Velvety composite filament wash-faded plus material

A composite silk and fabric technology, applied in the direction of fabric surface trimming, textile and papermaking, roughening, etc., can solve the problems of loose and not firm hand, unsatisfactory surface sanding uniformity and velvet feeling, and intolerant of rinsing, etc. The surface sanding condition is uniform and stable, good moisture absorption and ventilation performance, and the effect of uniform washing and fading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below through specific embodiments.

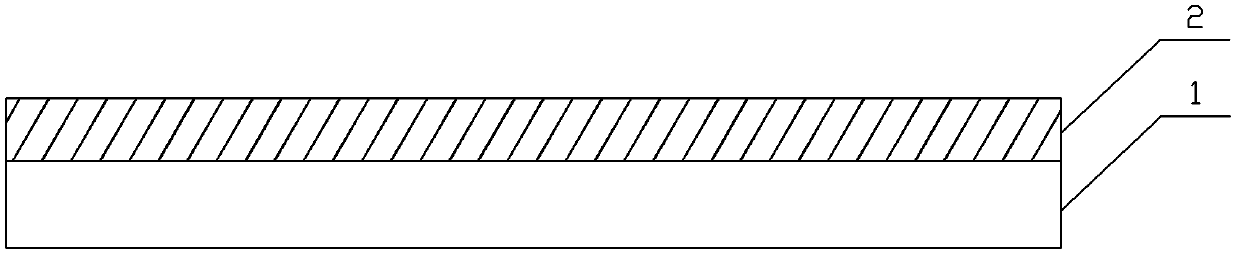

[0024] refer to figure 1 , a velvet composite silk wash-off fabric, the fabric includes a base fabric layer 1 woven from polyester-nylon composite fibers and cotton fibers and a wash-off layer 2 coated on the surface of the base fabric layer 1, the wash-off layer Layer 2 is formed by scraping and coating a layer of wash-off slurry on the surface of base cloth layer 1. The wash-off slurry is 10 parts by weight of modified acrylate, 90 parts by weight of water with a pH value of 6-7, 0.3 Parts by weight of polyethylenimine crosslinking agent, 0.3 parts by weight of silicone leveling agent, 0.2 parts by weight of polyether defoamer and 5 parts by weight of water-based environmentally friendly color paste are simply mixed and stirred by a mixer, and then 2.5 parts by weight are added while stirring It is prepared by stirring one part of PTF thickener for 20-30 minutes. Due to the low sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com