Pump and its mfg. method

A manufacturing method and technology of a pump chamber, which are applied in the directions of pumps, pump components, variable displacement pump components, etc., can solve the problem that the upper frame body cannot be designed extremely thin, the flow path 53 is not easily formed, and the pump body processing qualification rate is low, etc. problem, to achieve the effect of good material utilization, air tightness, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

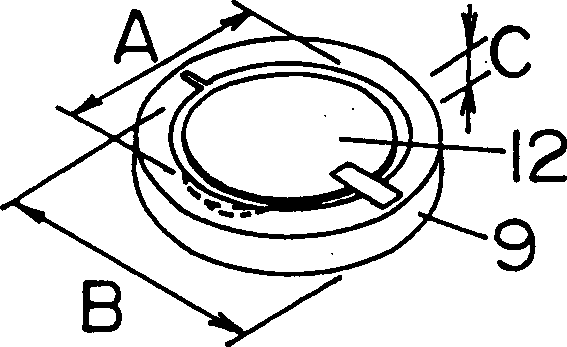

[0112] figure 1 4 shows a diaphragm type pump, which is composed of a disc-shaped diaphragm 12 , a disc-shaped case 9 and a check valve unit 8 . The diaphragm 12 is placed on the upper surface of the case body 9 , and the periphery of the diaphragm 12 is fixed by welding or bonding on the upper surface of the case body 9 , and the pump chamber 1 is formed between the diaphragm 12 and the upper surface of the case body 9 .

[0113] The size of the pump, for example, the outer diameter A of the vibrating membrane 12 is φ20mm, the outer diameter B of the box body 9 is φ22mm, and the height C is 3mm.

[0114] In the case body 9 , a suction side flow path 2 that sucks into the pump chamber 1 and a discharge side flow path 3 that discharges from the pump chamber 1 are formed along the thickness direction of the case body 9 . A check valve accommodating portion 18 is provided between the pump chamber 1 and the flow paths 2 and 3 , and the check valve unit 8 is accommodated and moun...

Embodiment 2

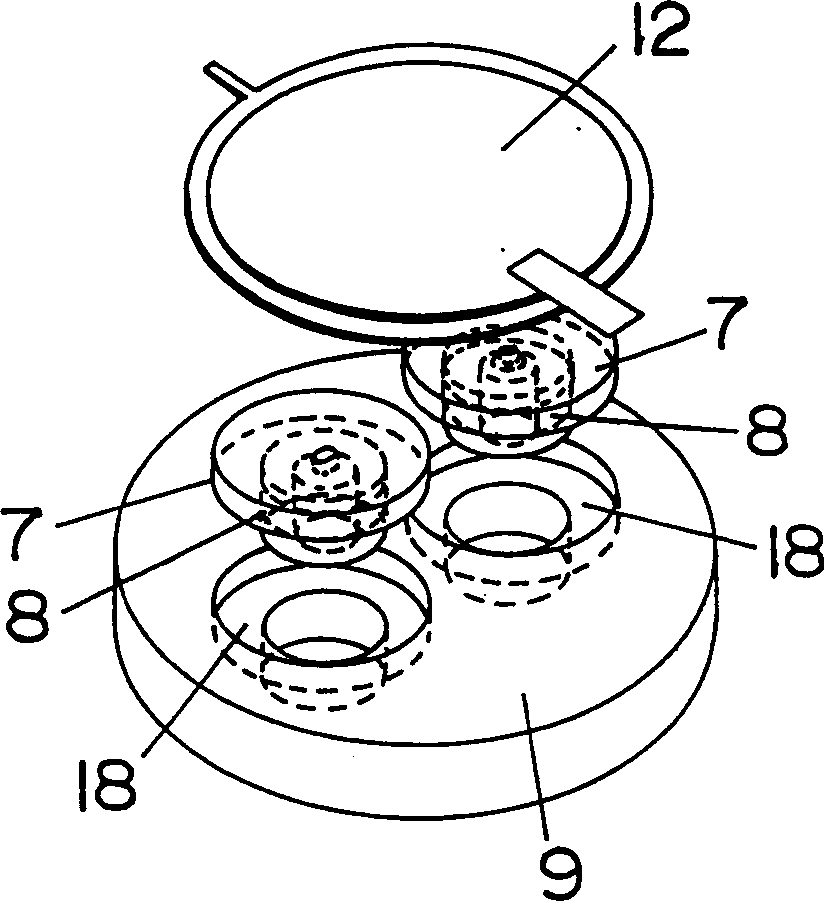

[0122] Figure 5A and Figure 5B This shows an embodiment in which the fluid suction side check valve unit 8 and the fluid discharge side check valve unit 8 have the same shape, and the check valve unit 8 is installed in the case body 9 up and down on the suction side and the discharge side.

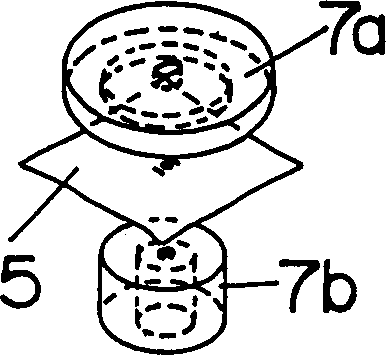

[0123] As in the first embodiment, the check valve frame 7 is formed by the first spacer 7a and the second spacer 7b, but in this embodiment, the first spacer 7a and the second spacer 7b are formed to have the same thickness , Disc shape with the same outer diameter. A check valve membrane 5 is installed between the first spacer 7a and the second spacer 7b, and the check valve membrane 5 is provided as a bendable large-diameter space 19 on the first spacer 7a. Furthermore, the check valve unit 8 is mounted on the suction side so that the first spacer 7a side is formed on the pump chamber 1 side, and the check valve unit 8 is mounted on the discharge side so that the second spacer 7b is...

Embodiment 3

[0126] Figure 6A and Figure 6B An example is shown in which the check valve unit 8 is installed in the case 9 from the side opposite to the installation surface of the diaphragm 12 .

[0127] like Figure 6A and Figure 6B As shown, the check valve housing 7 is formed of a first spacer 7a, a second spacer 7b, and a third spacer 7c. The third spacer 7c is made of PC resin like the first spacer 7a and the second spacer 7b.

[0128] A check valve film 5 is installed between the first spacer 7a and the second spacer 7b, and a flexible space 19 for the check valve film 5 is provided on the side of the first spacer 7a in the suction side check valve unit 8, A flexible space 19 for the check valve diaphragm 5 is provided on the side of the second spacer 7 b in the check valve unit 8 on the discharge side.

[0129] In this embodiment, since the check valve unit 8 is inserted from the side opposite to the installation surface of the vibrating film 12 of the case body 9, and inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com