Patents

Literature

46results about How to "Easy to install in place" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

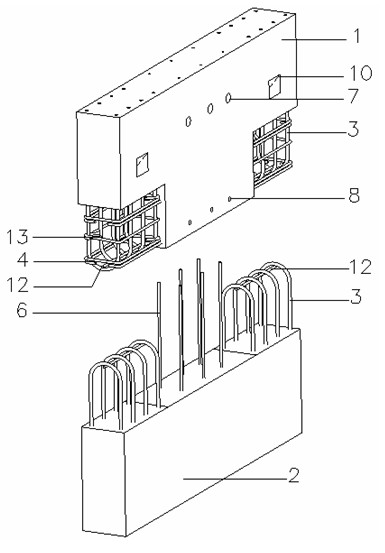

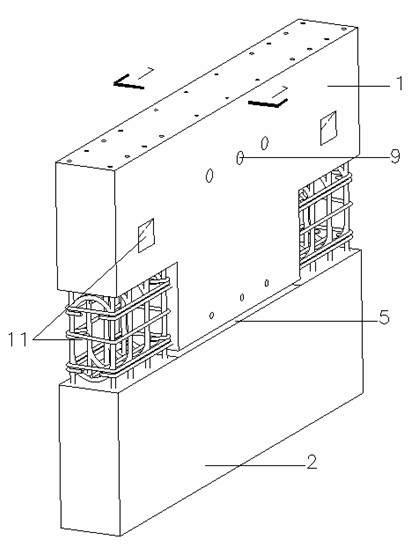

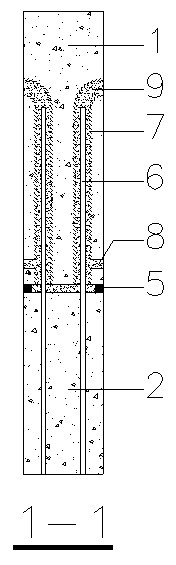

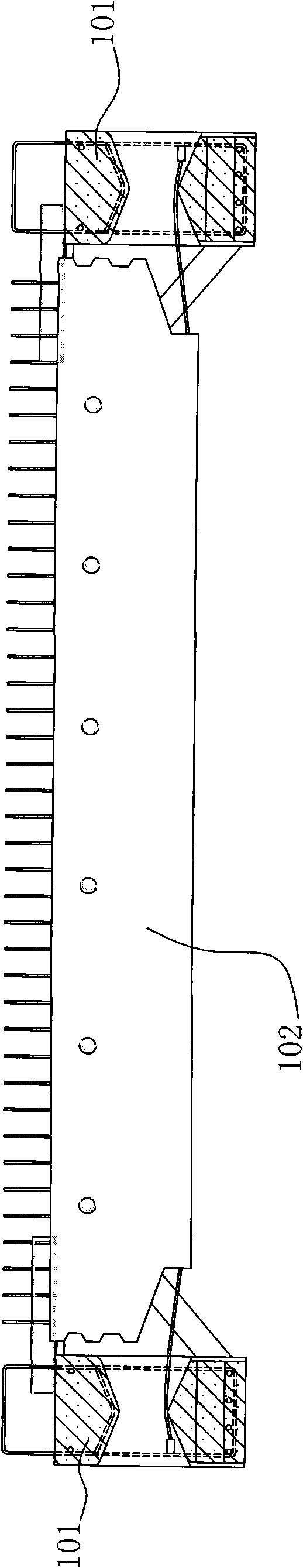

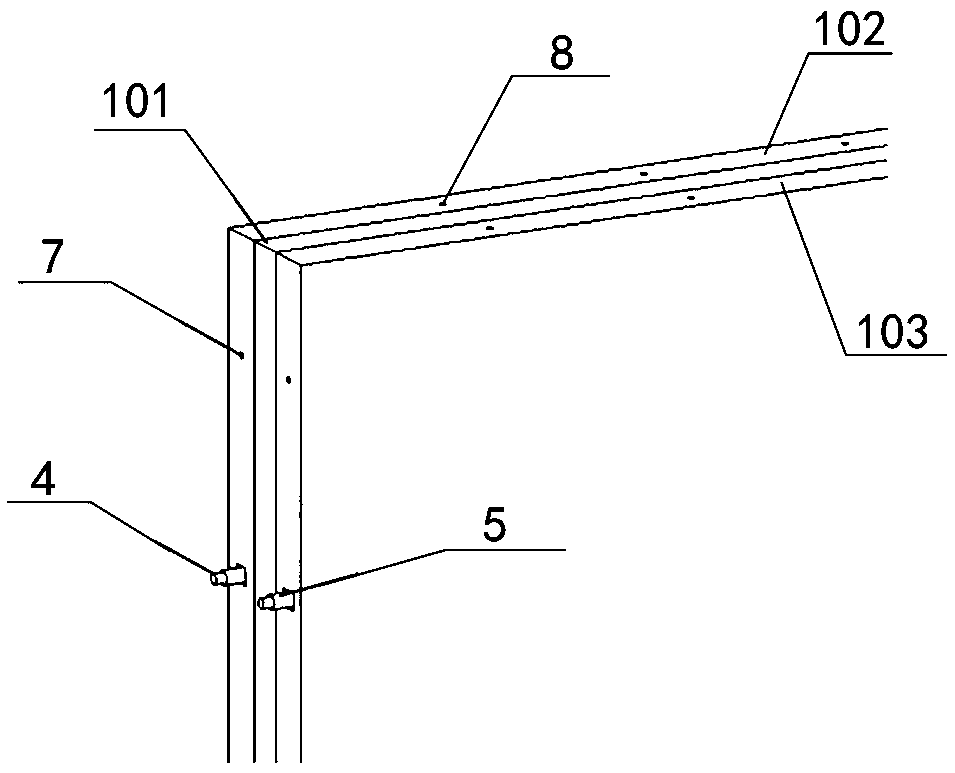

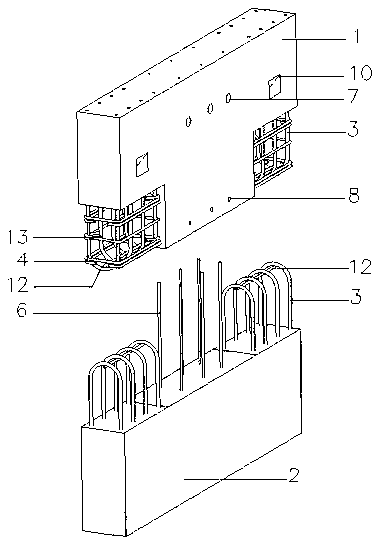

