Grooved steel-concrete combination beam

A technology of reinforced concrete and composite beams, applied in bridges, buildings, etc., can solve problems such as complicated construction techniques, difficulties in the application of channel beams, and reduced durability, so as to avoid steel bar binding, simple support and connection structure, and high durability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

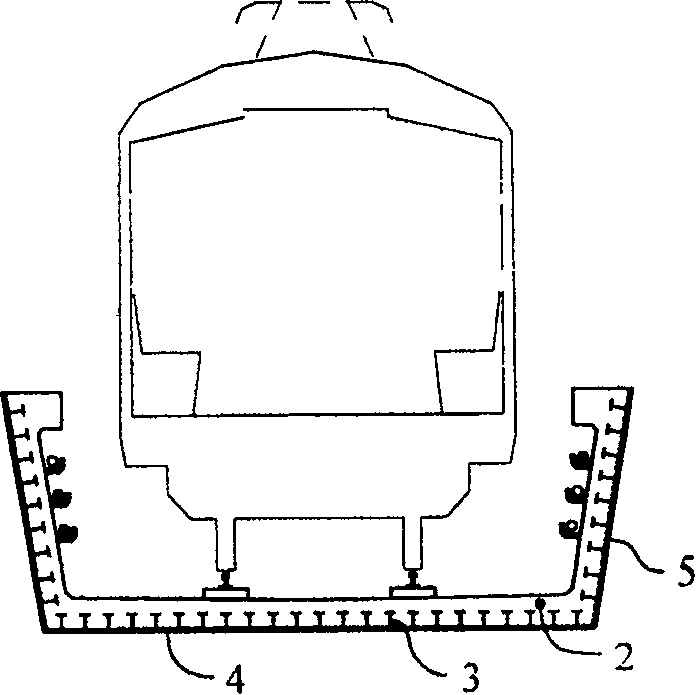

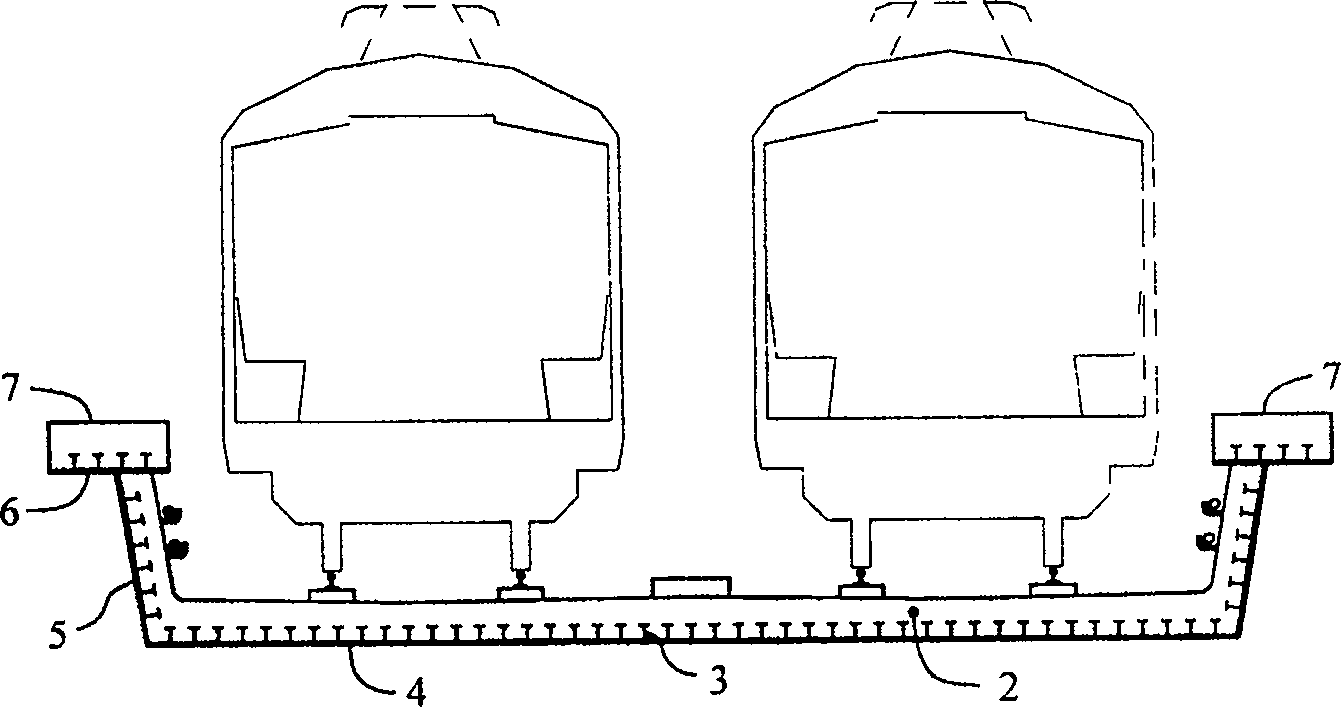

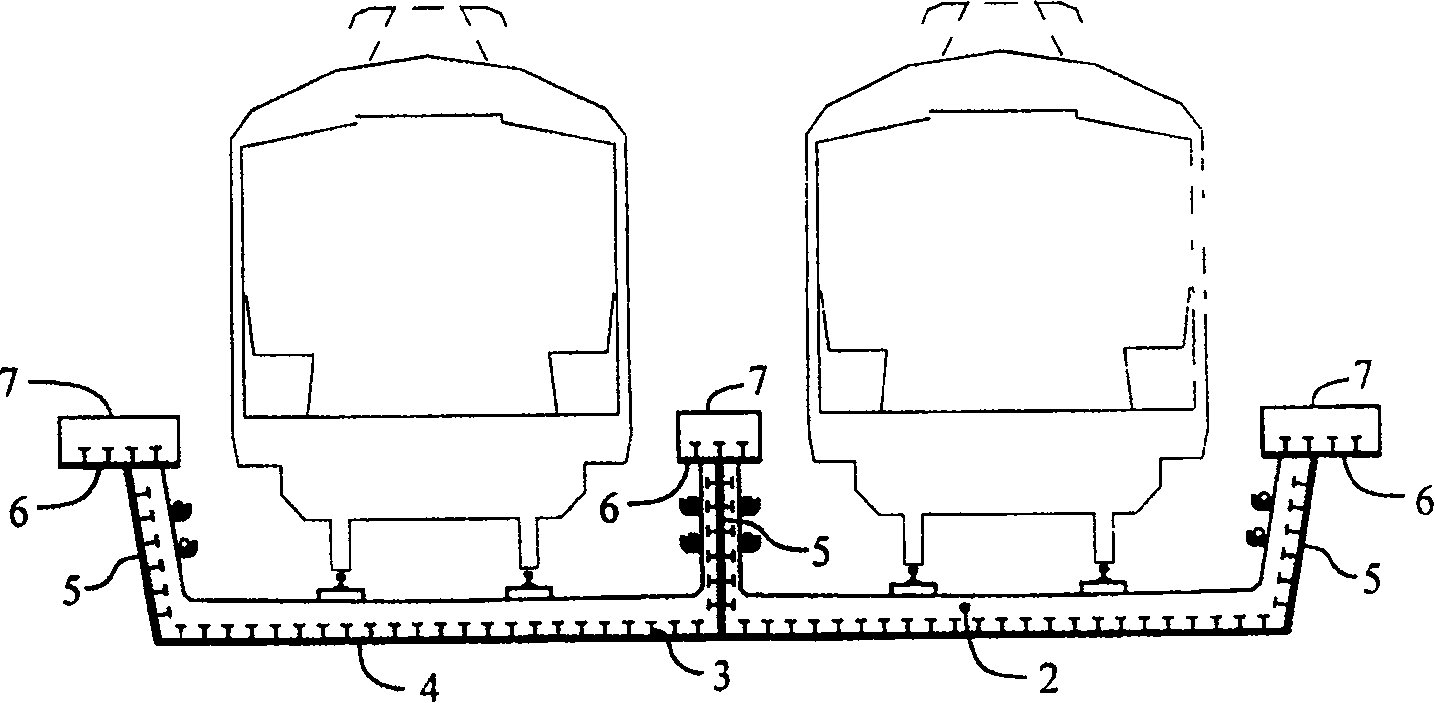

[0012] The invention provides a channel-shaped steel beam-concrete composite beam that can significantly improve structural bearing capacity, rigidity, crack resistance and construction performance. exist figure 1 , figure 2 with image 3 In the structural schematic diagram of the channel steel beam-concrete composite beam shown, the shear connector 3 is fusion-welded on the prefabricated upper open steel box girder. Concrete 2 is poured on the inner side of the steel box girder and integrated with the steel box girder. Concrete 2 is equipped with a certain number of stressed steel bars and structural steel bars.

[0013] Construction procedure of the present invention is:

[0014] The channel-shaped steel beam-concrete composite beam of the present invention is composed of steel structure and post-cast concrete. The two parts are comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com