Kelp hanging, airing and drying device and working method thereof

A drying device and kelp technology, which is applied to heating devices, drying chambers/containers, local agitation dryers, etc., can solve problems such as poor sanitation, heavy workload, and kelp containing sediment, so as to save water and energy consumption, The effect of fast suspension speed and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the drawings and specific embodiments.

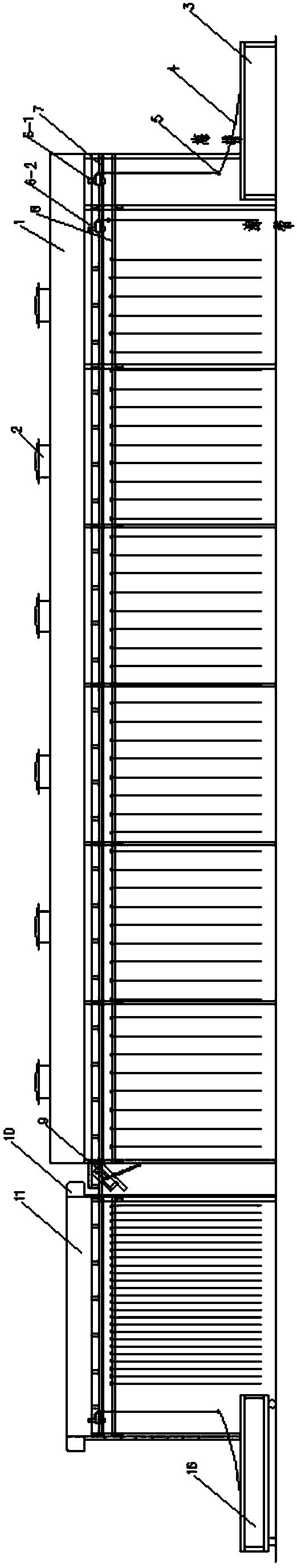

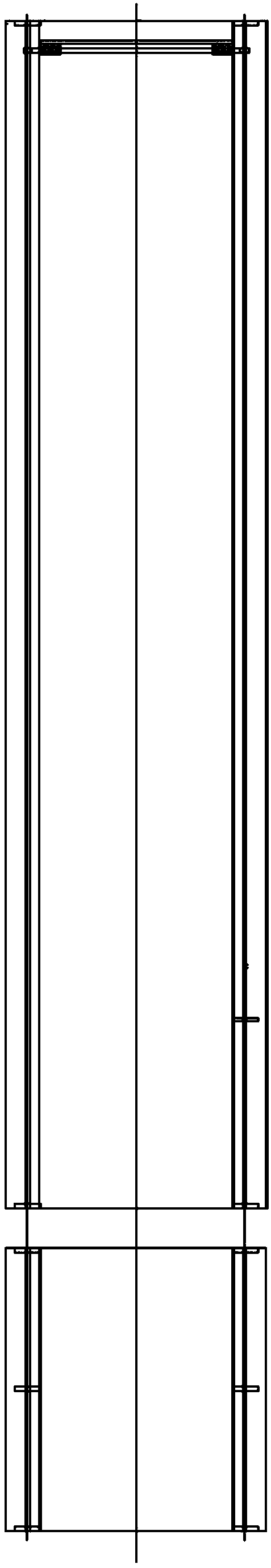

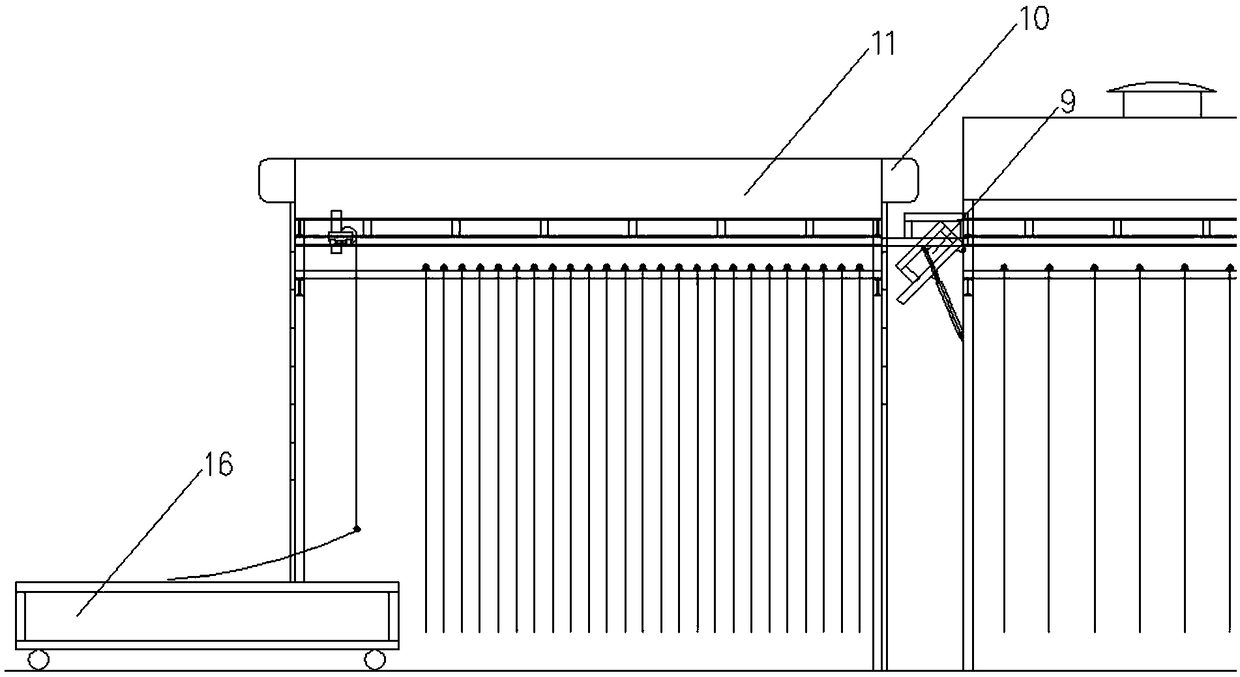

[0035] Such as Figure 1-6 Shown: when the kelp is dried, the bundles of kelp are hoisted to the operating platform 3. The operator hangs the bunches of kelp 4 on the drying pole 5 on the platform. A lifting and lifting instruction is issued, and the first hoist 6-1 in the drying and drying shed 1 slowly lowers the lifting components 12 on both sides. When it comes into contact with the drying rod 5, it is energized, and the drying rod 5 is sucked firmly by a magnetic force and lifted higher than the drying After the height of the rack 8 is moved to the left by a distance of 500 mm, the drying rod is placed in the initial placement position of the drying rack, and the initial lifting position is transplanted, and the new kelp drying rod is lifted. The second hoist 6-2 arrives at the initial position, put down the lifting parts, suck up the drying rack of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com