Preparation method of iron-based composite wave-absorbing material

A composite wave-absorbing material, iron-based technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of undisclosed absorption characteristics of wave-absorbing materials, application limitations, etc., to improve wave-absorbing characteristics, improve absorption The effect of wave performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

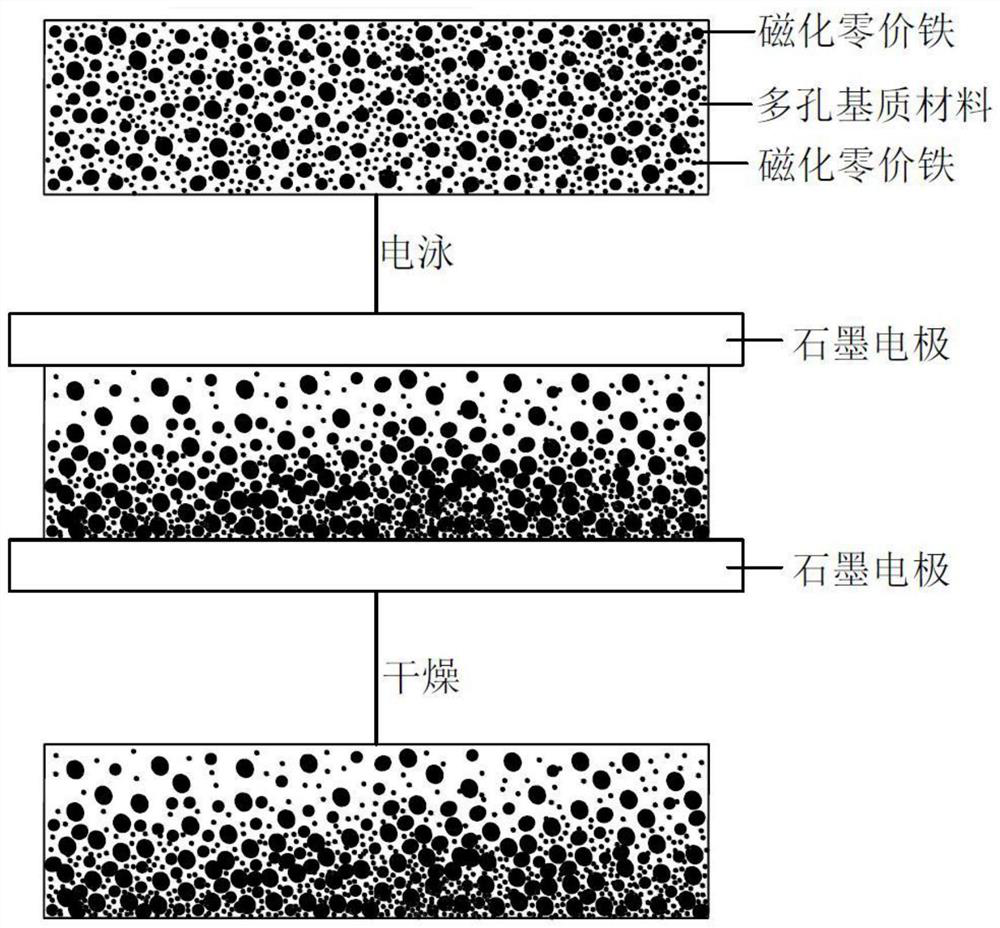

[0079] Example 1: An iron-based composite absorbing material:

[0080] S101: Under stirring at 180r / min, add 10mL of methyltriethoxysilane to 200mL of 70vol% ethanol solution, then add 25mL of 12% hydrochloric acid, continue stirring for 1h, raise the temperature to 45°C and stir for 24h; then add 3mL of 25% ammonia water, after stirring for 30min, add 0.45g of iron porphyrin, then stir for 30min, let it stand for 1h, and place it at a constant temperature of 45°C to form a gel; after the gel is formed, add 3mL of ethanol / ethyl orthosilicate mixture (volume Ratio 1:4), aging at room temperature for 24 hours, drying at 50°C to constant weight to obtain a porous matrix material doped with iron porphyrin, material thickness 2mm;

