A t360 suspension link bracket

A technology of connecting rod bracket and transverse tie rod, which is applied in the field of auto parts, can solve the problems of general oil resistance, reduced contact life of rubber dust cover and lubricant, etc., and achieve the effect of avoiding long-term contact and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

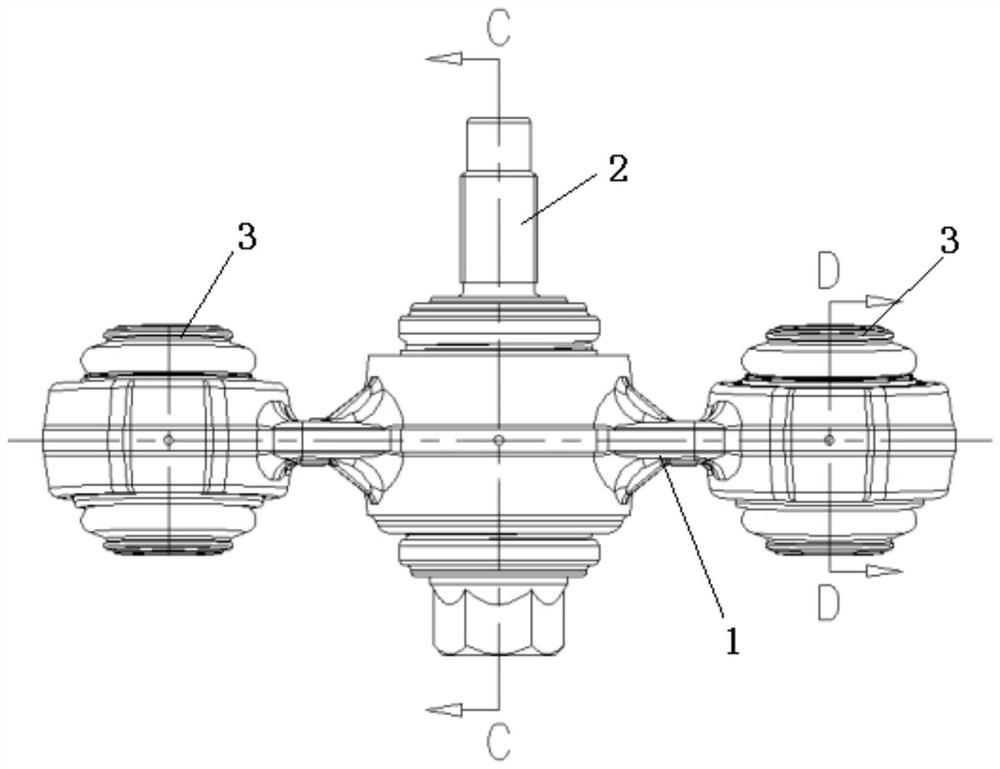

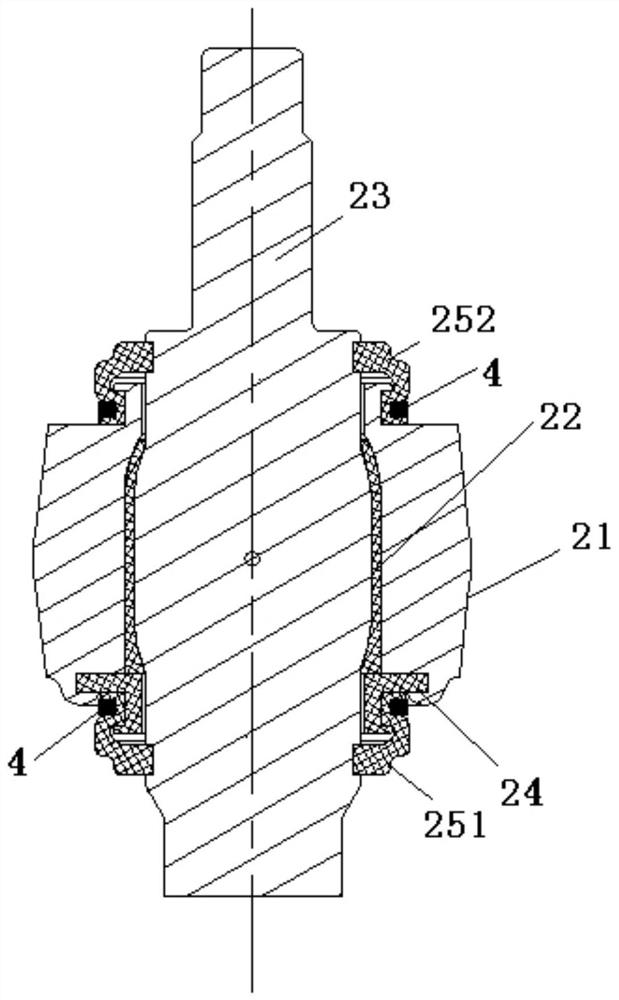

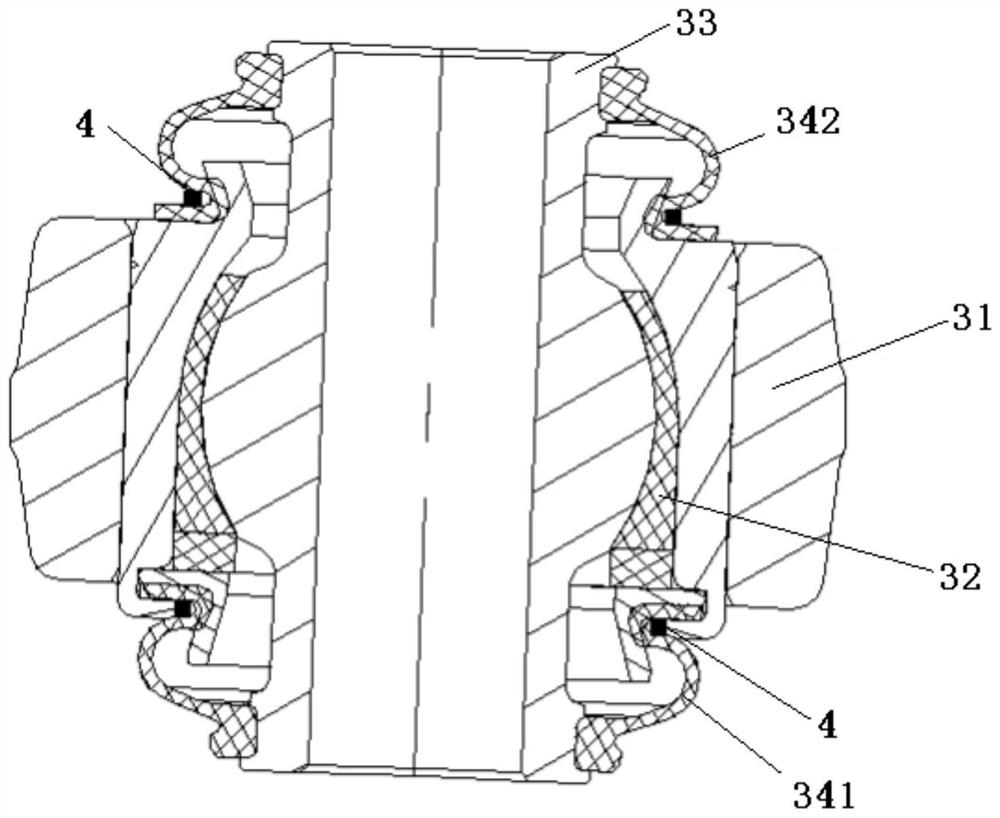

[0037] Combine below Figure 1-5 For further clarification:

[0038] A T360 suspension link bracket, comprising a back-rotating transverse tie rod body 1, a middle mechanism 2 is provided in the middle of the rear-rotating transverse tie rod body 1, side mechanisms 3 are provided on both sides of the back-rotating transverse tie rod body 1, and the middle mechanism 2 includes a middle ball The hinge bush 21, the middle ball seat 22 is arranged in the middle ball hinge bush 21, the pin 23 is arranged in the middle ball seat 22, the pin 23 and the bottom of the middle ball seat 22 are provided with a pressing ring 24, the pressing ring 24 and A first dust cover 251 is provided between the column pins 23, a second dust cover 252 is provided on the top of the column pins 23 and the middle spherical hinge bushing 21, and the side mechanism 3 includes a side spherical hinge bushing 31, a side spherical hinge A side ball seat 32 is arranged in the bushing 31, and a pin seat 33 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com