Plastic bag packaging machine

A packaging machine and plastic bag technology, applied in the field of packaging equipment, can solve the problems of easy wrinkling, unsightly products, unfavorable packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

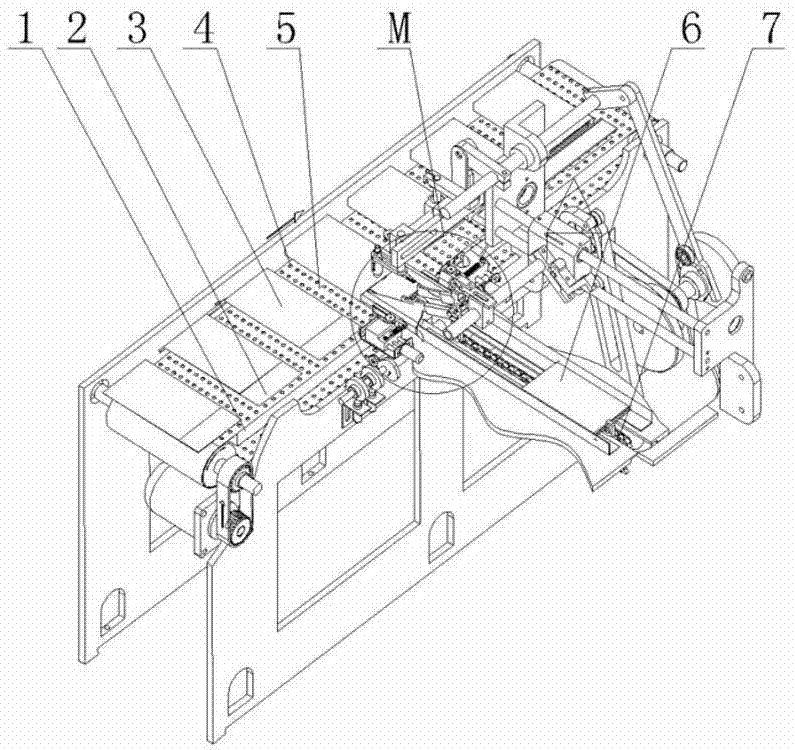

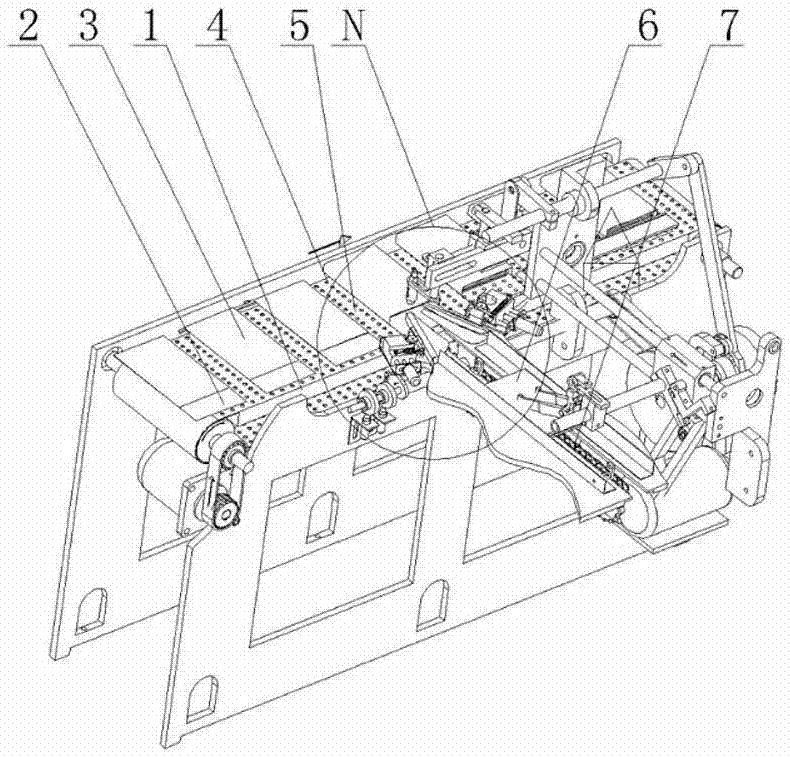

[0017] With reference to accompanying drawing, this plastic plastic bag encapsulating machine comprises plastic plastic bag feeding belt 5, package conveyer belt 7, and described plastic plastic bag feeding belt 5 is installed on the frame 1, and on described plastic plastic bag feeding belt 5 With adsorption hole 4, there is a negative pressure mechanism under the plastic bag feeding belt 5, which cooperates with the adsorption hole 4, and the plastic bag 3 sent over is adsorbed on the plastic bag feeding belt 5, so as to maintain the stability of feeding, The plastic bag feeding belt 5 and the package conveying belt 7 all move in gaps, which also belong to the known technology and will not be described in detail.

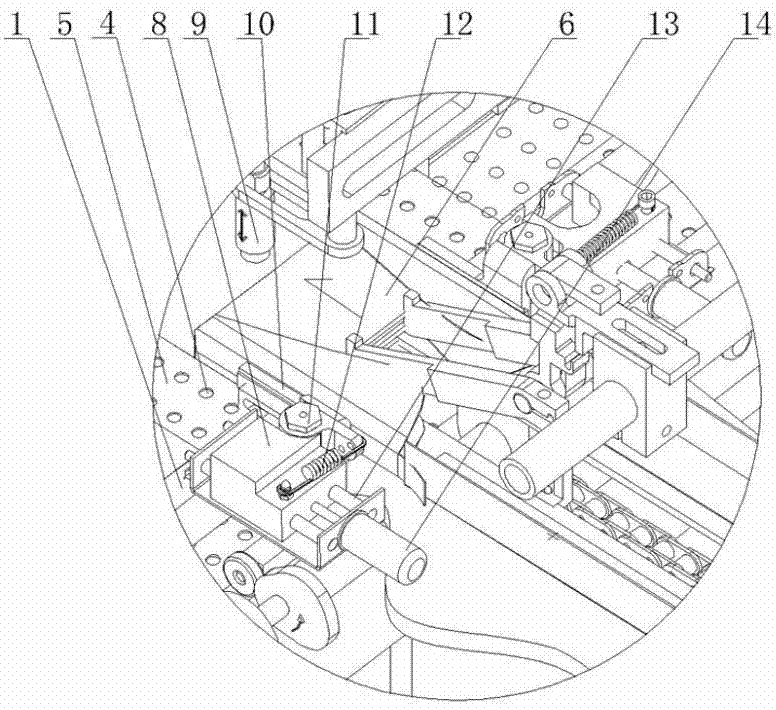

[0018] The frame 1 is provided with a bag support structure, and the bag support mechanism includes a symmetrically installed sliding block 8, which is located on both sides of the end of the packaging conveyor belt 7, and on the sliding block 8 A swing arm 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com