Porous polymer with lipophobicity and pH responsiveness as well as preparation and application thereof

A porous polymer, responsive technology, used in other chemical processes, chemical instruments and methods, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a method for preparing a hydrophobic and oleophobic porous material, the steps are as follows:

[0042] (1) Mix 2.8g acrylamide, 0.5g N', N-methylenebisacrylamide, 8g F-127, 1.8mL diethylaminoethyl methacrylate was dissolved in 16.9g water to make an aqueous solution; 6.9mL 2-(perfluorooctyl)ethyl methacrylate was dissolved in 69.3mL toluene, stirred at 400rpm Next, the toluene solution was added to the above aqueous solution to form an emulsion, and then 0.3 g of ammonium persulfate and 0.16 mL of N,N,N,N-tetramethylethylenediamine were added to the emulsion.

[0043] (2) The above emulsion was polymerized at 40° C. for 1 hour. After the polymerization, water and toluene were removed and dried to obtain a hydrophobic and oleophobic porous material.

Embodiment 2

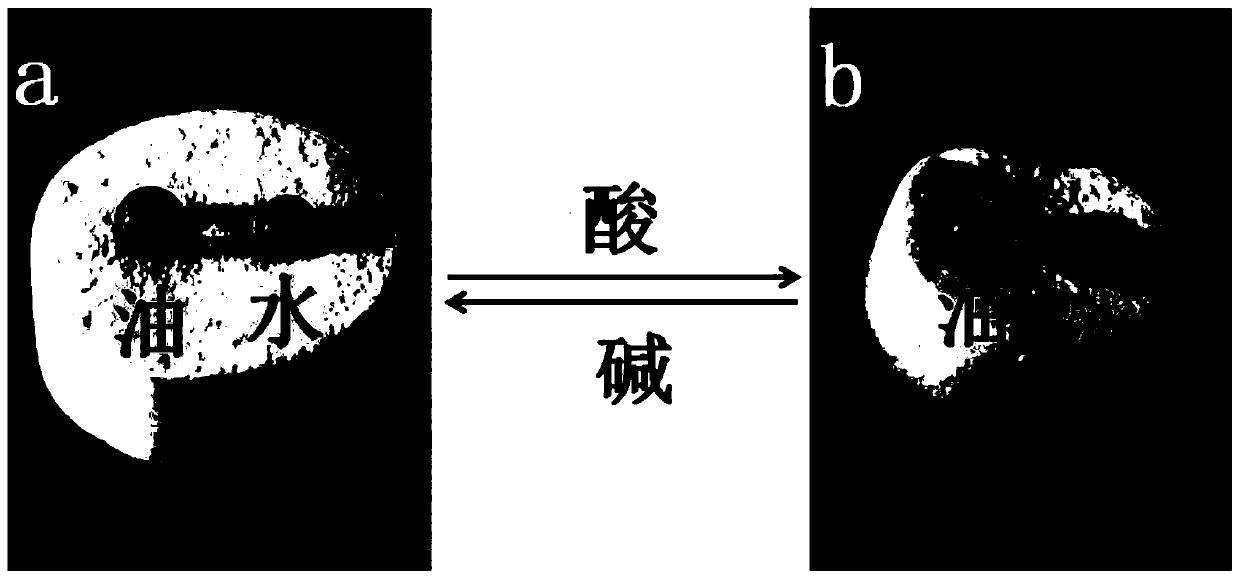

[0045] This embodiment provides a method for changing the hydrophobic and oleophobic porous material in Example 1 into a hydrophilic and oleophobic porous material by changing the pH,

[0046] The hydrophobic and oleophobic porous material prepared in Example 1 was soaked in 1 wt% HCl solution of water and ethanol for 1 hour, extracted with ethanol and dried to obtain a hydrophilic and oleophobic porous material.

Embodiment 3

[0048] This example provides a method for converting the hydrophilic and oleophobic porous material in Example 2 into the hydrophobic and oleophobic porous material in Example 1 by changing the pH.

[0049] The hydrophilic and oleophobic porous material prepared in Example 2 was soaked in a solution of 1 wt% triethylamine in water and ethanol for 1 hour, extracted with ethanol and dried to obtain a hydrophobic and oleophobic porous material.

