Bamboo fiber label tape and production method thereof

A trademark tape and bamboo fiber technology, applied in the direction of fiber treatment, plant fiber, continuous treatment of textile materials, etc., can solve the problems that need to be improved, and achieve the effect of good elasticity, soft hand feeling and not easy to wrinkle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

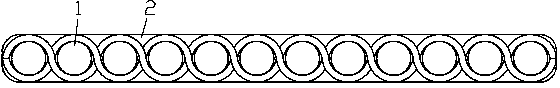

Image

Examples

Embodiment 1

[0045] Select bamboo fiber semi-finished products as the base cloth; then carry out anti-wrinkle finishing: specifically, the base cloth is dipped in the finishing solution, and then baked at 120°C for 3 minutes; the finishing solution is polymaleic acid 140g / L, sub- Sodium phosphate 40g / L, organosilicon softener 2g / L, penetrant JFC 0.2g / L; the baking adopts continuous segmental baking, specifically the method of heating up and then cooling down, and the temperature is controlled at 120°C; continuous segmental baking is specific An 8-section oven is used, and the oven temperatures are 100°C, 120°C, 140°C, 160°C, 170°C, 160°C, 140°C, and 120°C.

[0046] Pre-calendering treatment: pre-calendering the base fabric after anti-wrinkle finishing. The calendering surface is a satin surface. The calendering temperature is 50°C, the pressure is 10MPa, and the calendering speed is 30m / min. The thickness is 0.285mm;

[0047]Coating treatment: using dry coating method, sizing on the plain...

Embodiment 2

[0051] Select bamboo fiber semi-finished products as the base cloth; then carry out anti-wrinkle finishing: specifically, the base cloth is dipped in the finishing solution, and then baked at 175°C for 5 minutes; the finishing solution is polymaleic acid 160g / L, sub- Sodium phosphate 50g / L, organosilicon softener 10g / L, penetrant JFC 2g / L; the baking adopts continuous segmental baking, specifically the method of heating up and then cooling down, and the temperature is controlled at 170°C; the continuous segmental baking is specifically Eight ovens are used, and the oven temperatures are 100°C, 120°C, 140°C, 160°C, 170°C, 160°C, 140°C, and 120°C.

[0052] Pre-calendering treatment: pre-calendering the base fabric after anti-wrinkle finishing, the calendering surface is a satin surface, the calendering temperature is 60°C, the pressure is 12MPa, the calendering speed is 35m / min, and the base fabric is pressed to The thickness is 0.295mm;

[0053] Coating treatment: using dry co...

Embodiment 3

[0056] Select bamboo fiber semi-finished products as the base cloth; then carry out anti-wrinkle finishing: specifically, the base cloth is dipped in the finishing solution, and then baked at 155° C. for 4 minutes; the finishing solution is polymaleic acid 150g / L, sub- Sodium phosphate 60g / L, organosilicon softener 6g / L, penetrant JFC 2g / L; the baking adopts continuous segmental baking, specifically the method of heating up and then cooling down, and the temperature is controlled at 150°C; the continuous segmental baking is specifically Eight ovens are used, and the oven temperatures are 100°C, 120°C, 140°C, 160°C, 170°C, 160°C, 140°C, and 120°C.

[0057] Pre-calendering treatment: pre-calendering the base fabric after anti-wrinkle finishing, the calendering surface is a satin surface, the calendering temperature is 55°C, the pressure is 11MPa, the calendering speed is 32m / min, and the base fabric is pressed to The thickness is 0.285-0.295mm;

[0058] Coating treatment: using...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com