doped graphene powder with a conductivity of 3.77Scm -1 . Composite with 30-70% paraffin, absorb at 4.79GHz when the thickness is 5.0mm, the lowest reflection loss is -16.3dB, see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com