Lightweight steel-ultrahigh-performance concrete stiffened combination rib plate and construction method thereof

An ultra-high-performance concrete technology, which is applied to bridge parts, erection/assembly bridges, bridges, etc., can solve problems such as the inability to exert the compressive and tensile properties of ultra-high-performance concrete, adverse effects on structural safety, and impact on structural safety. , to achieve the effects of improving crack resistance and overload resistance, increasing stiffness, and improving overall and local stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

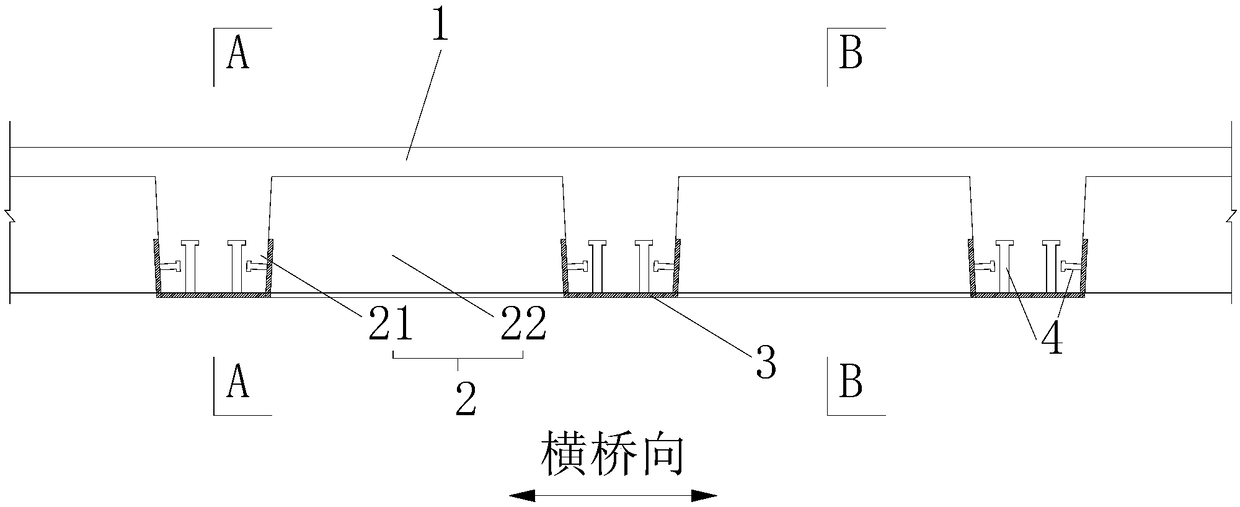

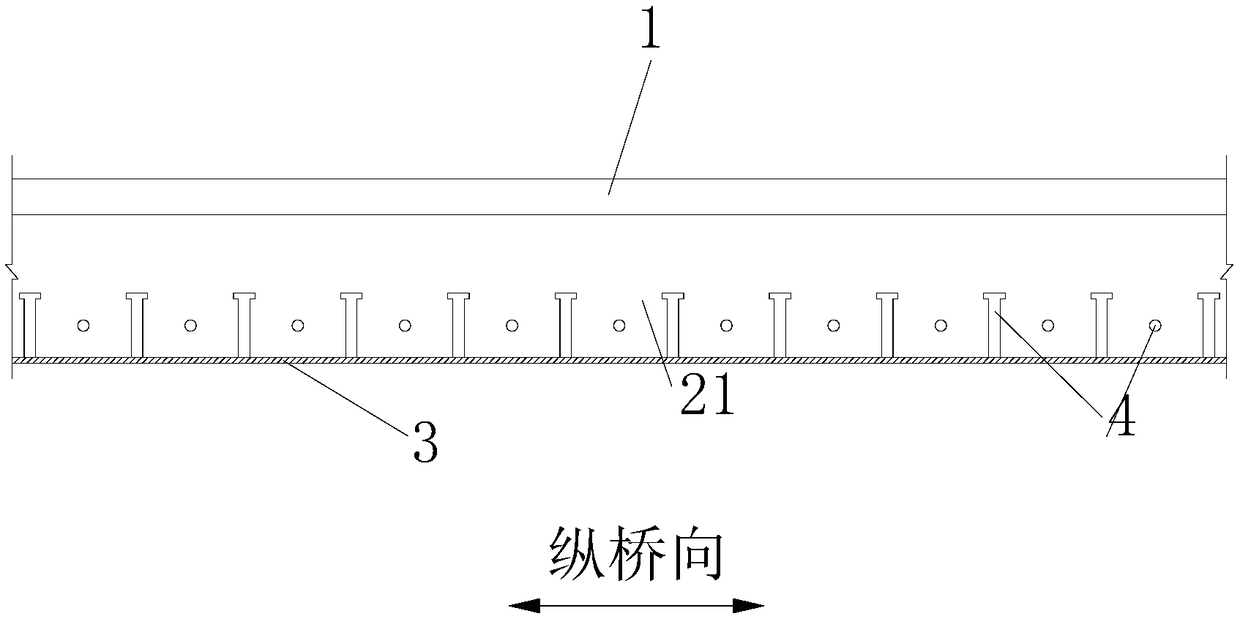

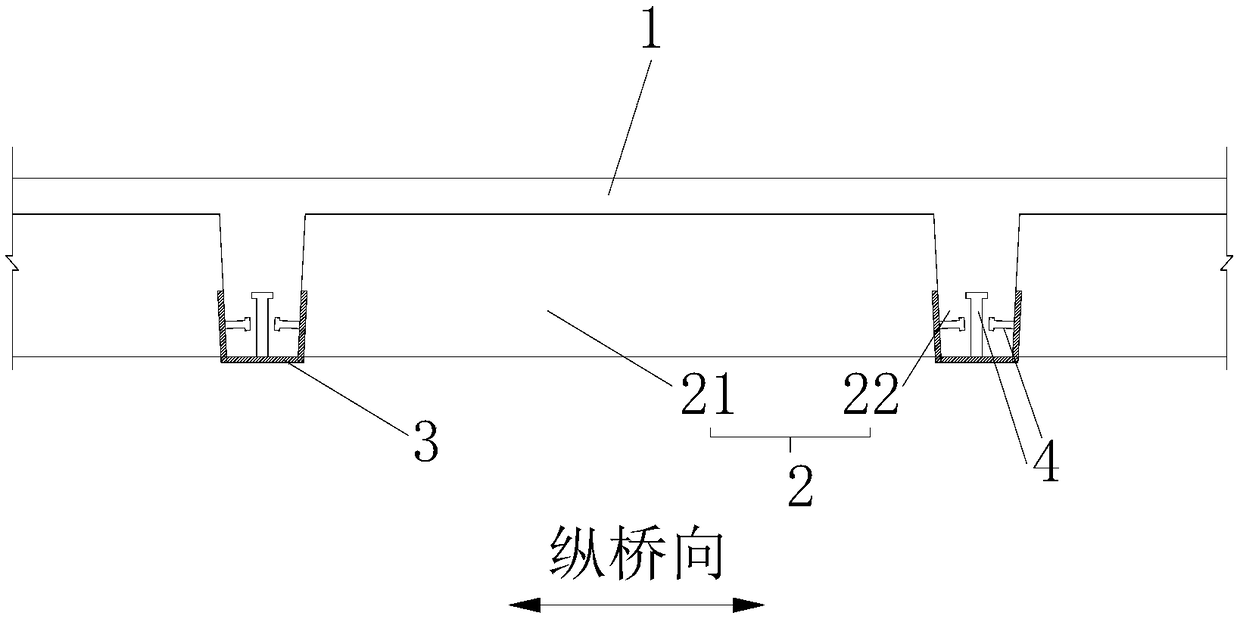

[0047] The light-gauge steel-ultra-high-performance concrete stiff composite rib plate structure of this embodiment includes a panel 1 , a plate rib 2 , a stiffening component 3 , and a shear connector 4 . The plate rib 2 is arranged at the bottom of the panel 1, and is poured into one body with the panel 1 and is perpendicular to the panel 1. The stiffening part 3 is arranged at the bottom of the plate rib 2 and is as wide as the bottom surface of the plate rib 2, and is connected by a shear connector 4 to form a overall.

[0048] Such as Figure 1~3 As shown, in this embodiment, the light-gauge steel-ultra high performance concrete stiff composite rib is the bridge deck in the PK steel box-ultra high performance concrete composite beam. The thickness of the panel 1 is 0.08m, and plate ribs 2 are provided on the bottom of the panel 1 in the longitudinal direction and the transverse direction, which are respectively longitudinal bridge ribs 21 and transverse bridge ribs 22 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com