Low-temperature-resistant asphalt concrete and preparation method thereof

A technology of asphalt concrete and low temperature resistance, applied in the field of concrete, can solve problems such as shortening the service life of roads, affecting road traffic capacity and vehicle driving comfort, and achieves the effects of increasing bonding surface area, improving deformation adaptability, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

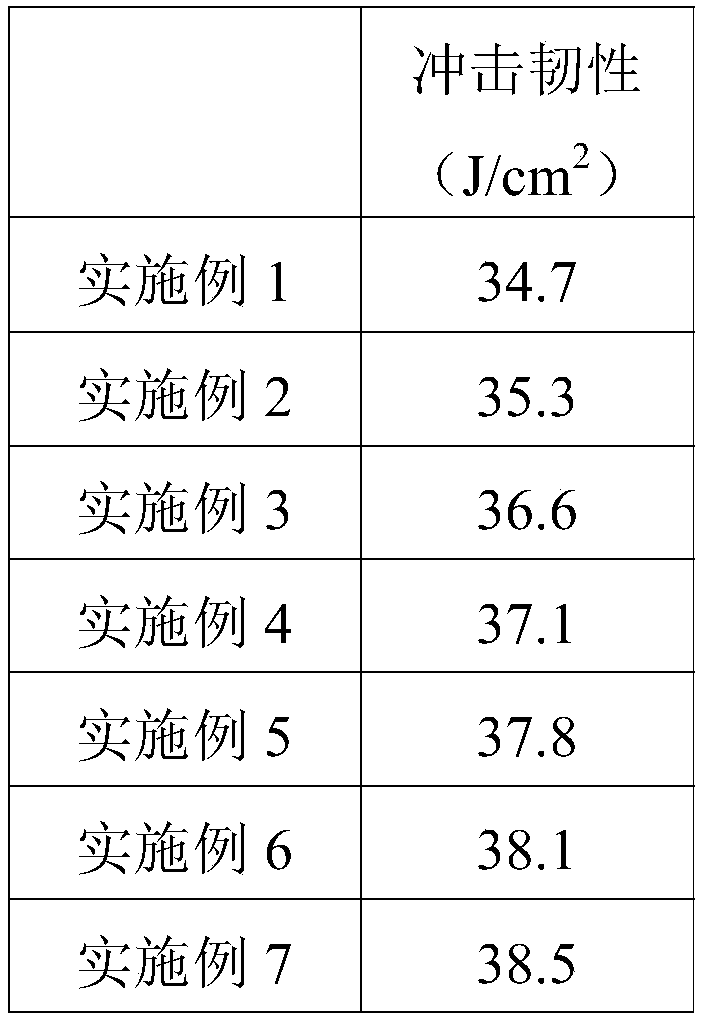

Examples

Embodiment 1

[0049] Low temperature resistant asphalt concrete, prepared from the following raw materials by weight: 400 parts by weight of coarse aggregate, 150 parts by weight of fine aggregate, 40 parts by weight of mineral powder, 30 parts by weight of matrix asphalt, 20 parts by weight of diatomaceous earth, glass fiber 2 parts by weight.

[0050] The preparation method of low temperature resistant asphalt concrete comprises the following steps:

[0051] Step 1: Insulate base asphalt and diatomite at 130°C for 6 hours respectively; add the insulated diatomite into the insulated base asphalt, and simultaneously use a high-speed shear mixer to shear at 550 rpm for 10 Minutes, keep the asphalt temperature at 130°C during the shearing process, so that the diatomite is evenly dispersed in the asphalt mortar to obtain diatomite-modified asphalt, which is kept at 160°C for later use;

[0052] Step 2: Insulate the coarse aggregate and fine aggregate at 160°C for 2 hours respectively; mix the...

Embodiment 2

[0055] Low temperature resistant asphalt concrete is prepared from the following raw materials by weight: 400 parts by weight of coarse aggregate, 150 parts by weight of fine aggregate, 40 parts by weight of mineral powder, 30 parts by weight of base asphalt, 20 parts by weight of diatomaceous earth, coupled Agent treatment glass fiber 2 parts by weight.

[0056] The preparation process of the glass fiber treated with the coupling agent is as follows: configure a coupling agent aqueous solution with a mass fraction of 2% of the coupling agent KH550; dry the glass fiber at 120°C for 2 hours, add it to a high-speed stirrer, and then add the coupling agent The glass fiber accounts for 30% of the mass of the coupling agent aqueous solution. After stirring at 300 rpm for 2 minutes, it is dried at 120° C. for 2 hours to obtain the glass fiber treated with the coupling agent.

[0057] The preparation method of low temperature resistant asphalt concrete comprises the following steps: ...

Embodiment 3

[0062] Low temperature resistant asphalt concrete is prepared from the following raw materials by weight: 400 parts by weight of coarse aggregate, 150 parts by weight of fine aggregate, 40 parts by weight of mineral powder, 30 parts by weight of base asphalt, 20 parts by weight of diatomaceous earth, coupled Agent treatment glass fiber 2 parts by weight.

[0063] The preparation process of described coupling agent processing glass fiber is:

[0064] (1) Preparation of sizing agent: Add 1.5 g of tetraethyl orthosilicate to 10 g of water-based epoxy resin curing agent and stir for 30 minutes at 100 rpm; then add 0.3 g of coupling agent KH550 and stir at 100 rpm 10 minutes; Finally, add 10 g of water-based epoxy resin dropwise at a speed of 0.3 g / min, and stir for 30 minutes at 100 rpm; after the stirring is completed, add deionized water to dilute 100 times according to the mass to obtain the sizing agent;

[0065] (2) Glass fiber coupling agent treatment: heat-treat the glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com