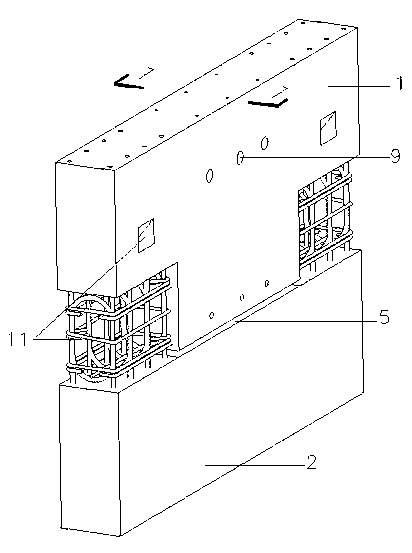

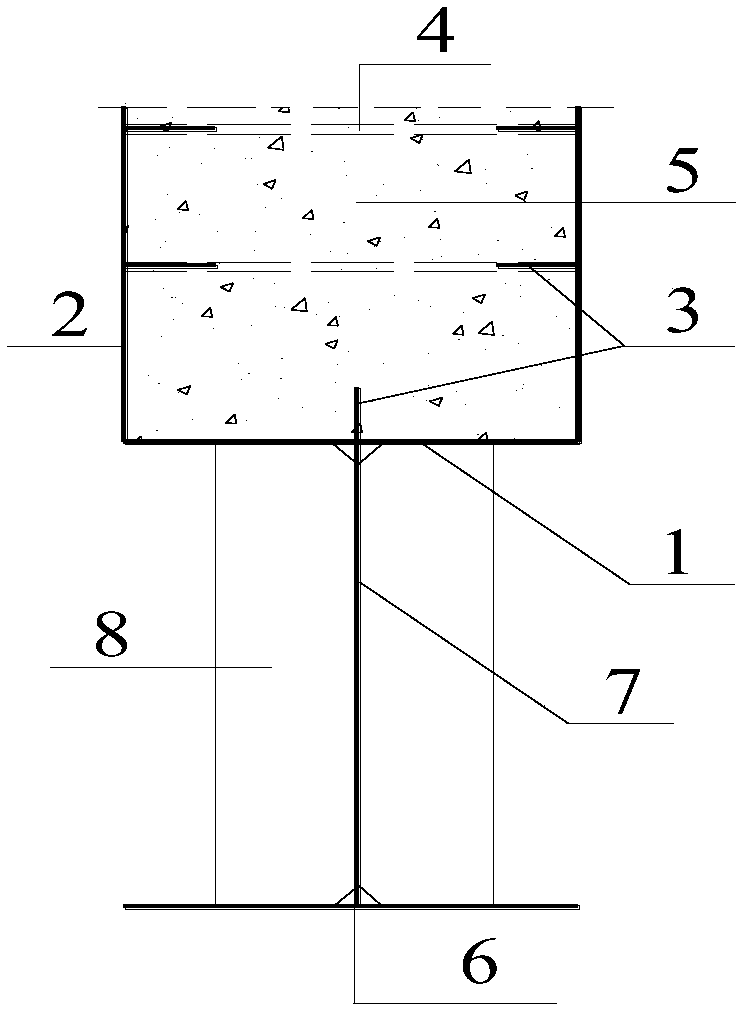

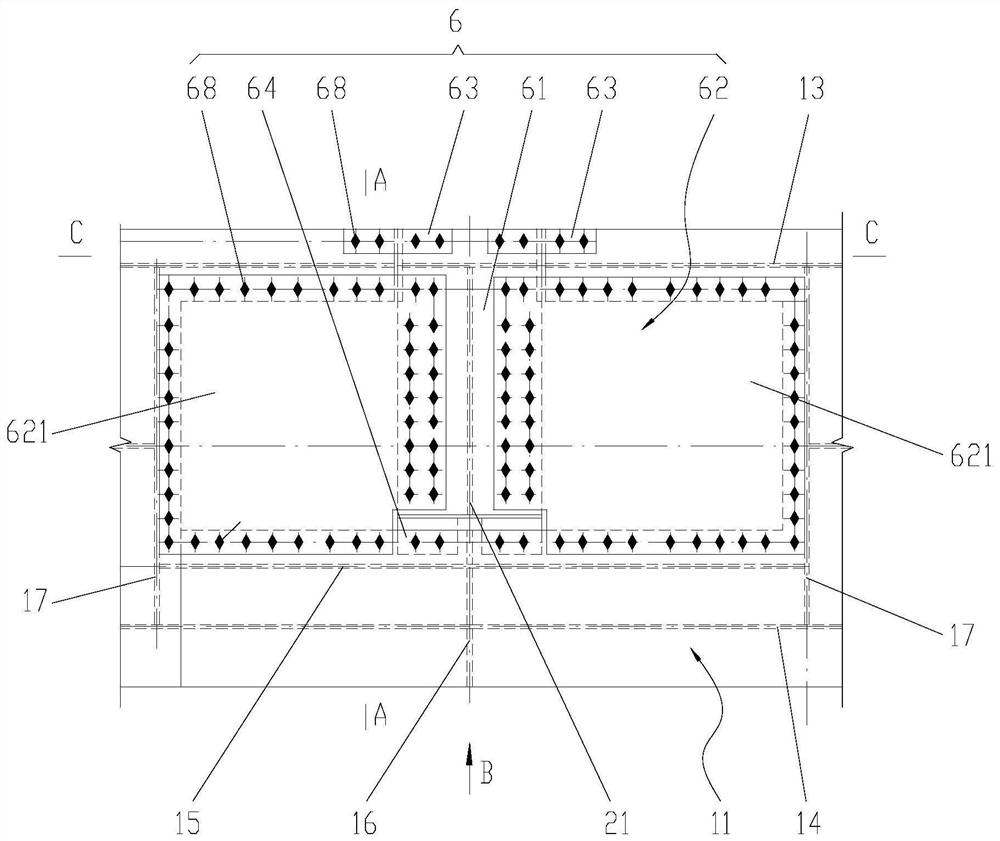

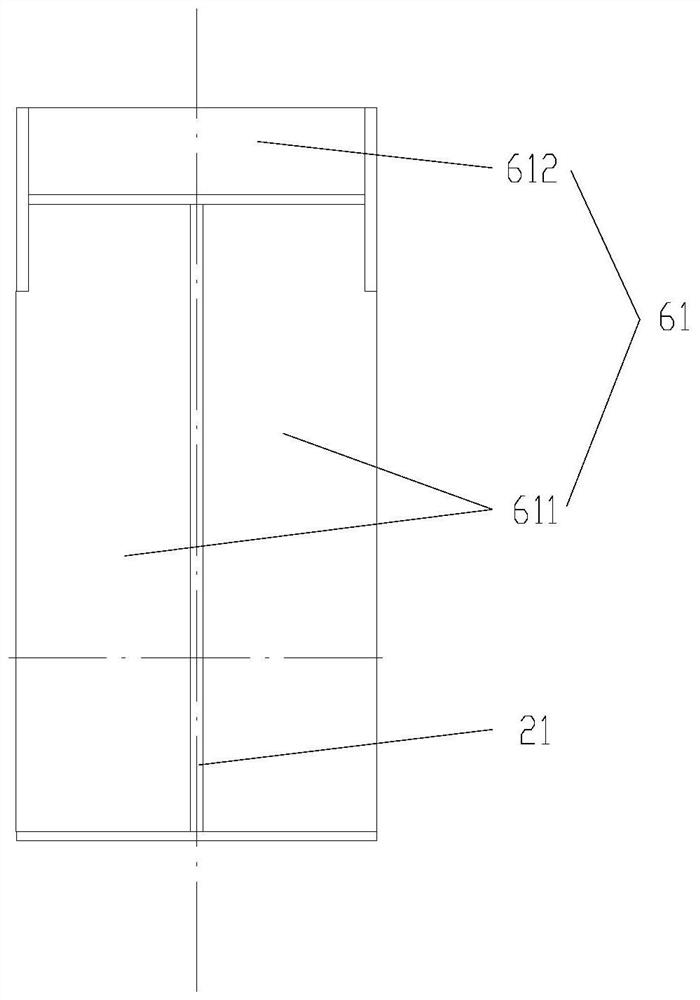

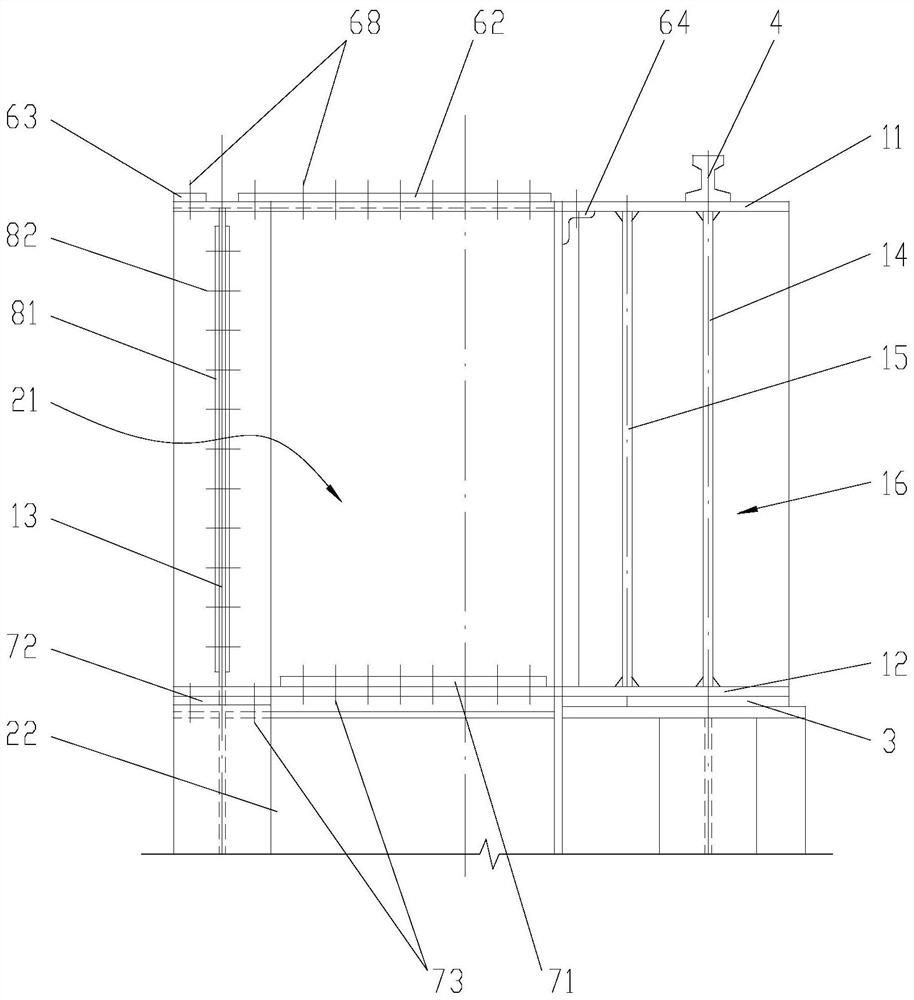

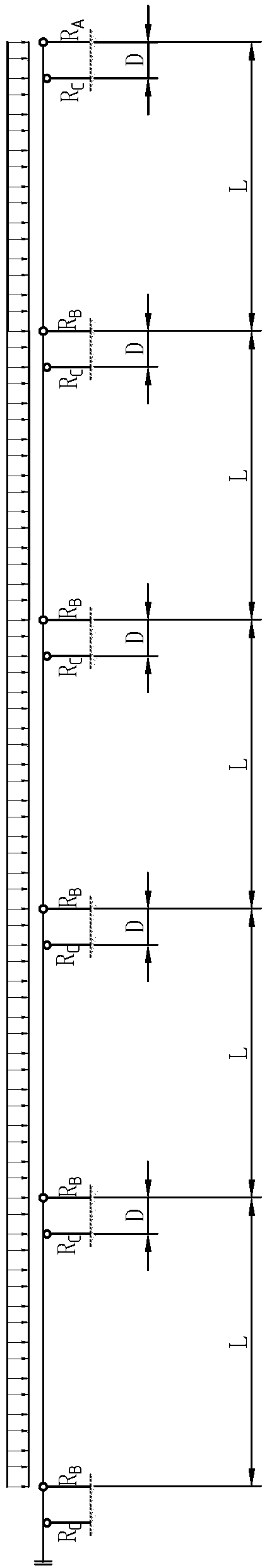

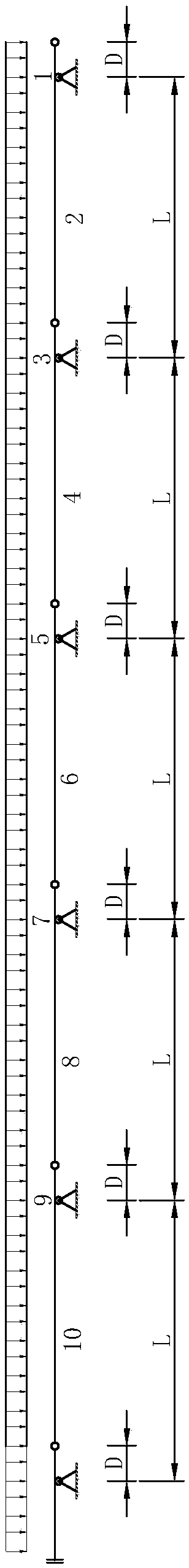

Vertical mixed connection structure and method of prefabricated internal wallboards for assembling shear wall structure

