Composite punching film and its producing method

A production method and technology of perforated film, applied in the field of sanitary fabrics, can solve problems such as poor elasticity and softness, increase production links, and low efficiency, achieve good elasticity and three-dimensional effect, reduce contact area, and have good absorption and permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

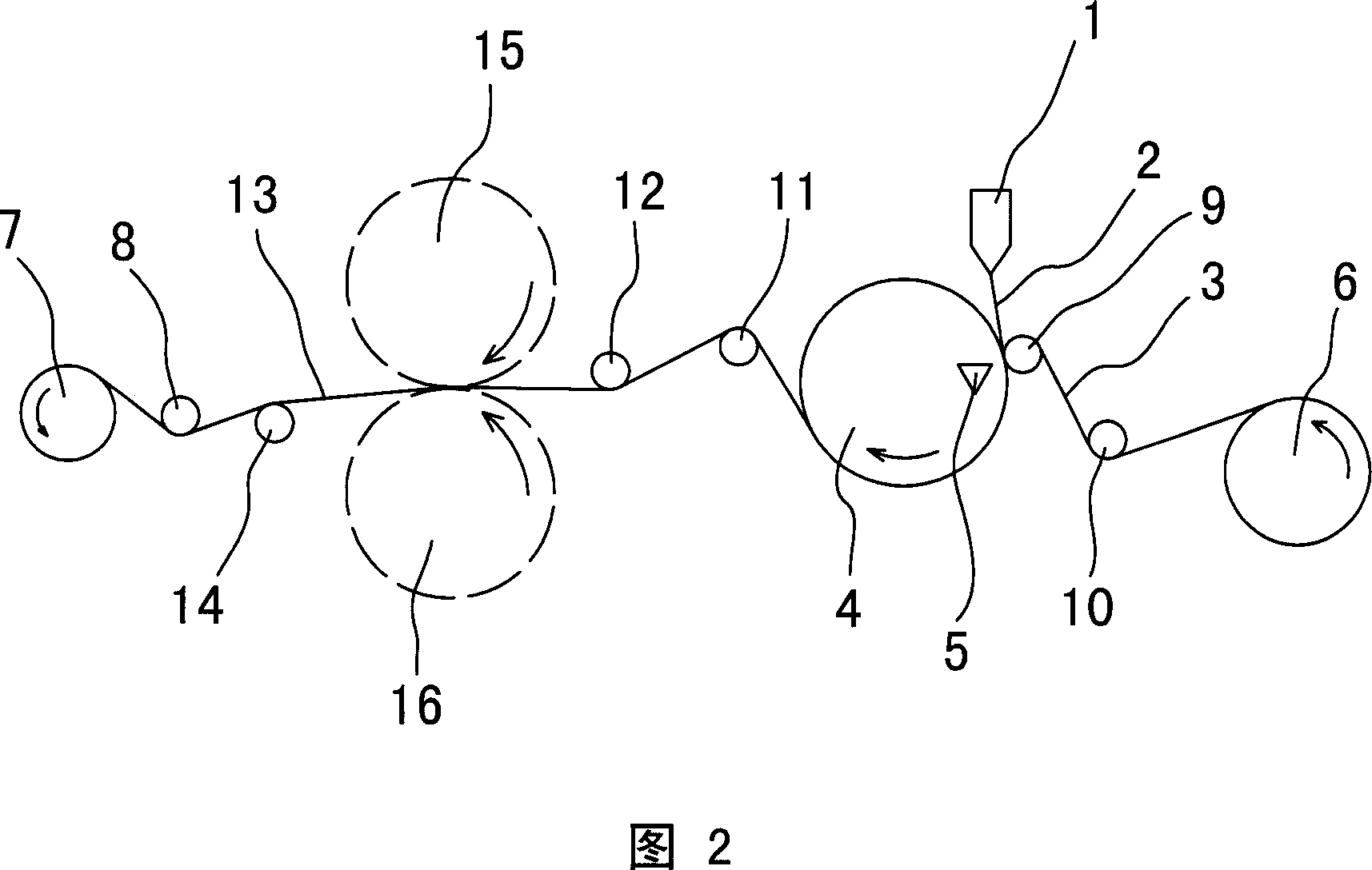

Method used

Image

Examples

Embodiment 1

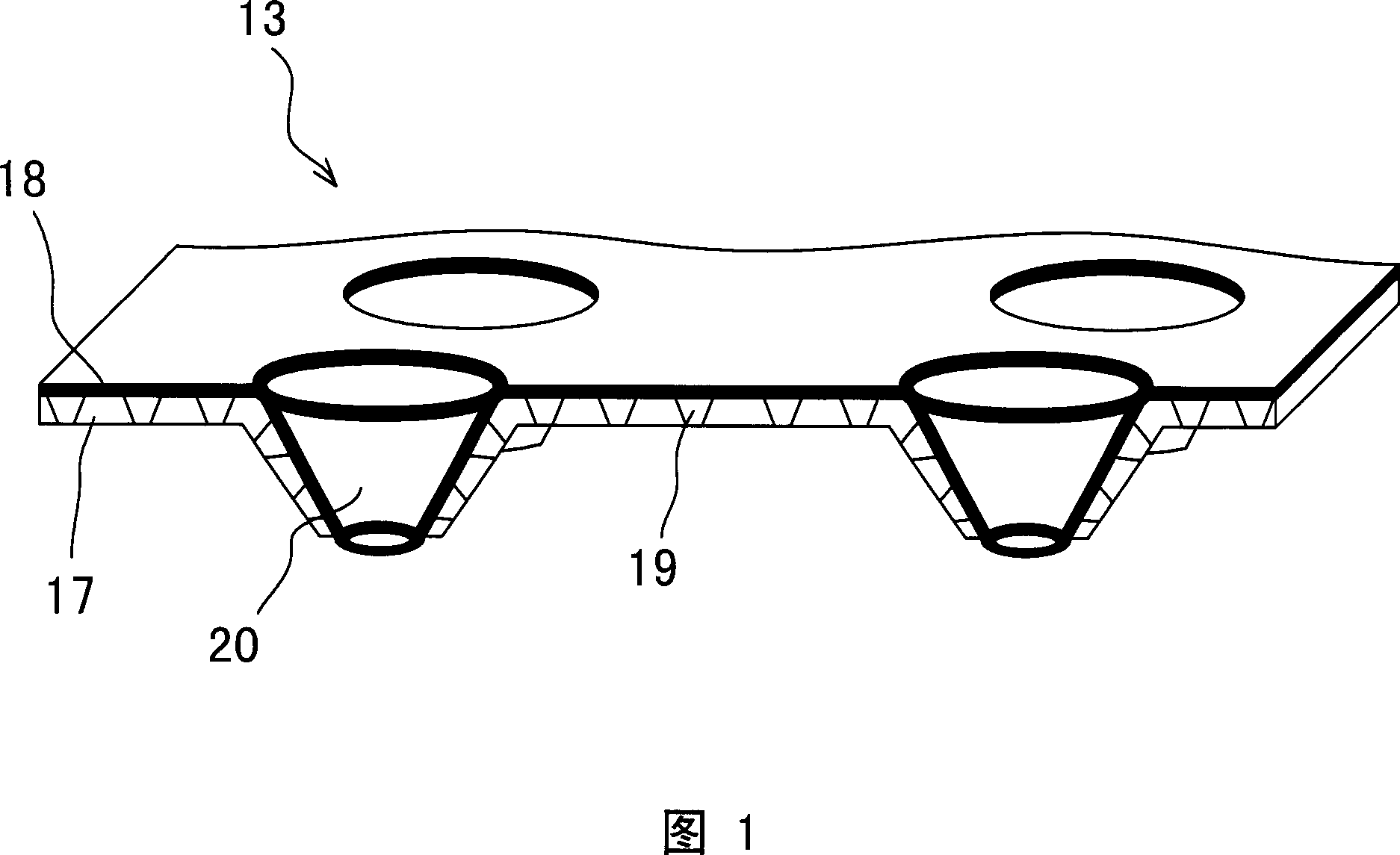

[0034] Embodiment one: two-layer composite perforated film and its preparation method

[0035] 1. Two-layer composite perforated film

[0036] As shown in Figure 1, the two-layer composite perforated film 13 is composed of the plastic film layer 17 of the lower floor and the non-woven fabric layer 18 of the upper floor. The film face of plastic film layer 17 offers the small mesh 19 of uniform distribution, and the aperture of small mesh 19 is 0.1mm, and opening density is 230 holes / cm 2 , The porosity is 30%. The membrane face of composite perforated membrane 13 is provided with evenly distributed large mesh 20, and the aperture of large mesh 20 is 2mm, and the opening density is 9 holes / cm 2 , The porosity is 35%. The hole pattern of the large mesh 20 is funnel-shaped, and the funnel protrudes downwards, and the small mesh 19 is arranged on the cone surface. The small mesh 19 is circular, the large mesh 20 is conical, and the small mesh 19 and the large mesh 20 can also ...

