PS@TiO2 structured color film with non-iridescent effect as well as preparation method and application thereof

A technology of structural color and effect, applied in the direction of coating, etc., can solve the problems of large specific surface area of nano-TiO2, insufficient performance, and many space bonds on the surface, so as to achieve low requirements on the substrate and coating environment, and reduce the iridescent effect , reducing the effect of orderliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

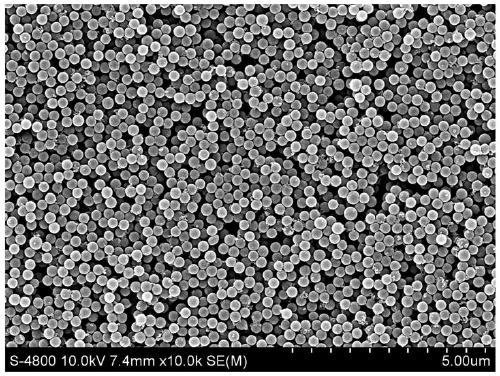

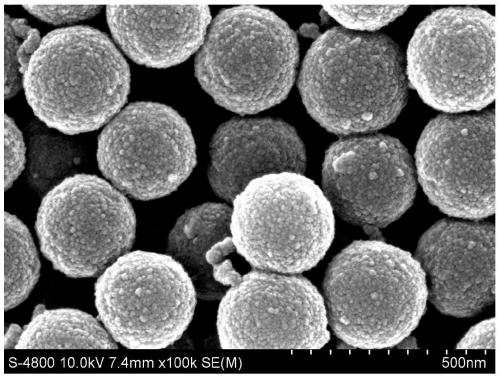

[0034] PS@TiO with non-iridescent effect according to the present invention 2 The preparation method of structural color thin film, comprises the following steps:

[0035]1) Preparation of modified PS colloidal microsphere emulsion: Purification of styrene, adding the purified styrene, α-methacrylic acid and deionized water into a three-neck round bottom flask, magnetically stirring for more than 30min to make the solution evenly mixed, and then Put it in an oil bath at 75-95°C, stir it magnetically for 30-60 minutes, inject potassium persulfate solution, and react under constant temperature to obtain PS microsphere emulsion; the ratio of styrene, α-methacrylic acid and deionized water is: (7-14) mL: (0.5-1) mL: 90 mL.

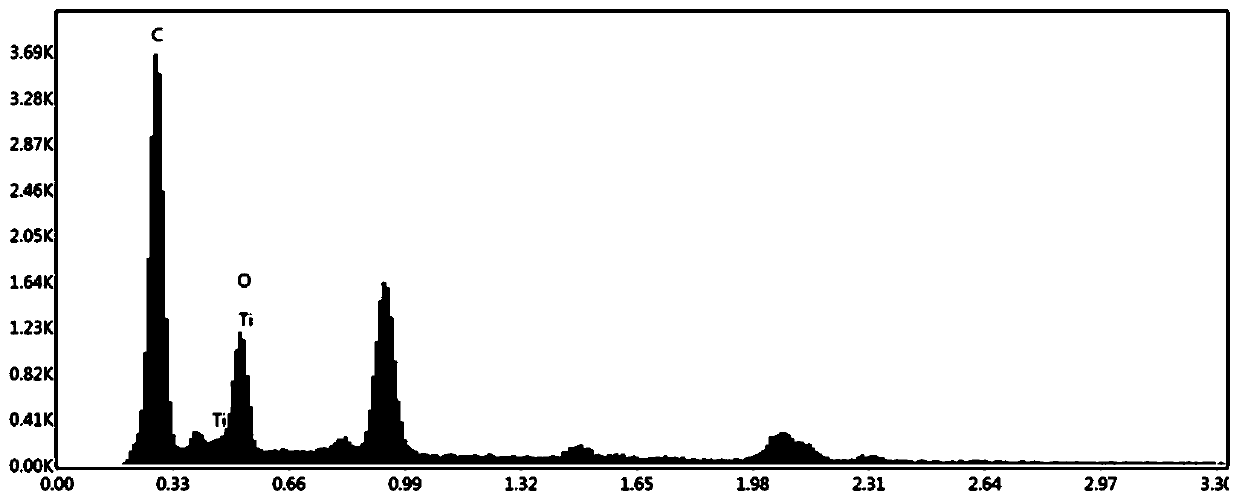

[0036] 2) Encapsulated TiO 2 Shell structure: the obtained PS microsphere emulsion is dispersed in the mixed solution of ethanol and acetonitrile, which is recorded as liquid A; butyl titanate (TBOT) is dissolved in the mixed liquid of ethanol and acetonitri...

Embodiment 1

[0042] A PS@TiO with non-iridescent effect 2 The preparation method of structural color thin film, comprises the following steps:

[0043] 1) Preparation of modified PS colloidal microsphere emulsion: Purification of styrene, take 14mL of purified styrene solution, 1mL of α-methacrylic acid, and 90mL of deionized water in a three-necked round-bottomed flask, stir magnetically for 60min, and mix the solution , placed in an oil bath at 95°C, stirred magnetically for 60 minutes, injected with a concentration of 1.7g / mL, 10mL of potassium persulfate solution, and reacted at a constant temperature of 95°C for 9 hours to obtain a modified PS colloidal microsphere emulsion;

[0044] 2) Encapsulated TiO 2 Shell structure: Take one-third of the obtained modified PS colloidal microsphere emulsion, disperse it in a mixture of 80mL ethanol and 20mL acetonitrile, and record it as liquid A, dissolve 3mL butyl titanate (TBOT) in 16mL ethanol and 4mL In the mixed solution of acetonitrile, i...

Embodiment 2

[0047] A PS@TiO with non-iridescent effect 2 The preparation method of structural color thin film, comprises the following steps:

[0048] 1) Preparation of modified PS colloidal microsphere emulsion: Purification of styrene, take 10mL of purified styrene solution, 0.6mL of α-methacrylic acid, and 90mL of deionized water in a three-necked round-bottomed flask, stir magnetically for 30min, and make the solution Mix, put in an oil bath at 80°C, stir magnetically for 50min, inject 10mL of potassium persulfate solution at a concentration of 1.7g / mL, react at a constant temperature of 80°C for 8h, and obtain a modified PS colloidal microsphere emulsion;

[0049] 2) Encapsulated TiO 2 Shell structure: Take one-third of the obtained modified PS colloidal microsphere emulsion, disperse it in a mixture of 80mL ethanol and 20mL acetonitrile, and record it as liquid A, dissolve 2.0mL butyl titanate (TBOT) in 16mL ethanol and The mixture of 4mL acetonitrile is denoted as B solution; slo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com