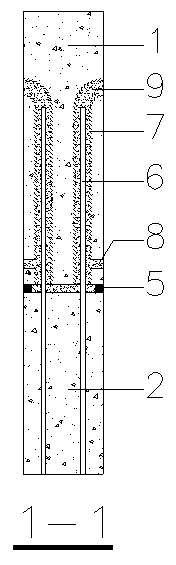

The invention discloses a vertical mixed connection structure and method of prefabricated internal wallboards for assembling a shear wall structure. On the structure, edge components of upper-layer and lower-layer prefabricated internal wallboard structures are overlapped through vertical steel bars and U-shaped ribs, and horizontal reinforcing ribs and local cast-in-place concrete are arranged in a closed ring so as to realize the edge components equivalent to the cast-in-place concrete, the vertically distributed steel bars at the middle part of the components are connected in a manner of indirect overlapping by use of mortar anchor steel bars of a retention metal mortar anchor pipe so as to form an entire shear wall. By utilizing the local cast-in-place concrete moist joint at the edgecomponent part formed by the mixed connection and the dry joint of bedding and grouting at the part of the vertically distributed steel bars, the shear strength and rigidity of the horizontal jointing part of the prefabricated internal wallboards are improved; casting holes reserved at the bottom of the edge components can be used for solving the problem of casting the local cast-in-place concrete; and the vertically distributed steel bars are connected in a manner of indirect overlapping by use of the mortar anchor, which facilitates the installation and temporary fixation of the wallboards on a concrete floor. The mixed connection structure of the prefabricated internal wallboards, provided by the invention, ensures the overall performance of the shear wall; and construction is convenient.

Owner:SOUTHEAST UNIV

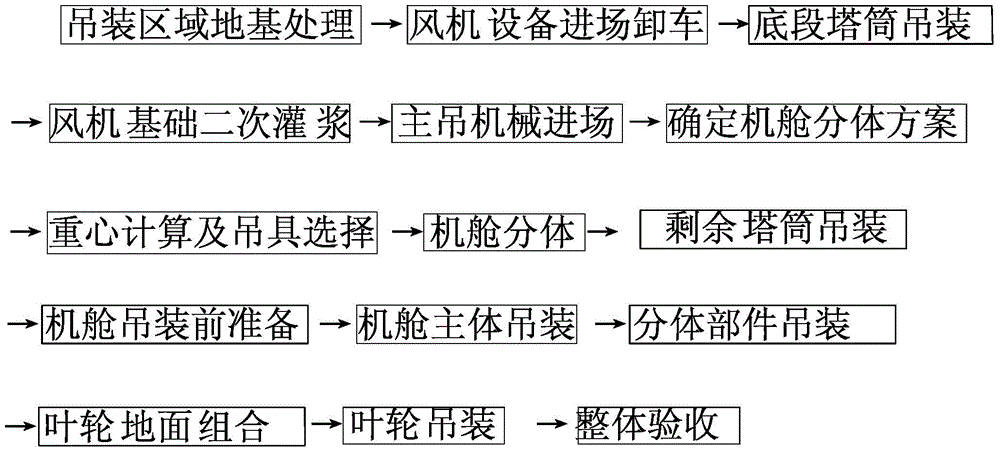

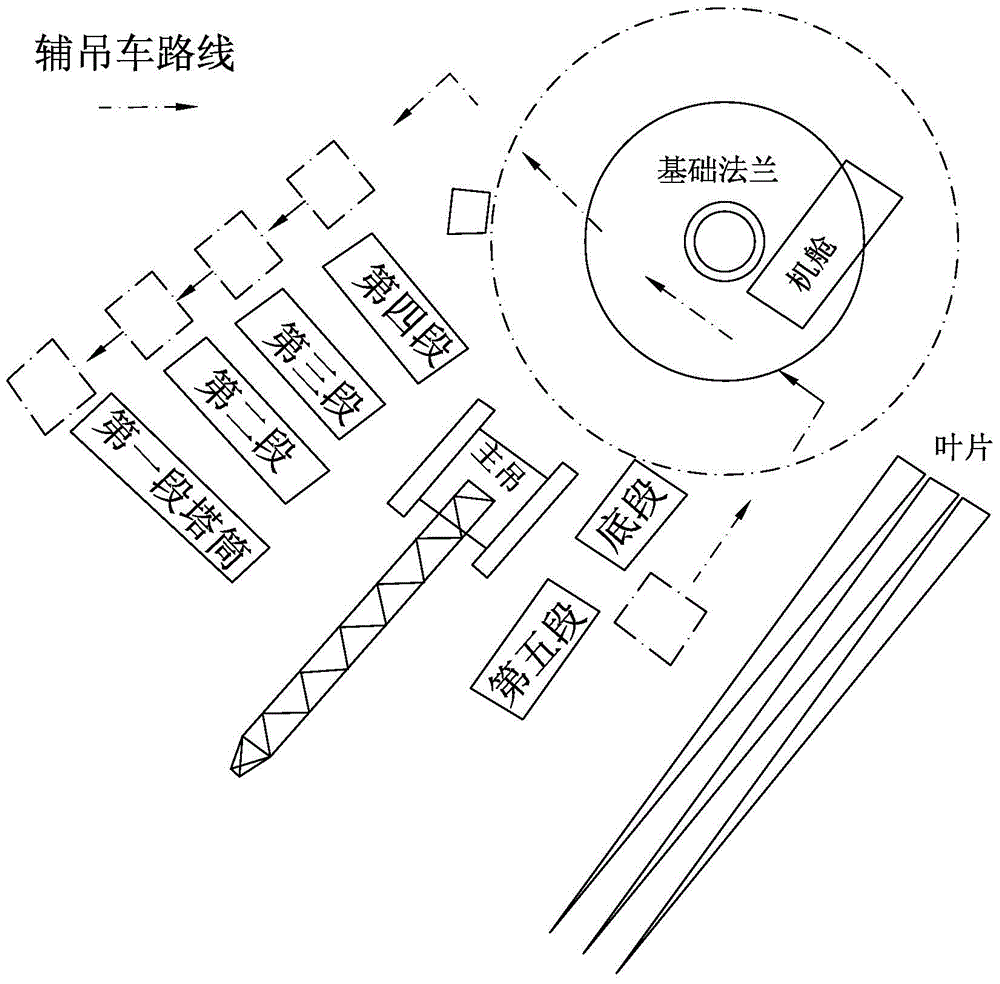

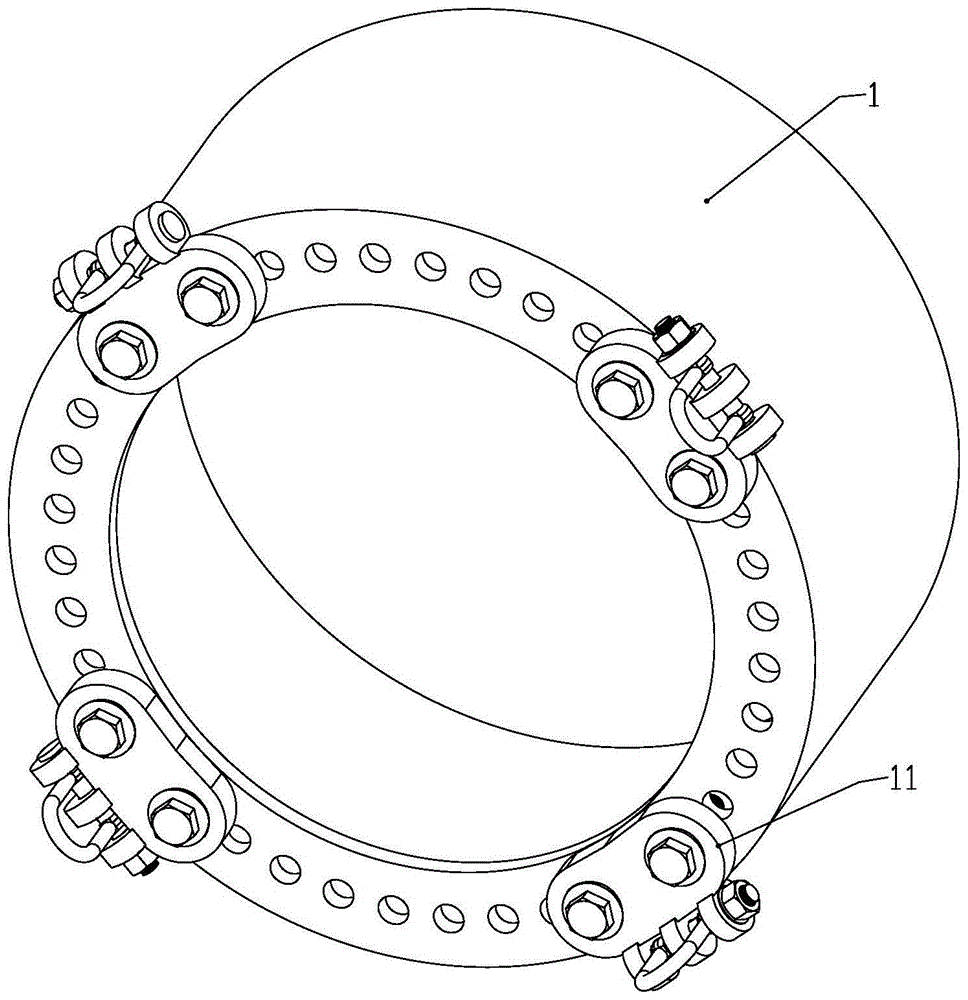

Split type hoisting method for 5MW land type wind generating set

ActiveCN105000462AReduce single lifting weightReduced mechanical lifting performance requirementsLoad-engaging elementsGravity centerEngineering

