Quantum dot film and preparation method therefor

A quantum dot film and quantum dot technology, applied in the field of quantum dot film and its preparation, can solve the problem of high production cost of quantum dot film, and achieve the effect of not easy to wrinkle and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

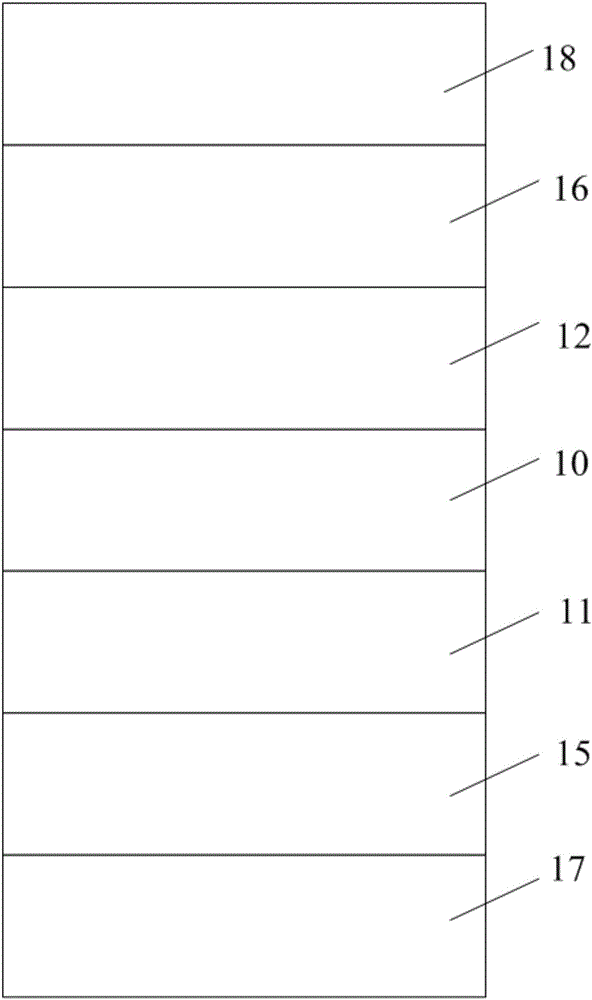

[0032] In the above-mentioned process of preparing the quantum dot film, the liquid quantum dot colloid is first solidified to form a quantum dot layer, and then other film layers are arranged on the quantum dot layer. The first curing step avoids the flow of the liquid quantum dot colloid, and the subsequent The preparation process does not require extremely precise molds and precise processing technology to control its uniformity, which makes the preparation cost of the quantum dot film lower, and the quantum dot layer is first cured to avoid the quantum dot layer and other structures in the quantum dot film. The tension of each layer in the quantum dot film caused by the solidification of the layers together makes the quantum dot film less prone to wrinkling. Since wrinkles will affect the concentration of quantum dots and the thickness of the quantum dot layer, the absence of quantum dots will form bad spots, and the uneven concentration of quantum dots will cause color une...

Embodiment 1

[0066] The preparation method process of quantum dot film comprises:

[0067] In the first step, the liquid quantum dot colloid is placed in the mold, and after the liquid quantum dot colloid flows stably, the liquid quantum dot colloid is thermally cured to form the quantum dot layer 10, wherein the thermal curing temperature is 150°C, and the thermal curing The time is 15s.

[0068] In the second step, the above-mentioned quantum dot layer is separated from the above-mentioned mold, and the above-mentioned quantum dot layer exposes the opposite first surface and second surface;

[0069] In the third step, the first protective layer 17 is formed on the first surface, the second protective layer 18 is formed on the second surface, and finally the quantum dot film is formed. The specific process is as follows:

