Filled modified teflon seal material and its preparation method

A polytetrafluoroethylene and sealing material technology, applied in the field of polymer sealing material modification, can solve the problem that the sealing material effect is not very ideal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] A preparation method for filling a modified polytetrafluoroethylene sealing material, the steps of which are:

[0017] (1) Mixing: Nano-Fe with oleic acid surface modified 3 o 4 Mix with the pretreated polytetrafluoroethylene powder by the above-mentioned mass percentage;

[0018] (2) Molding: Put the uniformly mixed raw materials in a compression mold and press molding, the molding pressure is 50-60MPa, the pressurization speed is 5-10MPa / min, and the pressure is maintained for 15-30min;

[0019] (3) Sintering: heat preservation at 28-30°C for 24 hours, heat up to 300-320°C at a rate of 60-100°C / hour for 0.5-1 hour, and continue to heat up to 370-390°C for 1 hour;

[0020] (4) Cooling: Cool in the furnace to 300-320°C and keep warm for 0.5-1 hour, then cool to room temperature, and store at constant temperature after simple processing and inspection of appearance and size.

[0021] The polytetrafluoroethylene powder in the present invention is a suspended polytetraf...

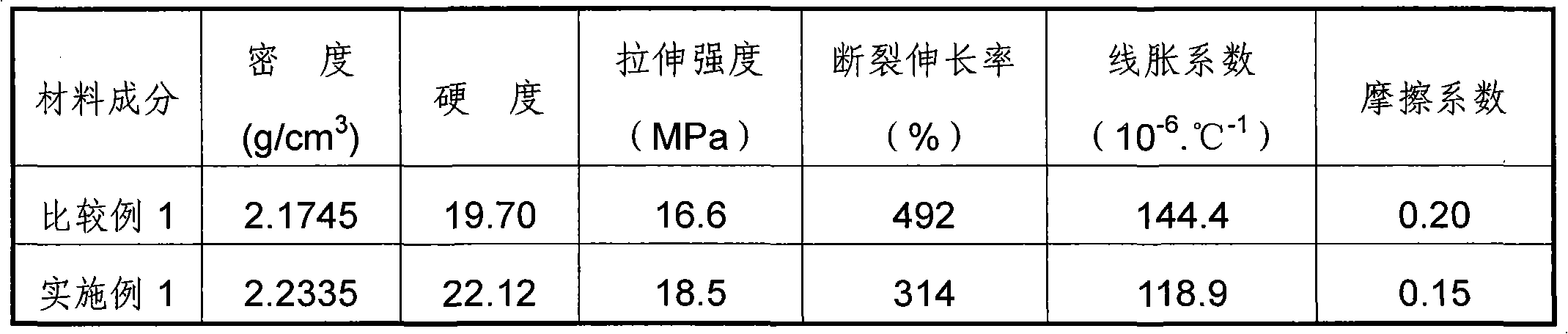

Embodiment 1

[0025] By mass percentage, get 95% polytetrafluoroethylene and 5% oleic acid surface modification nano-Fe 3 o 4 Add to the powder horizontal mixer and stir twice at high speed, each time for 10 minutes; place the uniformly mixed raw materials in the compression mold for molding, the molding pressure is 50MPa, the pressurization speed is 5MPa / min, and the pressure is kept for 15 minutes; keep warm at 28°C For 24 hours, heat up to 320°C at a rate of 100°C / hour for 1 hour, then continue to heat up to 370°C for 1 hour; cool to 320°C with the furnace and hold for 0.5 hours, then cool to room temperature, after simple processing and inspection of appearance dimensions Test material properties.

Embodiment 2

[0031] By mass percentage, get 92% polytetrafluoroethylene and 8% oleic acid surface modification nano-Fe 3 o 4 Add to the powder horizontal mixer and stir at high speed for 2 times, each time for 10 minutes; place the uniformly mixed raw materials in the compression mold for molding, the molding pressure is 55MPa, the pressurization speed is 10MPa / min, and the pressure is kept for 10 minutes; keep warm at 28°C For 24 hours, heat up to 300°C at a rate of 60°C / hour for 0.5 hours and then continue to heat up to 390°C for 1 hour; cool to 300°C with the furnace and hold for 1 hour to obtain a sealing material. The hardness of the material is 23.05, the tensile strength is 18.7MPa, the elongation at break is 286%, and the coefficient of linear expansion is 112.310 -6 .℃ -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Linear expansion coefficient | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com