The invention discloses a split type hoisting method for a 5MW land type wind generating set. According to the method, a cabin is hoisted in a split mode, and split into a cabin body, a generator, a maintenance crane and a top housing according to the weight and the boundary dimension of all parts of the cabin and the hoisting capacity of a main hoisting machine; after the cabin is split, software is utilized for analyzing and recalculating the gravity center position to adjust the design of a hoisting sling, and therefore the level and the safety of cabin hoisting are ensured. The main hoisting machine is utilized for sequentially installing the cabin body and the generator in place and sequentially installing the maintenance crane and the top housing in place. According to a general scheme, a 1600t crawler crane is needed when a whole hoisting scheme is adopted for a 5MW fan, while by means of the implementation of the method, the construction requirement can be met by adopting a 1000t crawler crane, and therefore the construction cost is effectively saved.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

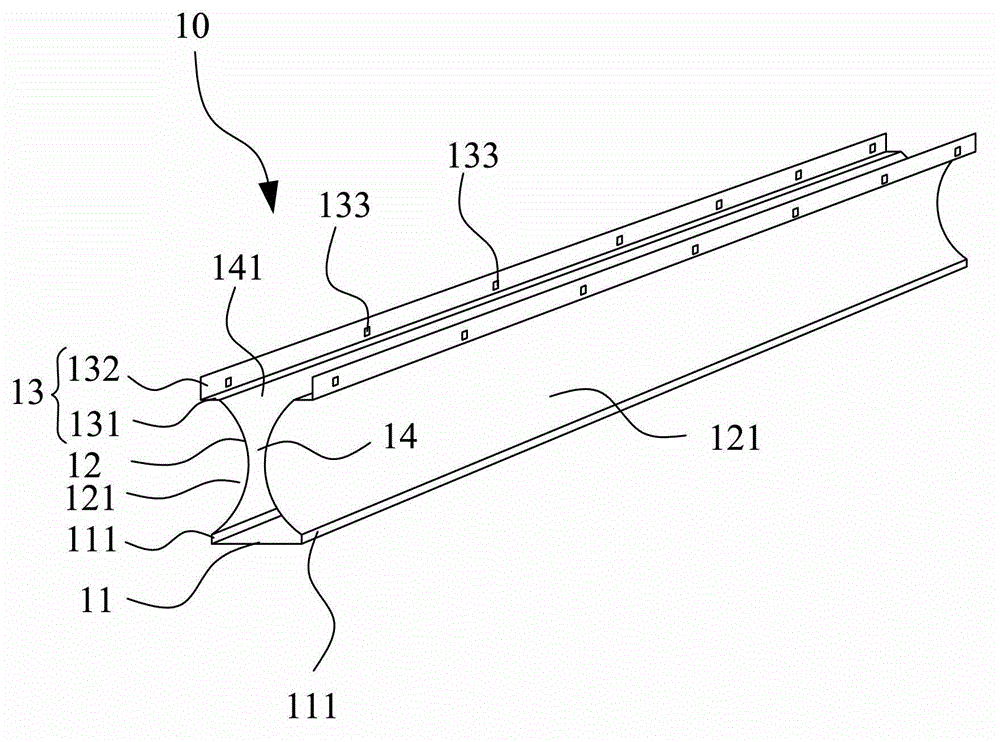

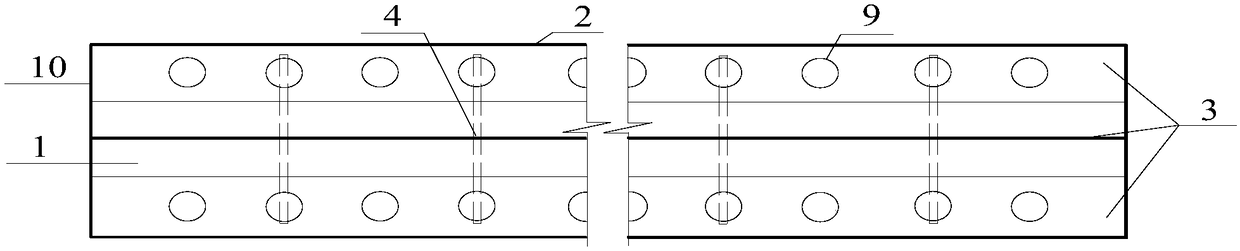

Novel reinforced concrete prefabricated integrally-cast building structure system and construction method thereof

ActiveCN102418386AReduce steel consumptionReduce the overall heightFloorsBuilding material handlingReinforced concreteFloor slab

The invention relates to a novel reinforced concrete prefabricated integrally-cast building structure system, which comprises a floor slab, superposed beams and columns and / or shearing walls. Each superposed beam comprises a primary beam and a secondary beam and consists of a prestressed prefabricated beam and a cast-in-situ part. The prestressed prefabricated beam comprises a beam body and prestressed steel stranded wires. Section steel is arranged at the end parts of the beam body. One part of the section steel is buried in the beam body and the other part of the section steel is exposed at the end part of the beam body. The prefabricated beam in the primary beam is connected with the columns and / or the shearing walls through the section steel. The prefabricated beam in the secondary beam is placed on the primary beam through the section steels. A plurality of template supporting holes are longitudinally arranged on the beam body of the prefabricated beam of the secondary beam and the beam body of the prefabricated beam of the primary beam in parallel with the secondary beam. By adopting the prefabricated beams to be integrally cast with the cast-in-situ beams and the cast-in-situ floor slab to form a structure system, the prefabricated beams are fabricated by adopting a pre-tensioning prestressed technique and can be produced on a large scale in plants at one time and the production cost is reduced.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