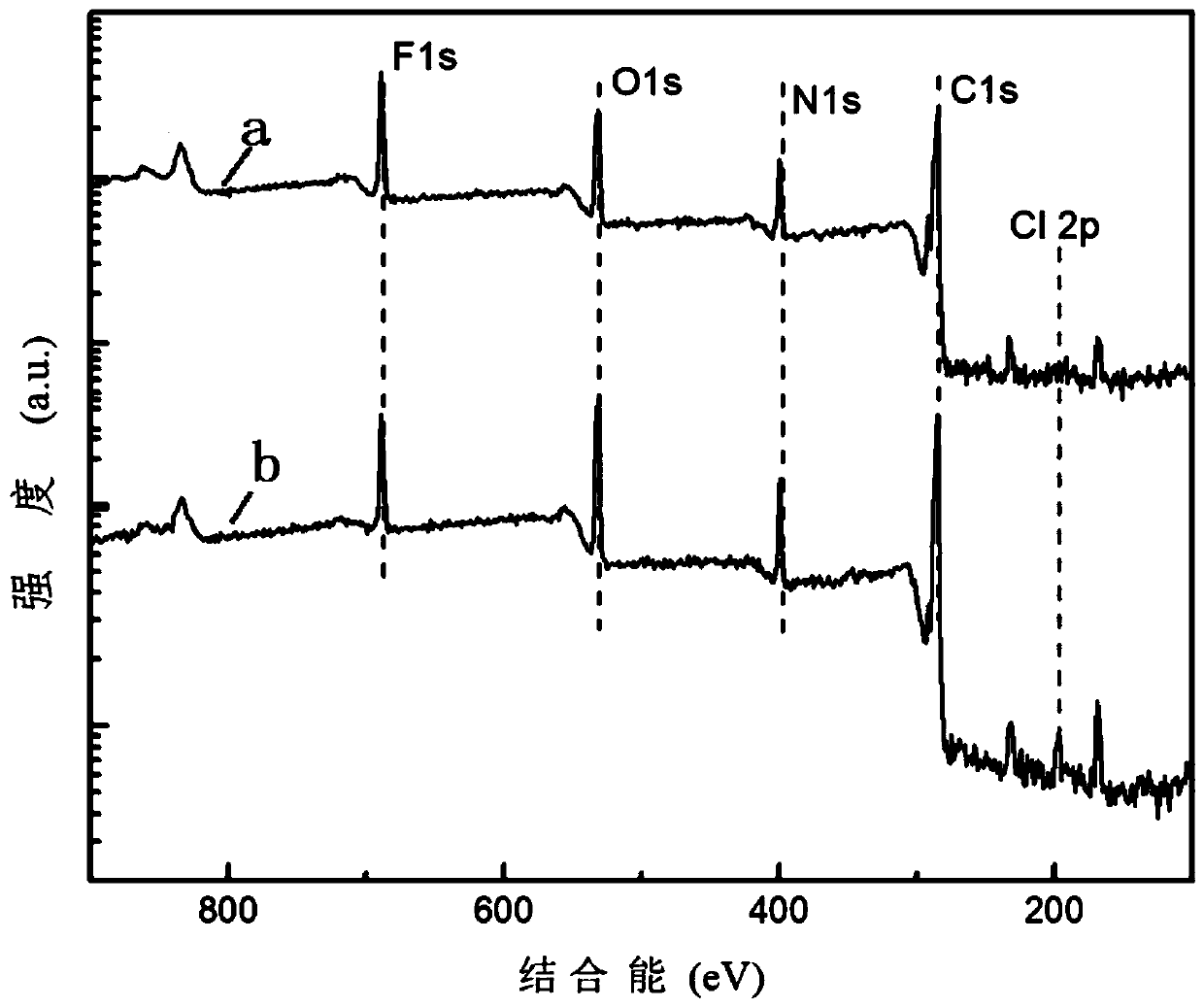

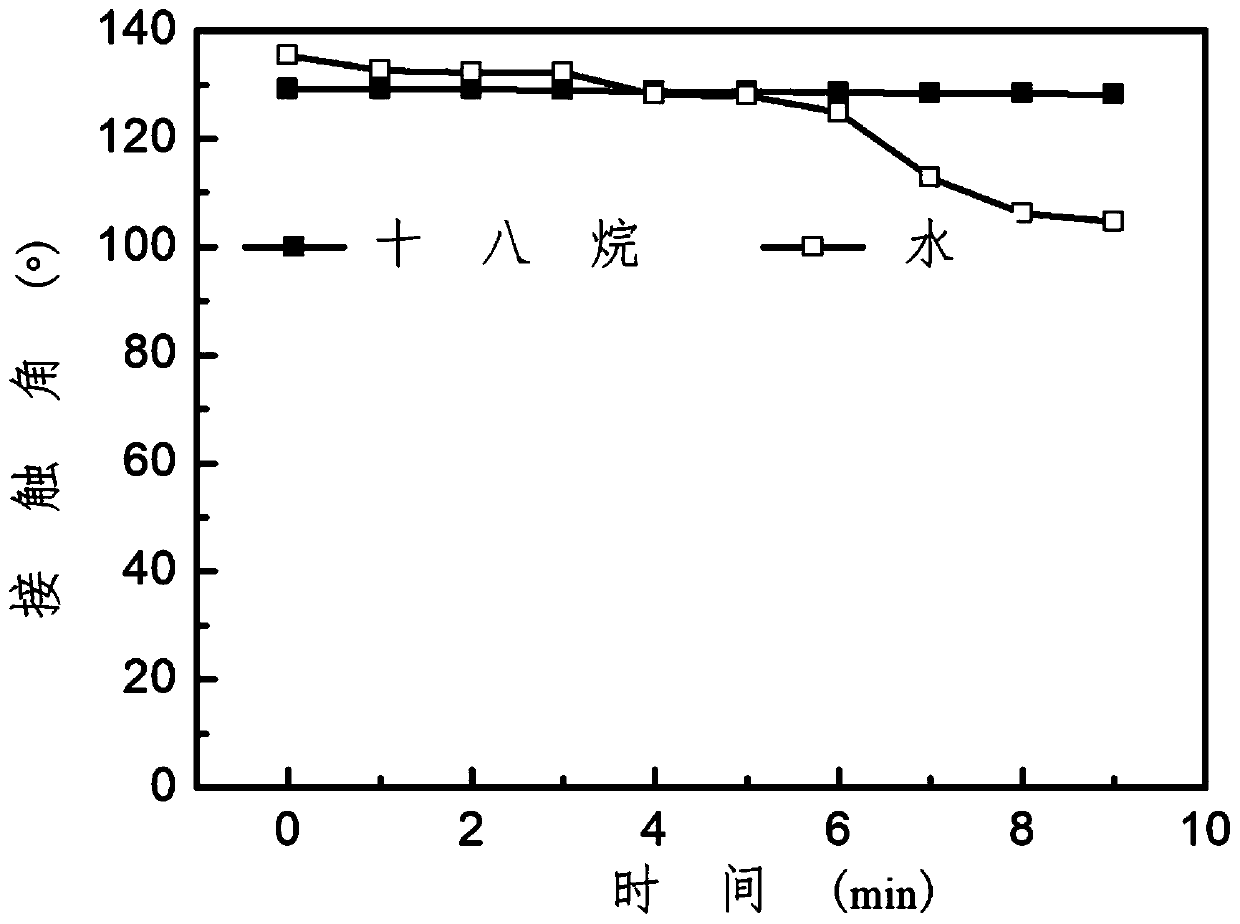

[0050] figure 1 Curves a and b are the electron spectrum diagrams of the hydrophobic and oleophobic porous materials in Example 1 and the hydrophilic and oleophobic porous materials in Example 2, respectively. figure 2 It is the test chart of the water and octadecane contact angle of the hydrophobic and oleophobic porous material of embodiment 1 as a function of time. As can be seen from the figure, the above-mentioned hydrophobic and oleophobic porous material has stable oleophobicity, and the contact angle of hexadecane on its surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com