Plasma vacuum coating equipment with function of electrode and workpiece movement and using method

A vacuum coating and plasma technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of poor uniformity and consistency of coating, easy pollution of chemical substances to the environment, and low sedimentation rate. Achieve the effects of improving uniformity and consistency, improving coating production efficiency, and increasing sedimentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

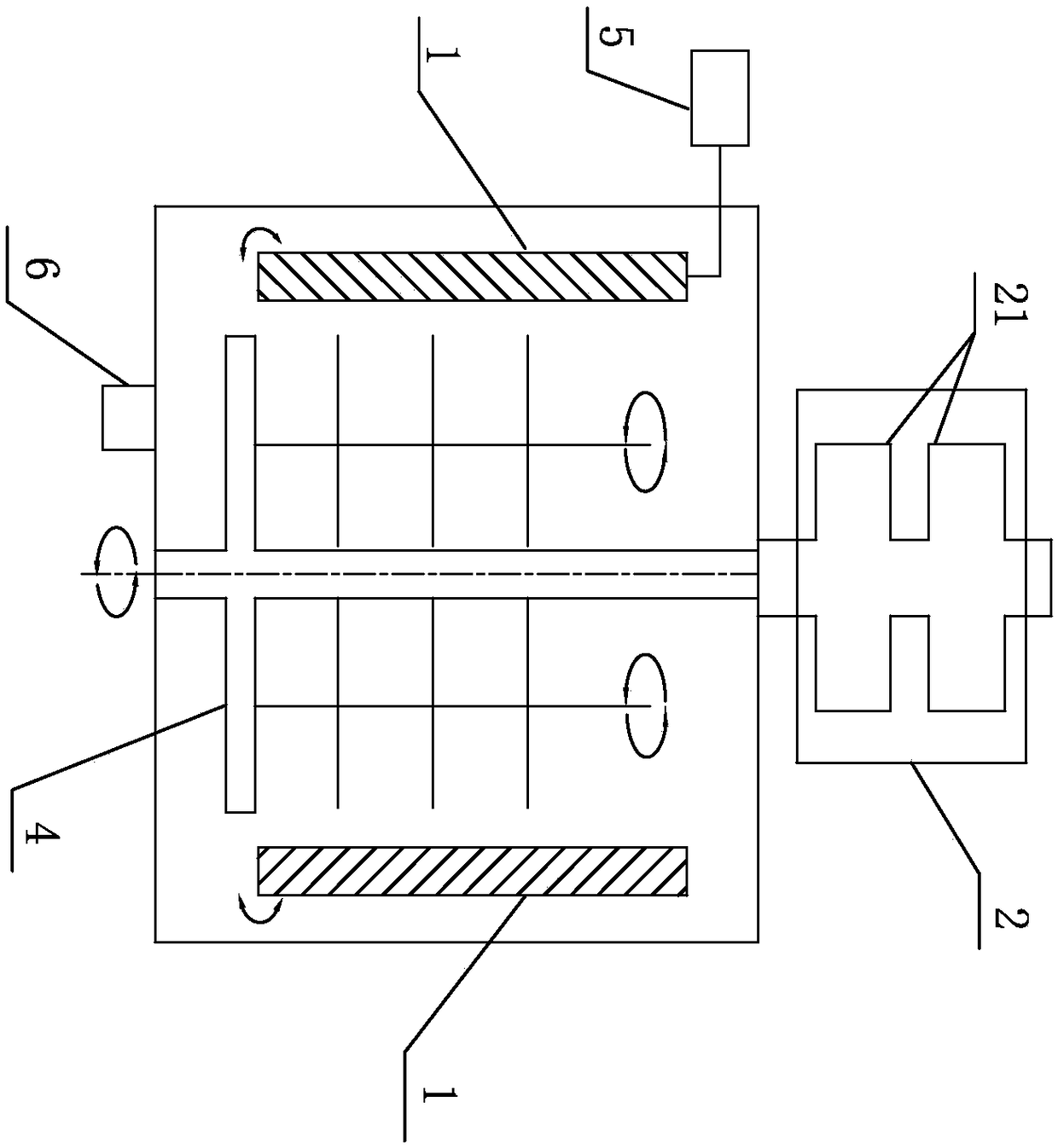

[0029] A plasma vacuum coating equipment with electrodes and workpieces moving, used for coating PCBA, including moving electrodes 1, vacuum exhaust device 2, plasma vacuum chamber 3, moving device 4 for driving workpieces, plasma discharge source 5, air intake The pipeline 6, the plasma discharge source 5 and the vacuum exhaust device 2 are arranged outside the plasma vacuum chamber 3, and the moving electrode 1 and the moving device 4 for driving the workpiece are inside the plasma vacuum chamber 3

[0030] The moving electrodes 1 are arranged inside the cavity 3, and there are one pair in total. The electrodes 1 reciprocate in the cavity 3 along the circumference close to the cavity.

[0031] The vacuum exhaust device 2 includes a vacuum pump 21 and an exhaust pipe. The vacuum pump 21 is divided into one stage and two stages. The vacuum exhaust device 2 is connected to the plasma vacuum chamber 3 through a pipeline.

[0032] The plasma vacuum chamber 3 is a cylindrical cham...

Embodiment 2

[0044] A plasma vacuum coating equipment with electrodes and workpieces moving, used for coating bluetooth earphones, including a moving electrode 1, a vacuum exhaust device 2, a plasma vacuum chamber 3, a moving device 4 that drives the workpiece, a plasma discharge source 5, and a The gas pipeline 6 , the plasma discharge source 5 and the vacuum exhaust device 2 are arranged outside the plasma vacuum chamber 3 , and the moving electrode 1 and the moving device 4 for driving the workpiece are inside the plasma vacuum chamber 3 .

[0045] The moving electrode 1 is arranged inside the vacuum chamber 3 and has two pairs of electrodes, and the electrodes do plane reciprocating motion in the chamber 3 .

[0046] The vacuum exhaust device 2 includes a vacuum pump 21 and an exhaust pipe. The vacuum pump 21 is divided into one stage and two stages. The vacuum exhaust device 2 is connected to the plasma vacuum chamber 3 through a pipeline.

[0047] The plasma vacuum chamber 3 is a cub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com