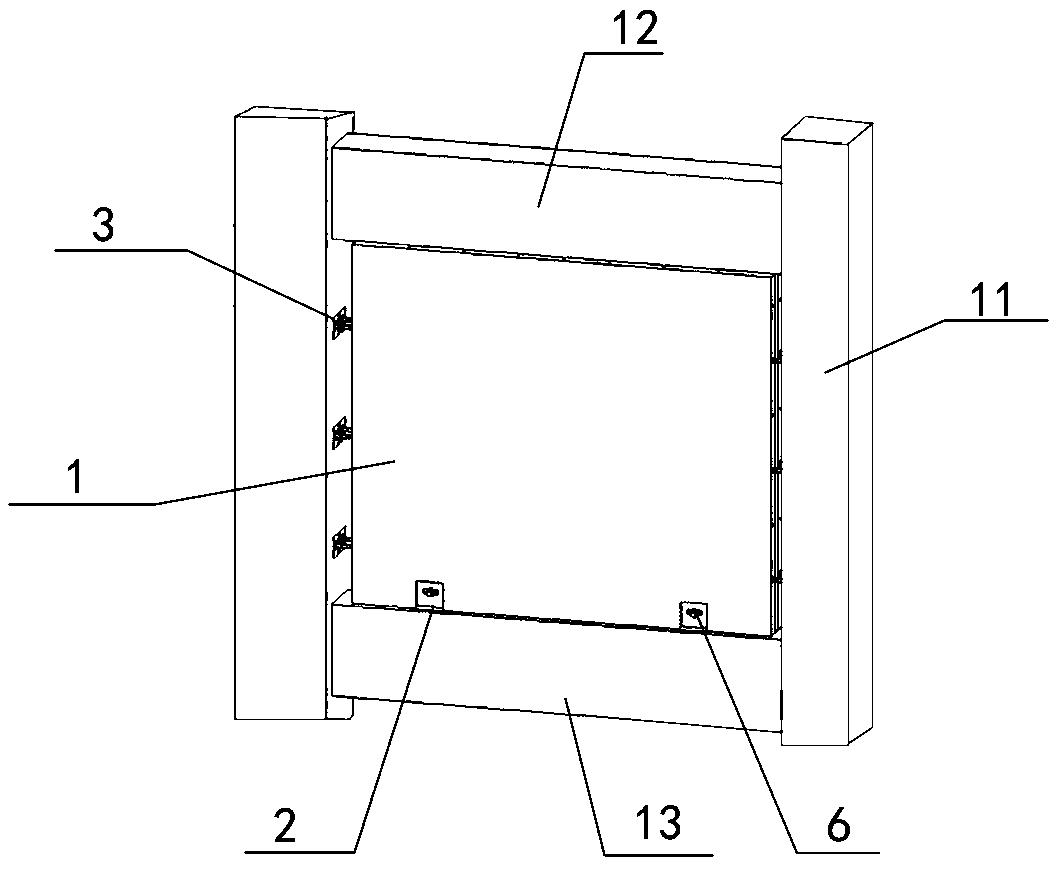

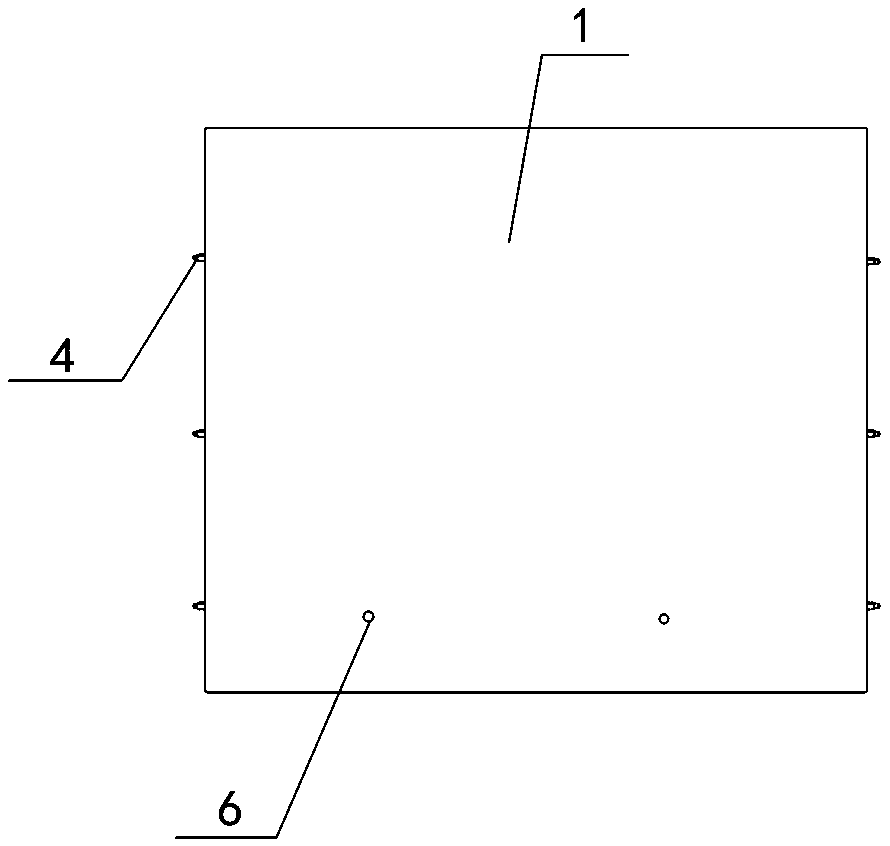

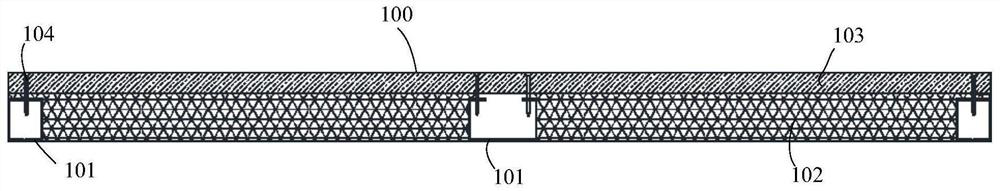

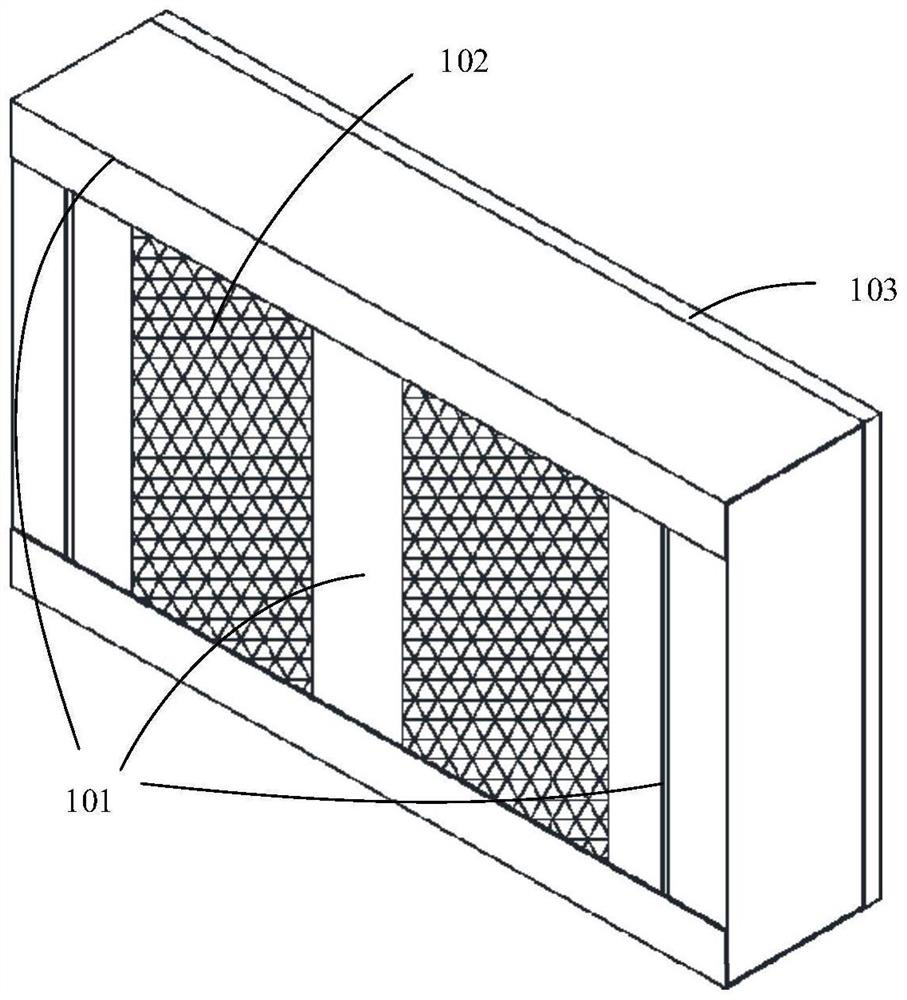

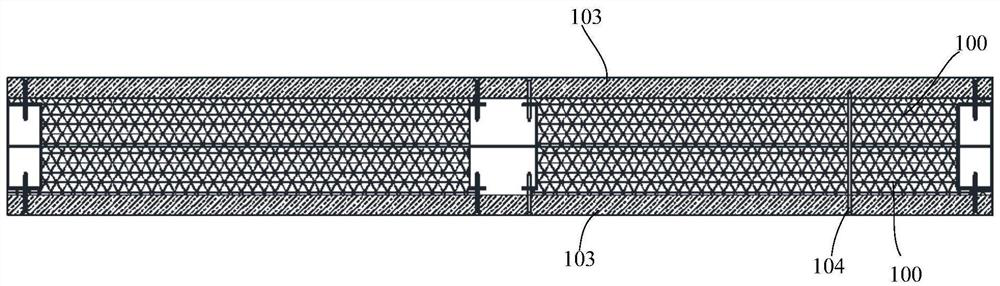

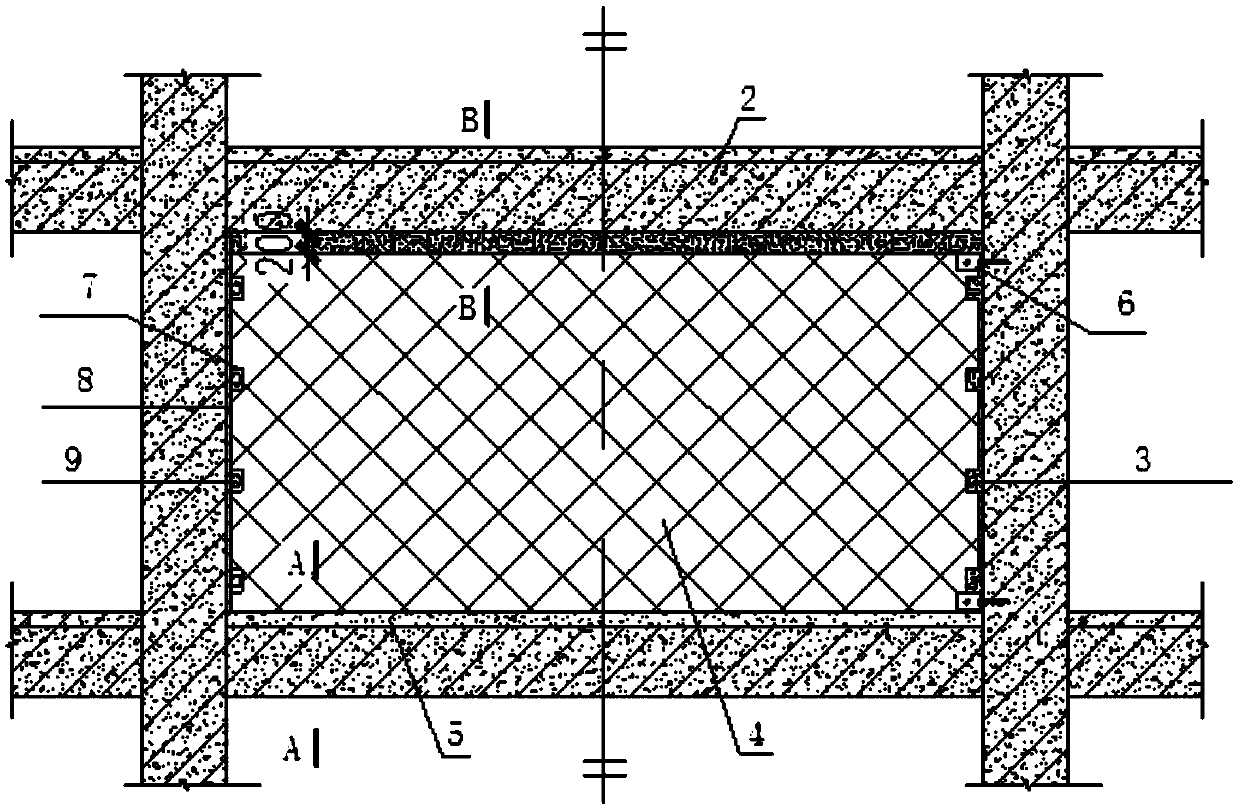

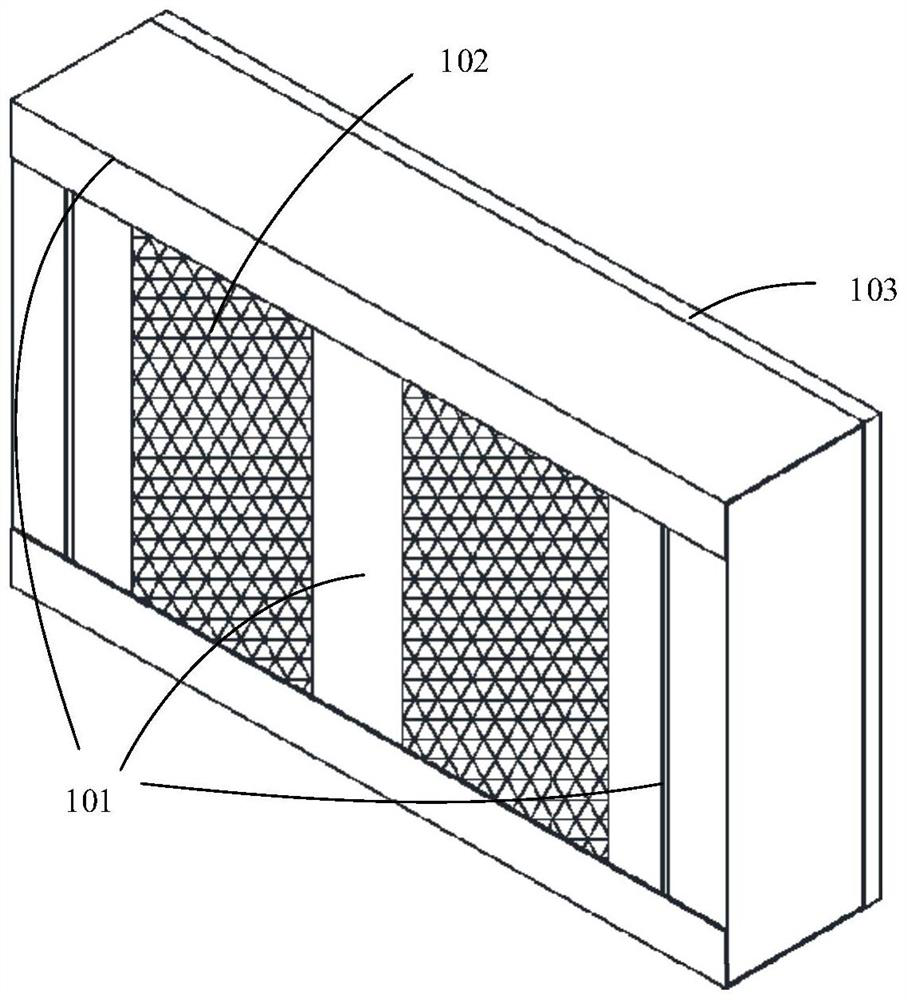

Assembly type concrete frame filling wall structure system and construction method thereof

ActiveCN109024993AAvoid cracking or even breakingGuaranteed co-morphingWallsProtective buildings/sheltersRebarStructure system

The invention discloses an assembly type concrete frame filling wall structure system. The system comprises a concrete frame and a prefabricated filling wallboard, the concrete frame is rectangular and comprises frame columns, an upper frame beam and a lower frame beam, and angle steel connecting pieces are welded to the top of the lower frame beam; box connecting pieces are pre-buried at the inner sides of the frame columns at intervals, and the box connecting pieces comprise cuboid shells and connecting screw rods. The two ends of each main transverse construction steel bar in the prefabricated filling wallboard extend out of the two sides of the prefabricated filling wallboard, and the two ends of each main transverse construction steel bar are each connected with one end of a straightthreaded sleeve; the other end of each straight thread sleeve is connected with a connecting screw rod, and then the prefabricated filling