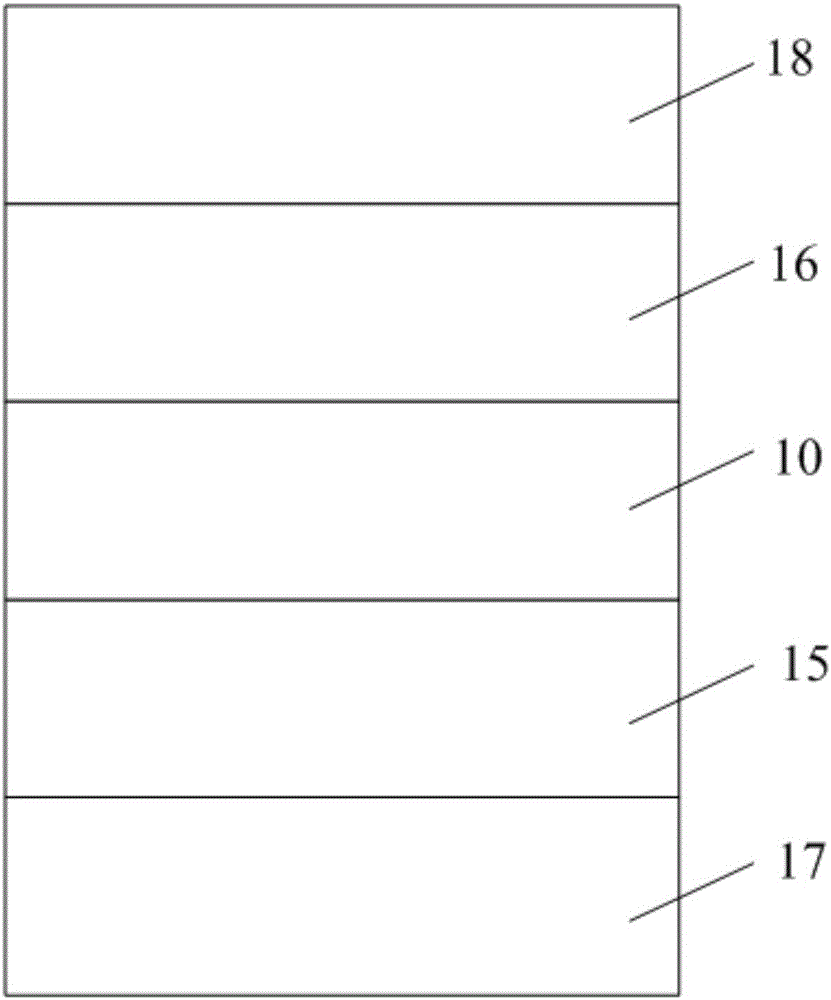

[0070]Specifically, a first adhesive layer 15 is provided on the first surface, a first protective layer 17 is provided on the surface of the first adhesive layer 15 a...

Embodiment 2

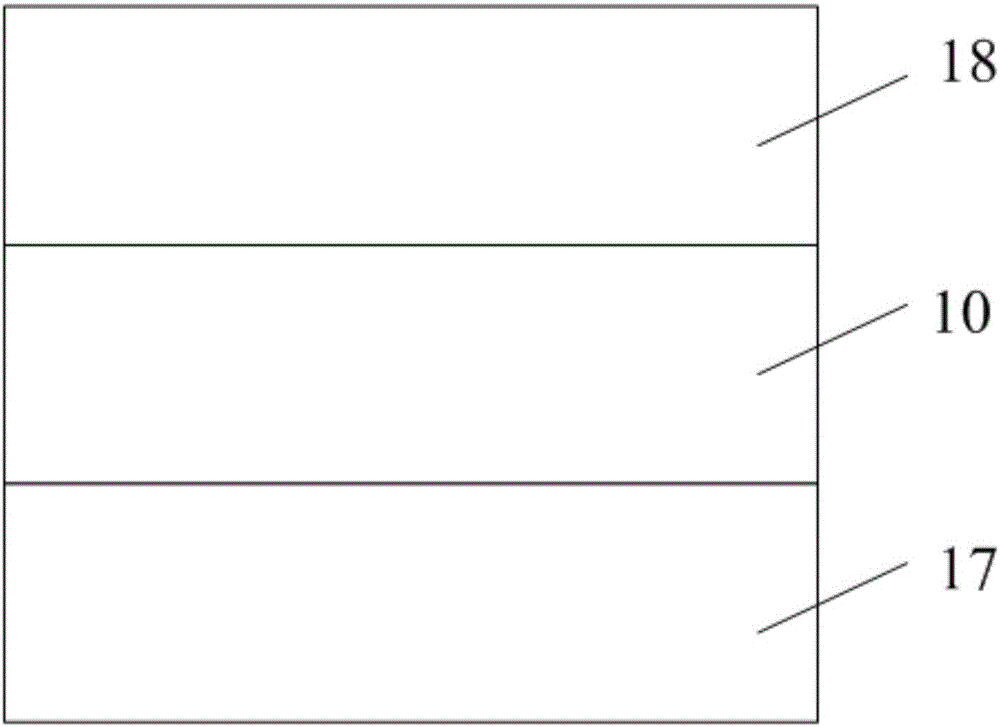

[0073] The difference from Example 1 is that the third step is different. The first protective layer 17 is directly formed on the first surface, and the second protective layer 18 is formed on the second surface. Both the first protective layer 17 and the second protective layer 18 are PVA. layer, the thickness of which is 2 μm, thermally curing the first protective layer 17 and the second protective layer 18 to form figure 2 For the quantum dot film shown, the thermal curing temperature of the first protective layer and the second protective layer is 120° C., and the curing time is 2 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com