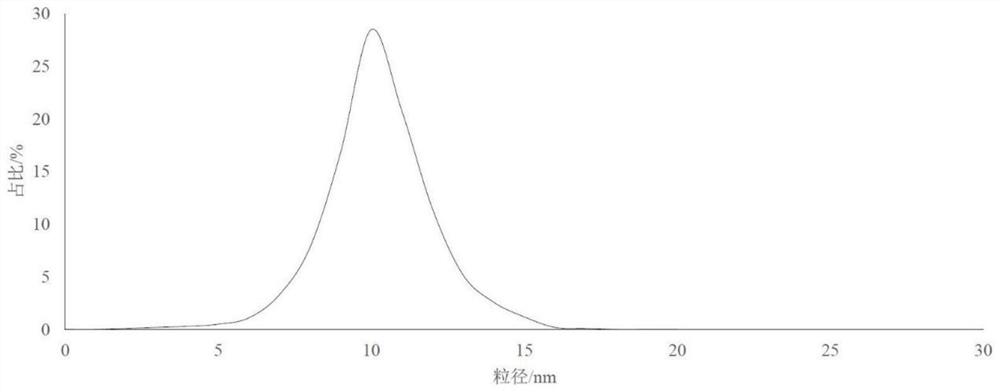

[0081] S102: Dissolve 10g of urea and 3g of zinc acetate in 200mL of ultrapure water, then add 30g of ethylenediamine, stir at 300r / min at room temperature, heat at 185°C for 8h, and cool down to room temperature naturally to obtain a brown solution, fi...

Embodiment 2

[0085] Example 2: Another iron-based composite absorbing material:

[0086] S101: Stirring at 180r / min, add 10mL of methyltriethoxysilane to 300mL of 70vol% ethanol solution, then add 20mL of 15% hydrochloric acid, continue stirring for 1h, raise the temperature to 45°C and stir for 24h; then add 5mL of 22% ammonia water, after stirring for 30min, add 0.6g of iron porphyrin, then stir for 30min, let it stand for 1h, and place it at a constant temperature of 45°C to form a gel; after the gel is formed, add 3mL of ethanol / ethyl orthosilicate mixture (volume Ratio 1:4), aging at room temperature for 24 hours, drying to constant weight at 50°C to obtain a porous matrix material doped with iron porphyrin, with a thickness of 2mm;

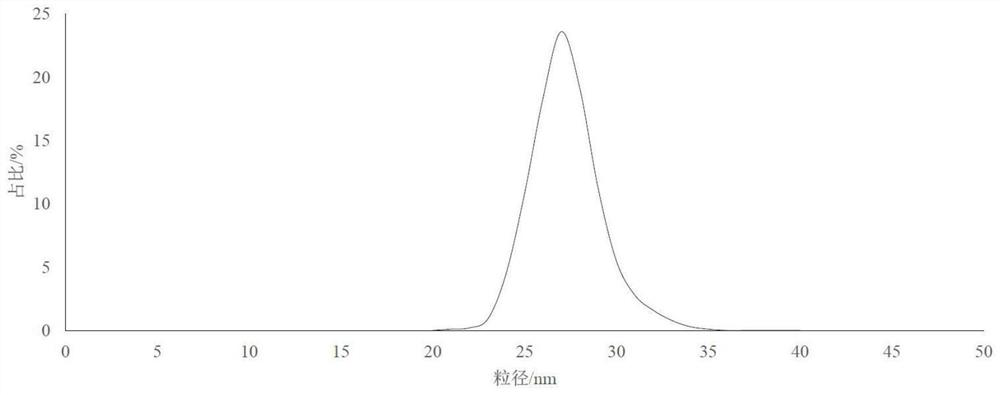

[0087] S102: Dissolve 10g of urea and 2.5g of zinc acetate in 200mL of ultrapure water, then add 25g of ethylenediamine, stir at 300r / min at room temperature, heat at 185°C for 8h, and naturally cool to room temperature to obtain a brown solution with a ...

Embodiment 3

[0091] Example 3: Another iron-based composite absorbing material:

[0092] S101: Under stirring at 300r / min, add 10mL of methyltriethoxysilane to 300mL of 70vol% ethanol solution, then add 25mL of 20% hydrochloric acid, continue stirring for 1h, raise the temperature to 50°C and stir for 24h; then add 4mL of 20% ammonia water, after stirring for 30min, add 0.5g iron porphyrin, then stir for 30min, let it stand for 1h, and place it at a constant temperature of 45°C to form a gel; after the gel is formed, add 4mL ethanol / ethyl orthosilicate mixed solution (volume Ratio 1:4), aging at room temperature for 24 hours, drying at 45°C to constant weight to obtain a porous matrix material doped with iron porphyrin, material thickness 2mm;

[0093] S102: Dissolve 12g of urea and 4g of zinc acetate in 400mL of ultrapure water, then add 35g of ethylenediamine, stir at 600r / min at room temperature, heat at 190°C for 6h, and cool to room temperature naturally to obtain a brown solution, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com