wallboard is connected between the frame columns. Bolts are pre-buried at the bottom of the prefabricated filling wallboard, one end of each bolt penetrates through the corresponding angle steel connecting piece, and then the bottom of the prefabricated fillingwallboard is connected with the lower frame beam.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

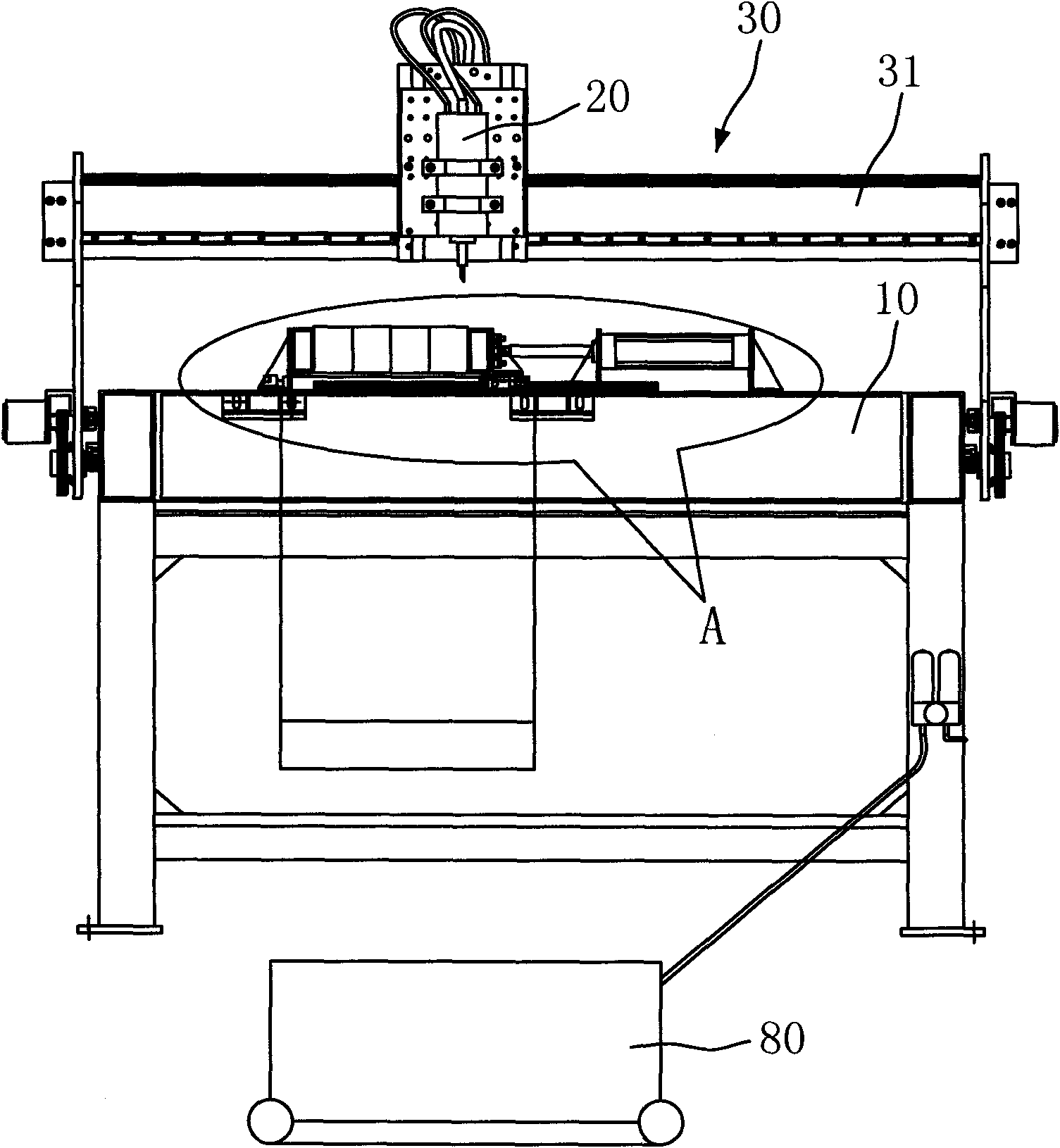

Workpiece clamping device for engraving machine

InactiveCN101863187AEasy to install in placeEffectively fixedEngravingEngineeringMechanical engineering

The invention belongs to the technical field of engraving machines, in particular to a workpiece clamping device for an engraving machine, comprising a work table and a processing head which is mounted at the upper side of the work table. Two sides of a workpiece are provided with a first clamping plate and a second clamping plate for fixing the workpiece in place; and the clamp plates are arranged on the work table. According to the technical scheme, as the workpiece clamping system comprises the first clamping plate and the second clamping plate, the workpiece clamping device can effectively fix cylindrical or long strip-shaped sectional materials, is convenient to mount the workpiece in place, and can process various workpieces with different widths. Therefore, the workpiece clamping device for an engraving machine has simple structure and good clamping and fixing effect.

