Preparation method of silica gel baking pad with good oleophobicity

An oleophobic and silica gel technology, applied in the field of silicone baking mat preparation, can solve the problems of shortened life, general oleophobicity, troublesome removal, etc., and achieve the effect of enhancing wear resistance, oleophobicity, and bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

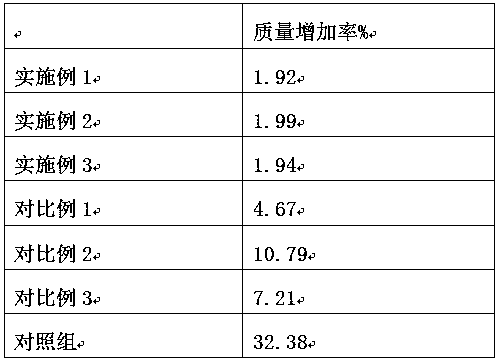

Examples

Embodiment 1

[0019] A method for preparing a silicone baking mat with good oleophobicity, comprising the following steps:

[0020] (1) Mix vinyl silicone oil, hydrogen-containing silicone oil, rosin resin grafted modified hydrogen-containing silicone oil, inhibitor, catalyst, modified nano-silica, and silane coupling agent, heat to 185°C, and rotate at 1800r / min After stirring and reacting for 2 hours, liquid silica gel was made;

[0021] (2) Let the liquid silica gel obtained above stand for 12 minutes, then use 500W, 40kHz ultrasonic waves to treat the liquid silica gel after standing for 5 minutes, and then continue to stand for 10 minutes to obtain pretreated liquid silica gel;

[0022] (3) Inject the pretreated liquid silica gel obtained above into the mold, and then dry it at 85°C for 2.5 hours. When the liquid silica gel in the mold forms a semi-solidified state, put it into the plasma reaction chamber, and the reaction chamber is vacuumed. Draw to 1.2×10 -3 Pa, introduce tetrafl...

Embodiment 2

[0032] A method for preparing a silicone baking mat with good oleophobicity, comprising the following steps:

[0033] (1) Mix vinyl silicone oil, hydrogen-containing silicone oil, rosin resin grafted modified hydrogen-containing silicone oil, inhibitor, catalyst, modified nano-silica, and silane coupling agent, heat to 190°C, and rotate at 1800r / min After stirring and reacting for 2 hours, liquid silica gel was made;

[0034] (2) Let the liquid silica gel obtained above stand for 14 minutes, then use 500W, 40kHz ultrasonic waves to treat the liquid silica gel after standing for 8 minutes, and then continue to stand for 12 minutes to obtain pretreated liquid silica gel;

[0035] (3) Inject the pretreated liquid silica gel obtained above into the mold, and then dry it at 85°C for 2.5 hours. When the liquid silica gel in the mold forms a semi-solidified state, put it into the plasma reaction chamber, and the reaction chamber is vacuumed. Draw to 1.2×10 -3 Pa, introduce tetrafl...

Embodiment 3

[0045] A method for preparing a silicone baking mat with good oleophobicity, comprising the following steps:

[0046] (1) Mix vinyl silicone oil, hydrogen-containing silicone oil, rosin resin grafted modified hydrogen-containing silicone oil, inhibitor, catalyst, modified nano-silica, and silane coupling agent, heat to 188°C, and rotate at 1800r / min After stirring and reacting for 2 hours, liquid silica gel was made;

[0047] (2) Let the liquid silica gel obtained above stand for 13 minutes, then use 500W, 40kHz ultrasonic waves to treat the liquid silica gel after standing for 6 minutes, and then continue to stand for 11 minutes to obtain pretreated liquid silica gel;

[0048] (3) Inject the pretreated liquid silica gel obtained above into the mold, and then dry it at 85°C for 2.5 hours. When the liquid silica gel in the mold forms a semi-solidified state, put it into the plasma reaction chamber, and the reaction chamber is vacuumed. Draw to 1.2×10 -3 Pa, introduce tetrafl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com