Alkali-resisting penetrating agent for cotton fabric mercerization

An alkali-resistant penetrant, cotton fabric technology, applied in the direction of plant fibers, textiles and papermaking, fiber processing, etc., can solve the problems of low conversion rate of sulfuric acid method, high salt content in products, complicated operation, etc., to improve the absorption of dyes. Ability, low inorganic salt content, light color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the alkali-resistant mercerizing penetrating agent is characterized in that: it is carried out according to the following steps, 25-80 parts of one kind of fatty alcohol or multiple mixed fatty alcohols, 45-150 parts of fatty alcohol ether (EO: 7-10) are placed in In a 500ml three-necked flask, start stirring, add 2-45 parts of a catalyst or composite catalyst and 60-100 parts of sulfamic acid, connect the condenser to reflux, heat up to 120°C and start timing, keep warm for 120 minutes, and cool down to 100°C Slowly add 100 parts of soft water, and adjust the pH to 8.5 with sodium hydroxide aqueous solution after the reaction materials are stirred evenly.

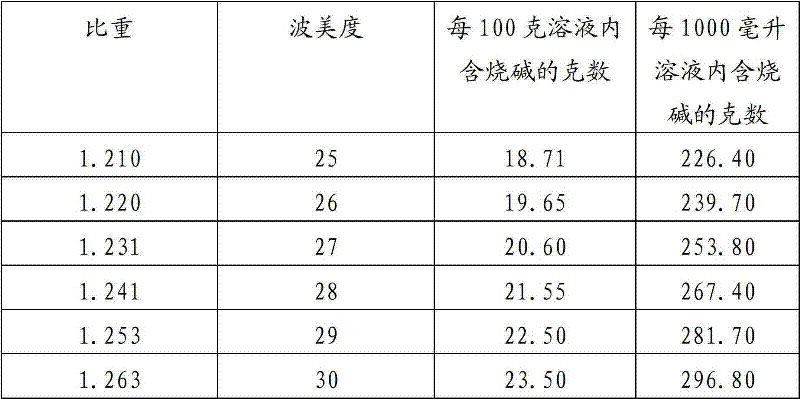

[0024] Alkali resistance penetration evaluation method:

[0025] The evaluation method adopts the canvas piece sedimentation method-put the cut canvas piece of 2cm×2cm into the working solution (99.0g of sodium hydroxide aqueous solution, add 1.0g of penetrant, and stir well), and calculate...

Embodiment 1

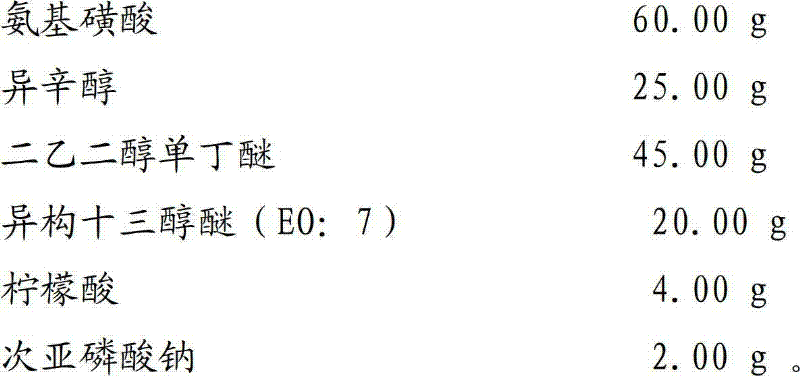

[0029] An alkali-resistant penetrating agent for mercerizing cotton fabrics, comprising the following components, by weight (g),

[0030]

[0031] Measurement: Penetration time at 25 Baume degrees: 17.6 seconds

[0032] Penetration time at 28 Baume degrees: 20.8 seconds.

Embodiment 2

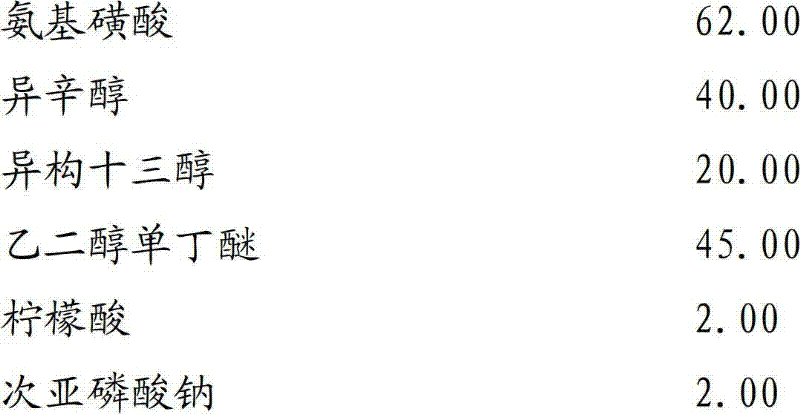

[0034] An alkali-resistant penetrating agent for mercerizing cotton fabrics, comprising the following components, by weight (g),

[0035]

[0036] Penetration time at 25 Baume degrees: 8.9 seconds

[0037] Penetration time at 28 Baume: 12.5 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com