Embodiment 2

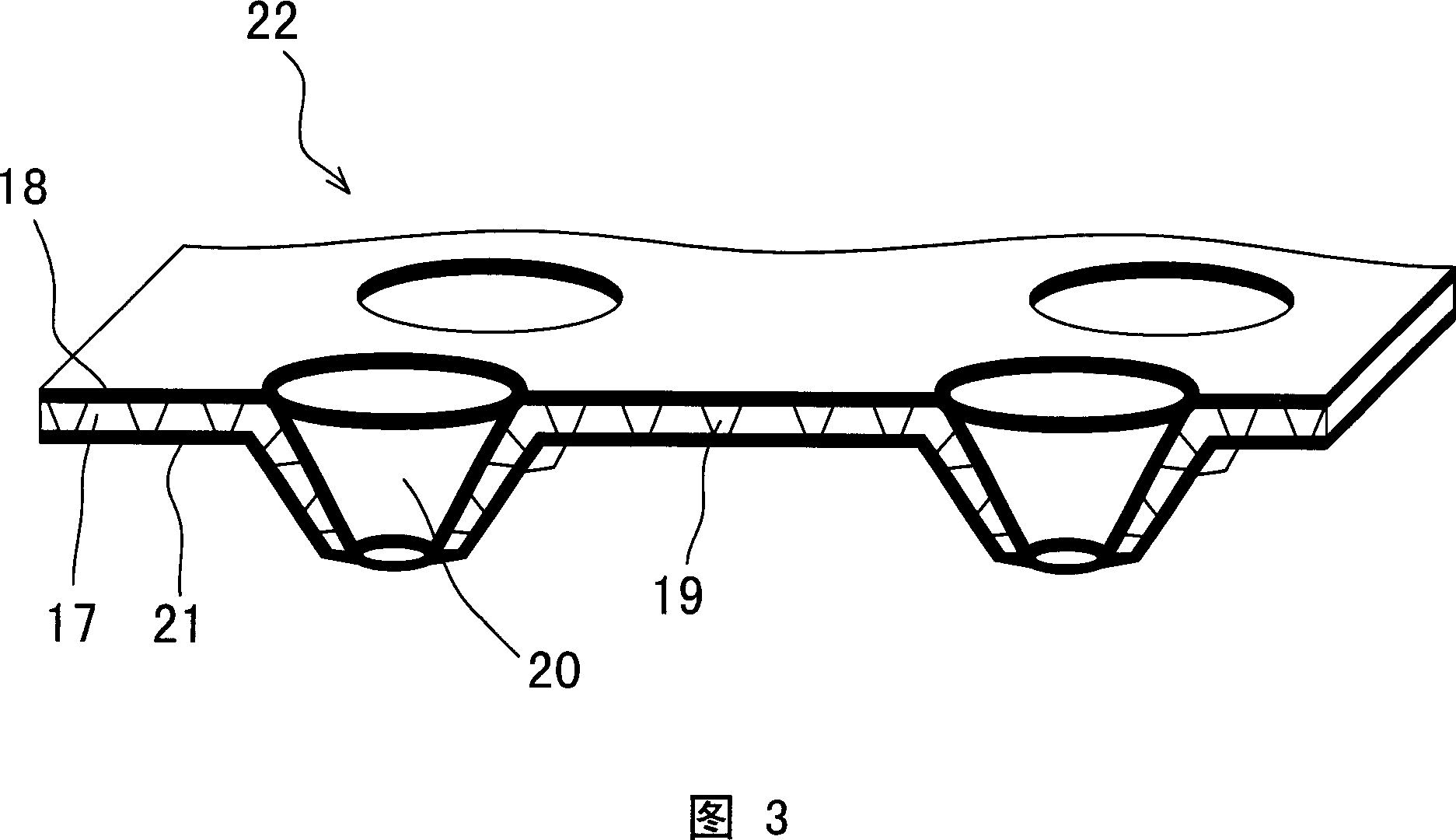

[0043] Embodiment two: three-layer composite perforated film and its manufacturing method

[0044] 1. Three-layer composite perforated film

[0045] As shown in Fig. 3, the three-layer composite perforated film 22 is composed of an upper non-woven fabric layer 18, a middle plastic film layer 17 and a lower non-woven fabric layer 21. The film face of plastic film layer 17 offers the small mesh 19 of uniform distribution, and the aperture of small mesh 19 is 0.2mm, and opening density is 180 holes / cm 2 , The porosity is 28%. The membrane face of composite perforated membrane 22 is provided with evenly distributed large mesh 20, and the aperture of large mesh 20 is 3mm, and the opening density is 6 holes / cm 2 , The porosity is 28%. The hole pattern of the large mesh 20 is funnel-shaped, and the funnel protrudes downwards, and the small mesh 19 is arranged on the cone surface. The small mesh 19 is circular, the large mesh 20 is conical, and the small mesh 19 and the large mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com