Preparation method of waterborne acrylic resin with high heat resistance and product obtained by preparation method

A water-based acrylic, heat-resistant technology, applied in coatings, fire-resistant coatings, etc., can solve the problems of poor heat resistance, low hardness, anti-pigment exudation and anti-yellowing, etc., to achieve high heat resistance, good resistance The effect of thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

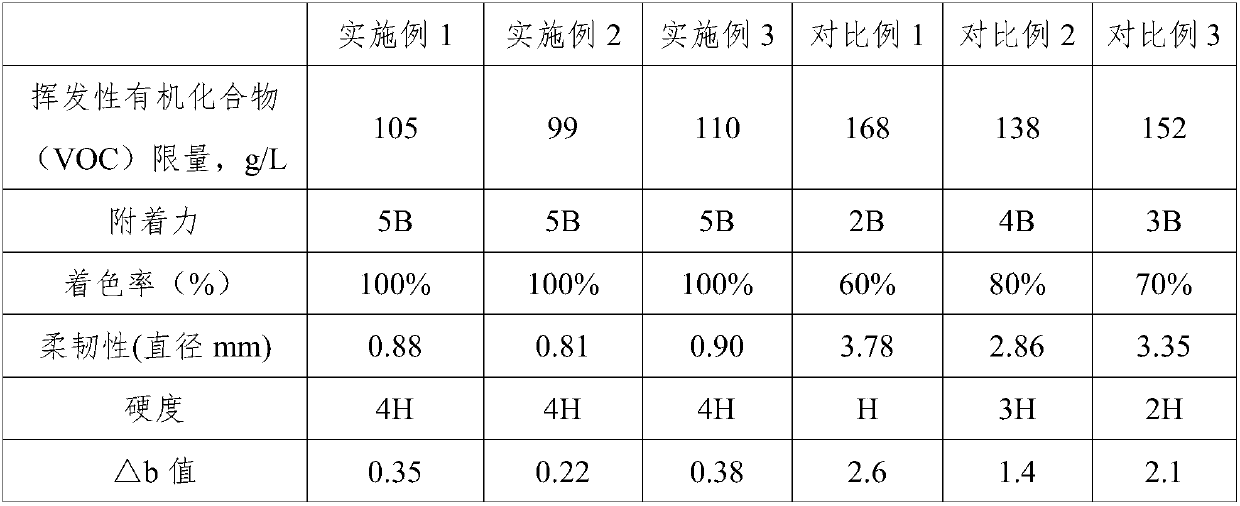

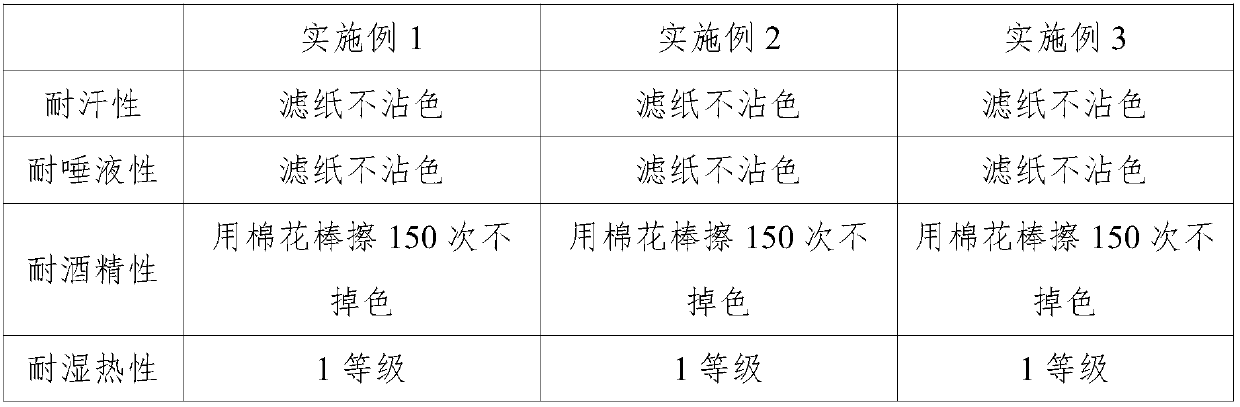

Examples

Embodiment 1

[0031] Embodiment 1, the preparation of a kind of water-based acrylic resin with high heat resistance

[0032] S1 Add 25 parts of dihydrazide carbonate to dimethyl sulfoxide and stir evenly, then add 4 parts of novolak epoxy resin for chain extension modification reaction, react at a temperature of 150°C for 15 minutes, distill under reduced pressure, and remove the solvent , to obtain modified hydrazide;

[0033] S2 Add 160 parts of dipropylene glycol methyl ether, 25 parts of α-methylstyrene, 18 parts of acrylic acid, 8 parts of butyl acrylate and 10 parts of methyl methacrylate into the reaction kettle, blow nitrogen, and stir at 100 rpm. Mix well and heat to 100°C;

[0034] S3 mixes 24 parts of maleic anhydride mixed solution with 3 parts of dicumyl peroxide, and stirs evenly. The maleic anhydride mixed solution is composed of maleic anhydride and styrene in a weight ratio of 1:1 to obtain a mixed solution;

[0035] S4 Add the mixed solution obtained in step S3 dropwise ...

Embodiment 2

[0038] Embodiment 2, the preparation of a kind of water-based acrylic resin with high heat resistance

[0039]S1 Add 28 parts of dihydrazide carbonate to dimethyl sulfoxide and stir evenly, then add 5 parts of novolac epoxy resin for chain extension modification reaction, react at a temperature of 155 °C for 18 minutes, distill under reduced pressure, and remove the solvent , to obtain modified hydrazide;

[0040] S2 Add 170 parts of dipropylene glycol methyl ether, 30 parts of α-methylstyrene, 20 parts of acrylic acid, 12 parts of butyl acrylate and 15 parts of methyl methacrylate into the reaction kettle, blow nitrogen, and stir at 150rpm. Mix well and heat to 120°C;

[0041] S3 mixes 28 parts of maleic anhydride mixed solution with 4 parts of dicumyl peroxide, and stirs evenly. The maleic anhydride mixed solution is composed of maleic anhydride and styrene in a weight ratio of 1:1 to obtain a mixed solution;

[0042] S4 Add the mixed solution obtained in step S3 dropwise ...

Embodiment 3

[0045] Embodiment 3, the preparation of a kind of water-based acrylic resin with high heat resistance

[0046] S1 Add 30 parts of dihydrazide carbonate to dimethyl sulfoxide and stir evenly, then add 5 parts of novolac epoxy resin for chain extension modification reaction, react at a temperature of 160°C for 20 minutes, distill under reduced pressure, and remove the solvent , to obtain modified hydrazide;

[0047] S2 Add 180 parts of dipropylene glycol methyl ether, 35 parts of α-methylstyrene, 25 parts of acrylic acid, 16 parts of butyl acrylate and 20 parts of methyl methacrylate into the reaction kettle, blow nitrogen, and stir at a speed of 200rpm. Mix well and heat to 130°C;

[0048] S3 mixes 30 parts of maleic anhydride mixed solution with 5 parts of dicumyl peroxide, and stirs evenly. The maleic anhydride mixed solution is composed of maleic anhydride and styrene in a weight ratio of 1:1 to obtain a mixed solution;

[0049] S4 Add the mixed solution obtained in step S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com