Magnetron sputtering reeling coater for large-area flexible substrate

A magnetron sputtering and flexible substrate technology, which is applied in the field of large-area flexible substrate magnetron sputtering coil coating machines, can solve the problems of large thermal load and film wrinkling, and achieves high production efficiency and is not easy to wrinkle. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

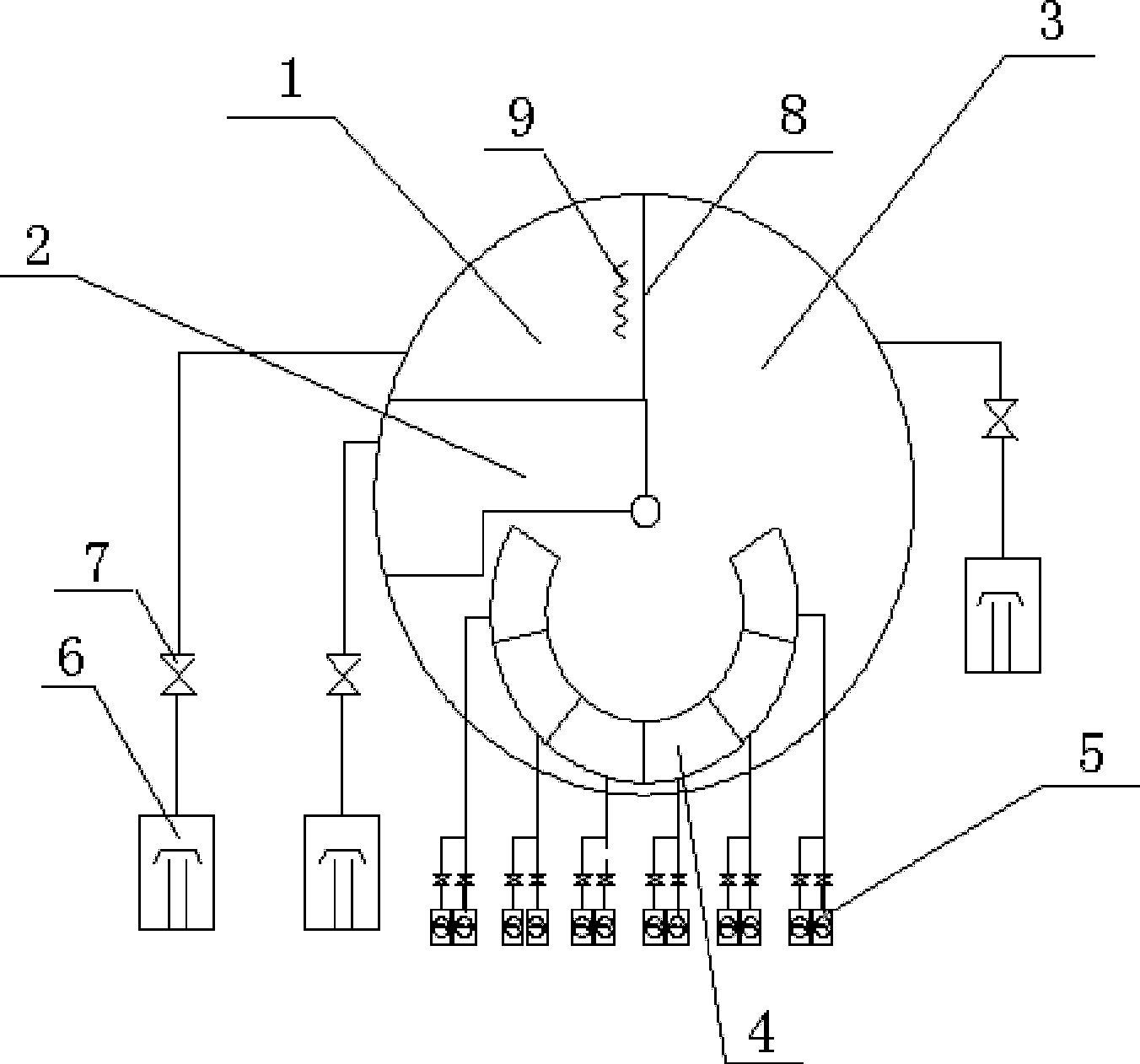

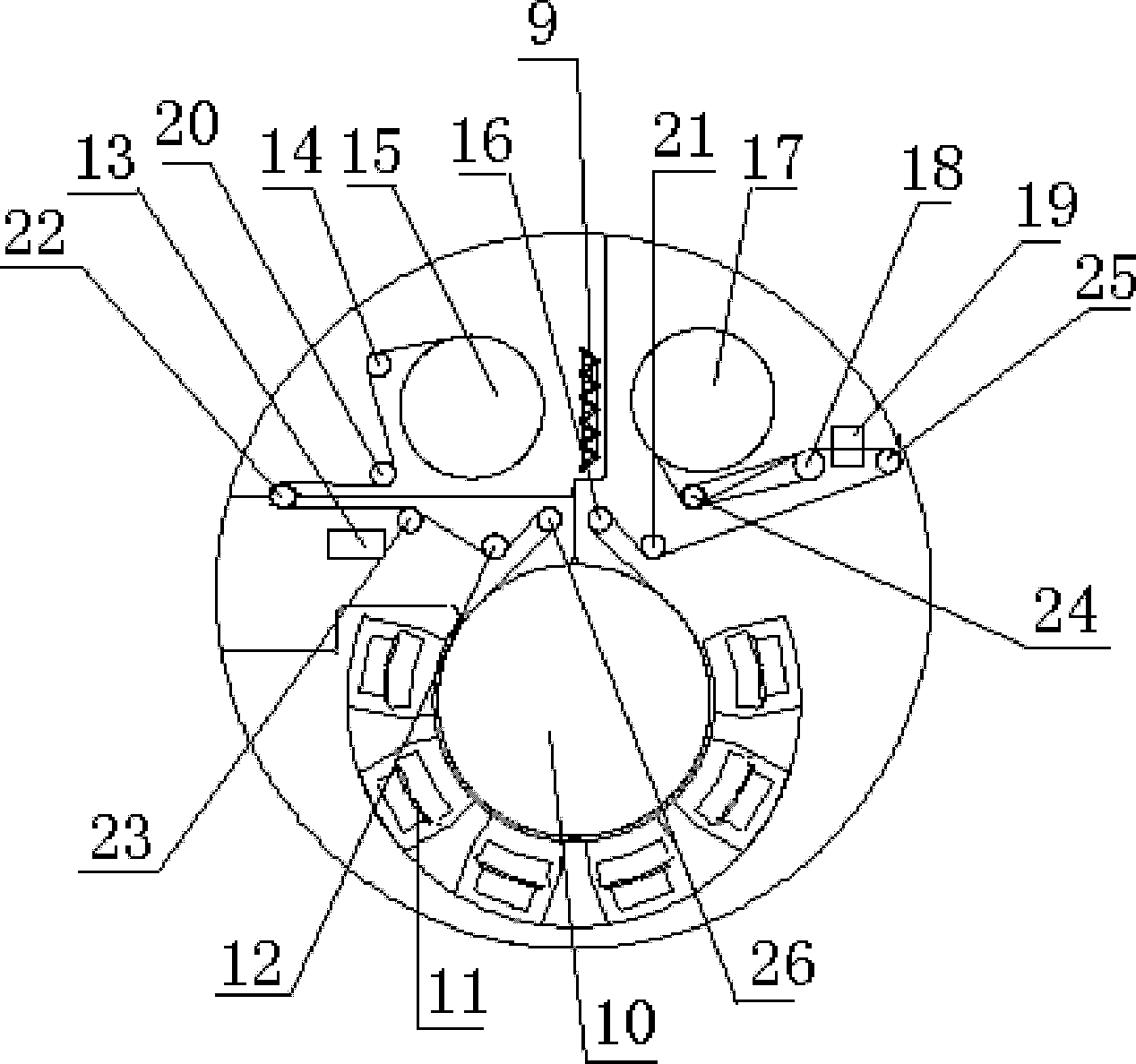

[0017] Such as figure 1 , figure 2 As shown, a large-area flexible substrate magnetron sputtering roll-to-roll coating machine includes a circular vacuum chamber, a flexible substrate winding system and a magnetron sputtering source, wherein the circular vacuum chamber is fixed, and the flexible substrate roll The winding system and the magnetron sputtering source can be stretched into or pulled out from the two sides of the circular vacuum chamber respectively; the circular vacuum chamber is divided into unwinding area 1, front The processing area 2 and the winding area 3, and the unwinding area 1, the pre-processing area 2 and the winding area 3 are all connected to the diffusion pump 6 through the vacuum valve 7, and a cryogenic water vapor trap is installed in the unwinding area 1 The tube 9 is also provided with a semicircular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com