Owner:HEFEI SIWEI CNC MACHINERY

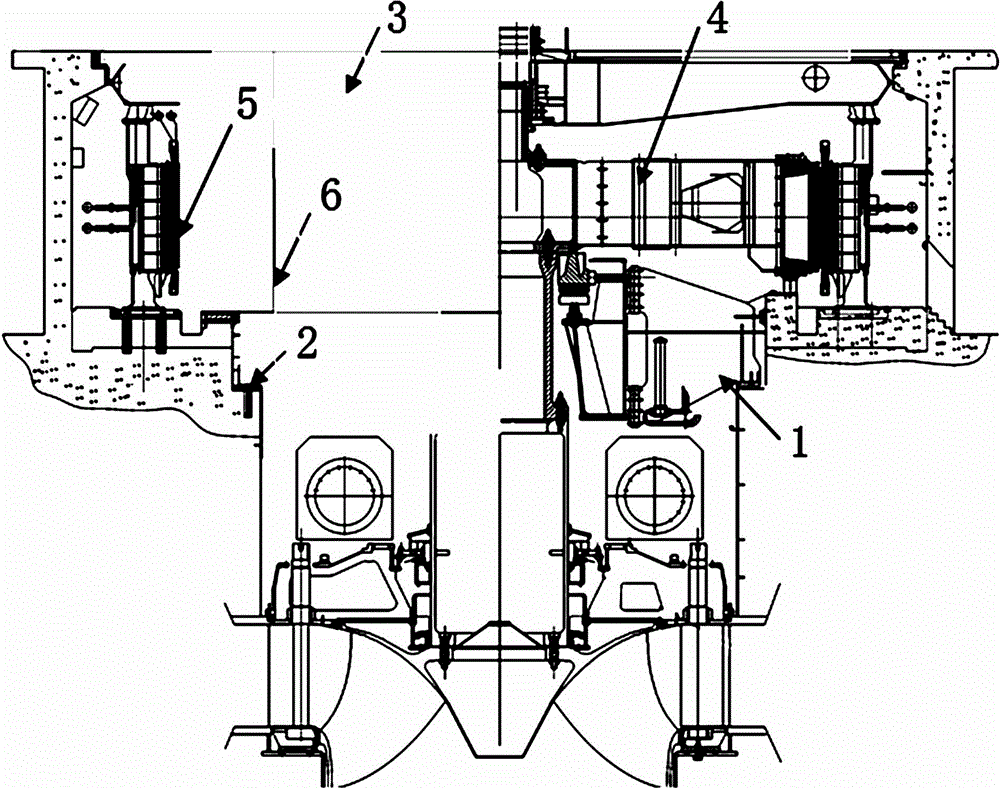

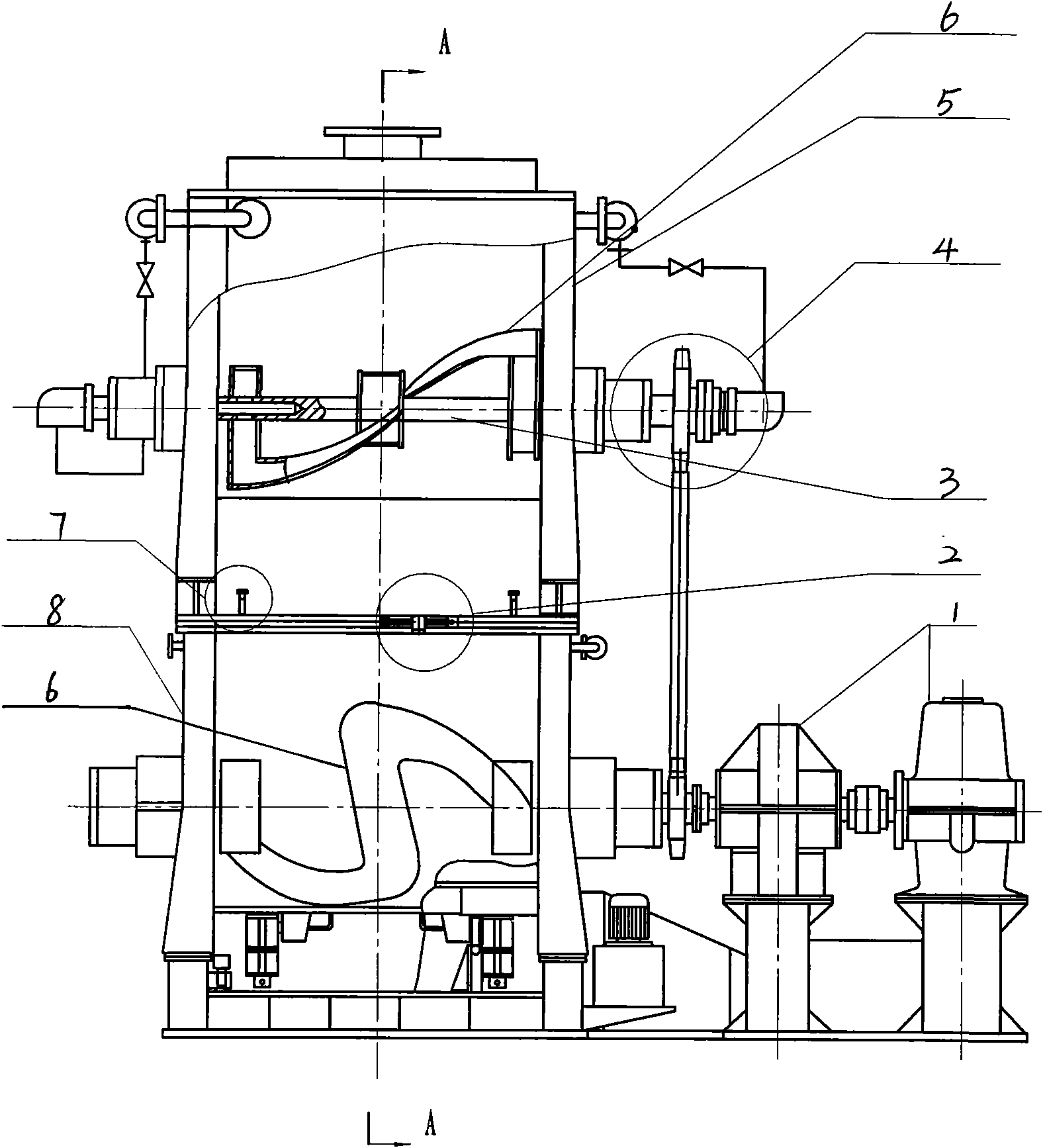

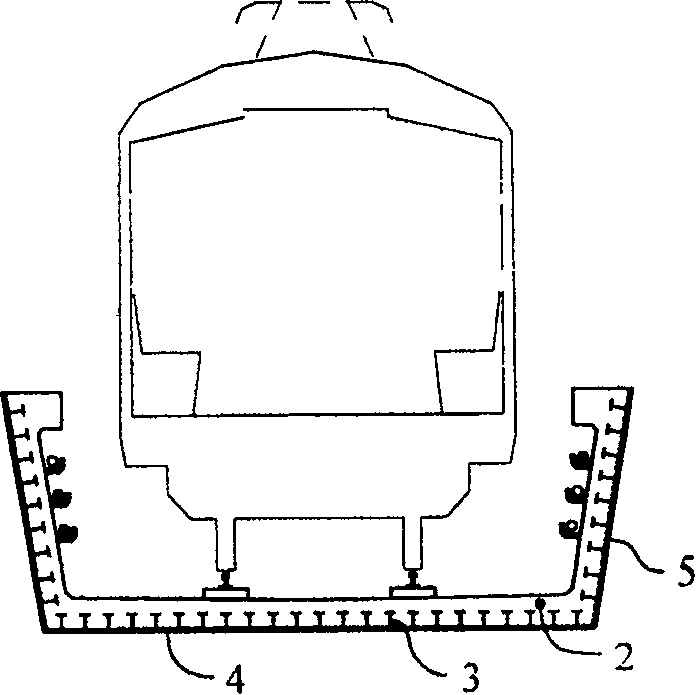

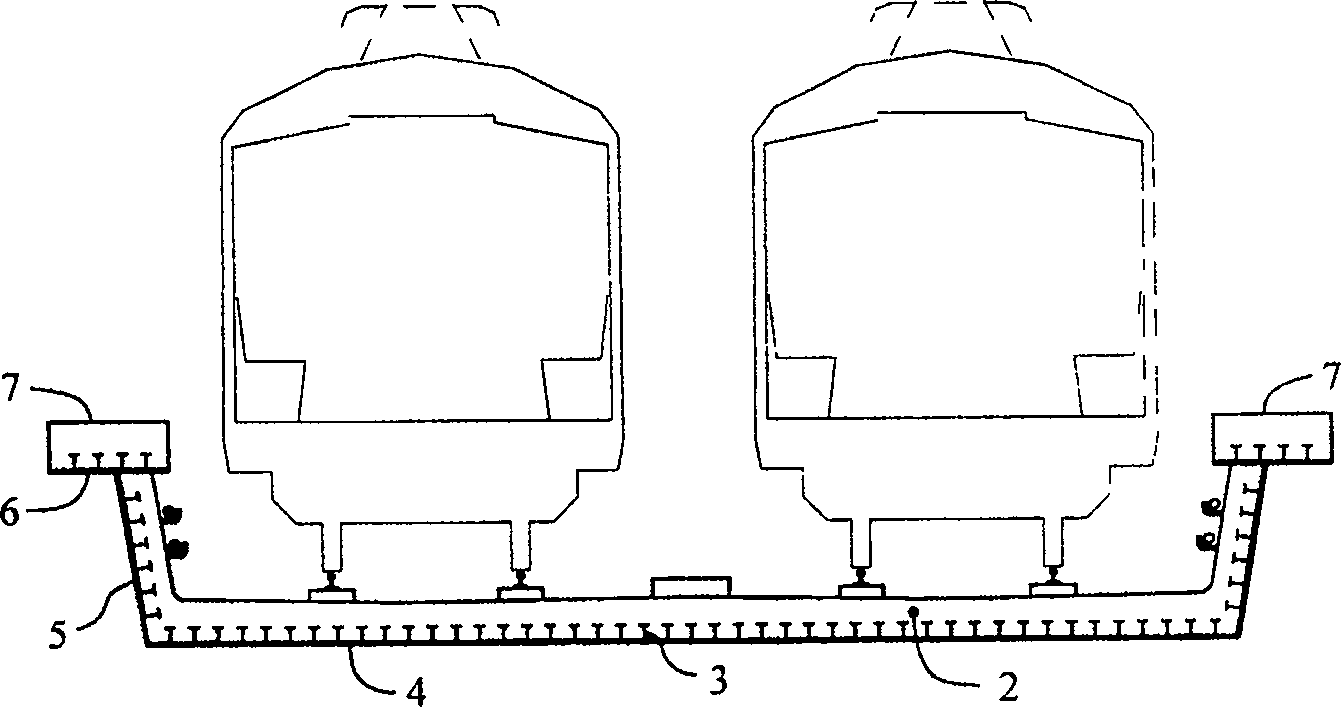

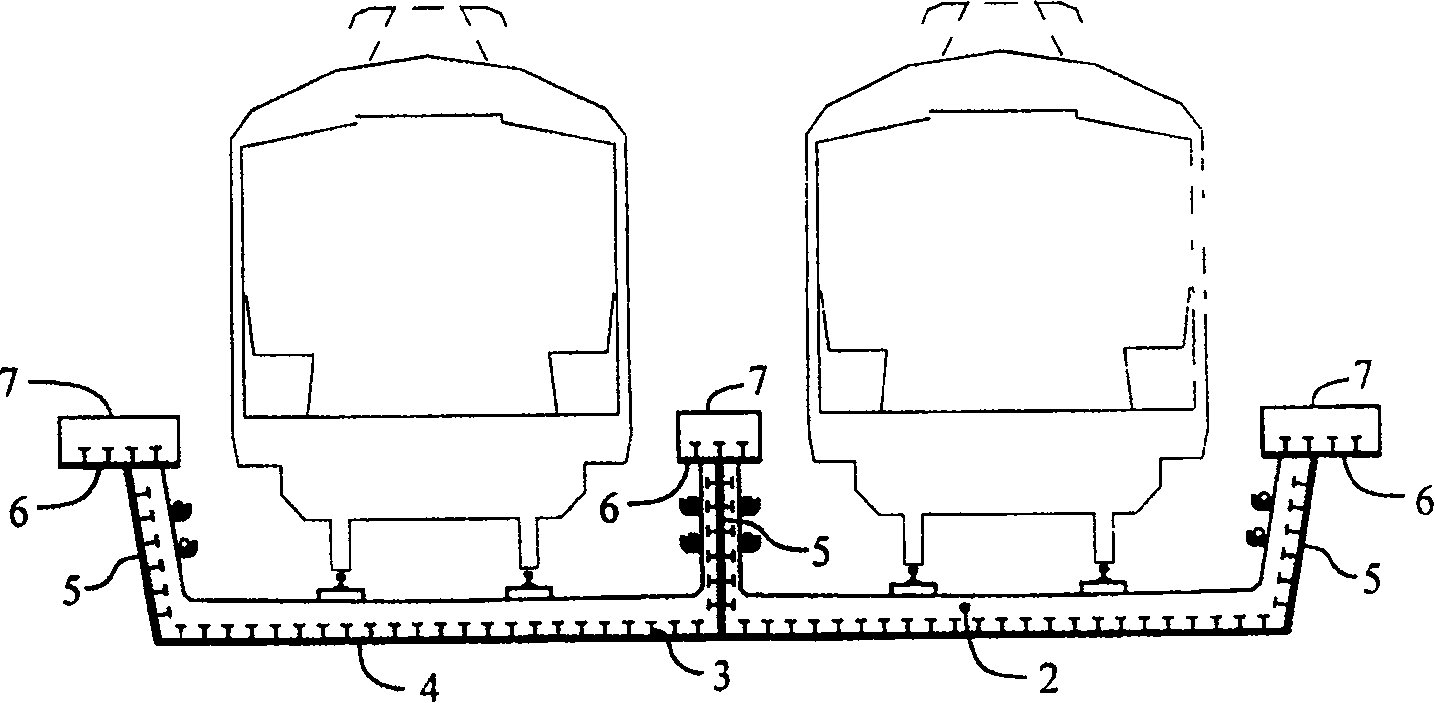

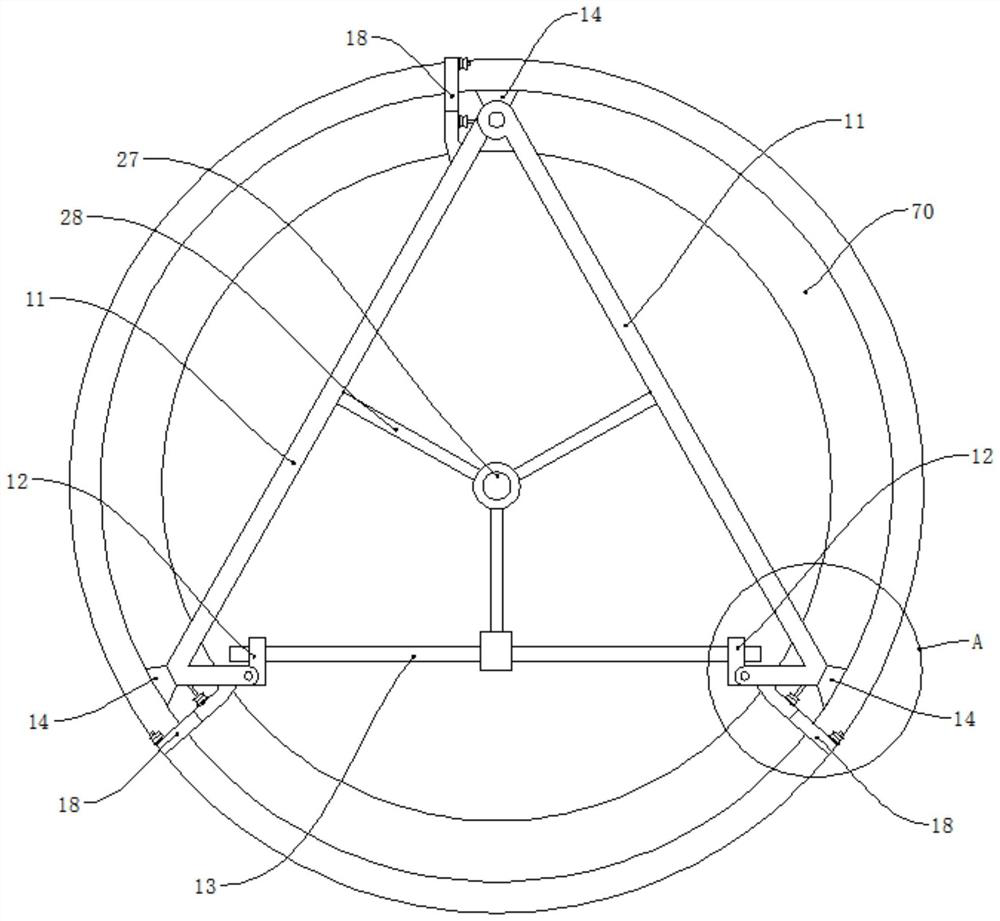

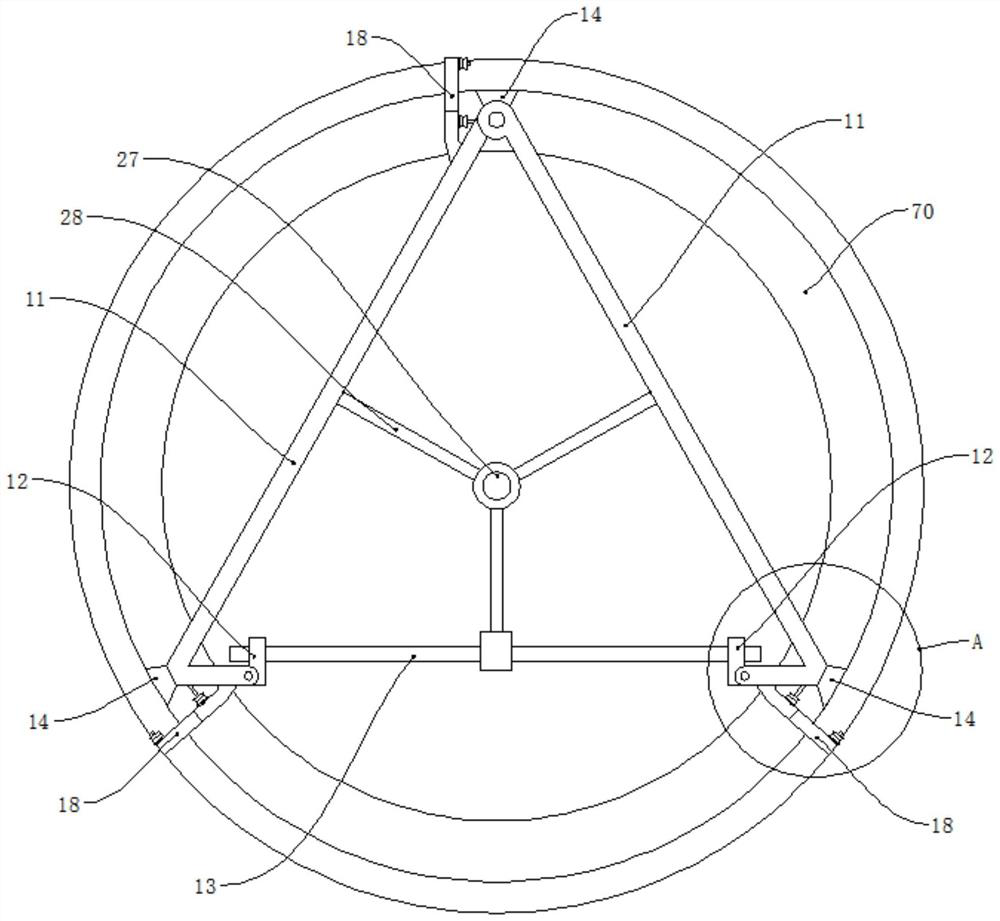

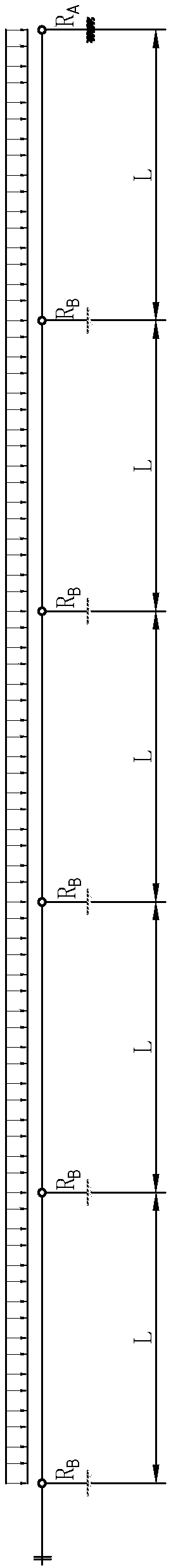

Lower bracket mounting foundation positioning device and method of hydroelectric generating set

ActiveCN104100437AFast installationGuaranteed installation qualityMachines/enginesFoundation engineeringEngineeringClosed state

The invention discloses a lower bracket mounting foundation positioning device and method of a hydroelectric generating set. A fixed connection tray is arranged in the central position of a shaft, and is hinged to one end of each of multiple positioning rods, and the other end of each of the positioning rods is provided with a positioning plate; one end of each of inclined support rods is hinged to the positioning rods from the lower part; a movable connection tray is arranged on the shaft movably in a sleeving manner, and is hinged to the other end of each of the inclined support rods; an upper positioning tray and a lower positioning tray are also arranged on the shaft; the movable connection tray slides between the upper positioning tray and the lower positioning tray; a lifting device is also provided; the lifting device is connected with the movable connection tray. During installation, the positioning rods are in a closed state, and pass through a limited channel to enter into a to-be-installed part. According to the lower bracket mounting foundation positioning device and method of the hydroelectric generating set, the telescoping lower bracket mounting foundation positioning device is adopted, during the construction periods of seat ring processing and stator payingoff processes, a pre-installed lower bracket is subjected to foundation bolt positioning, then the second phase concrete process of casting is performed, the straight line time limit for a project for installation of the generating set is not occupied, a telescoping structure is adopted, and thus installation in place is facilitated.

Owner:CHINA GEZHOUBA GROUP CO LTD

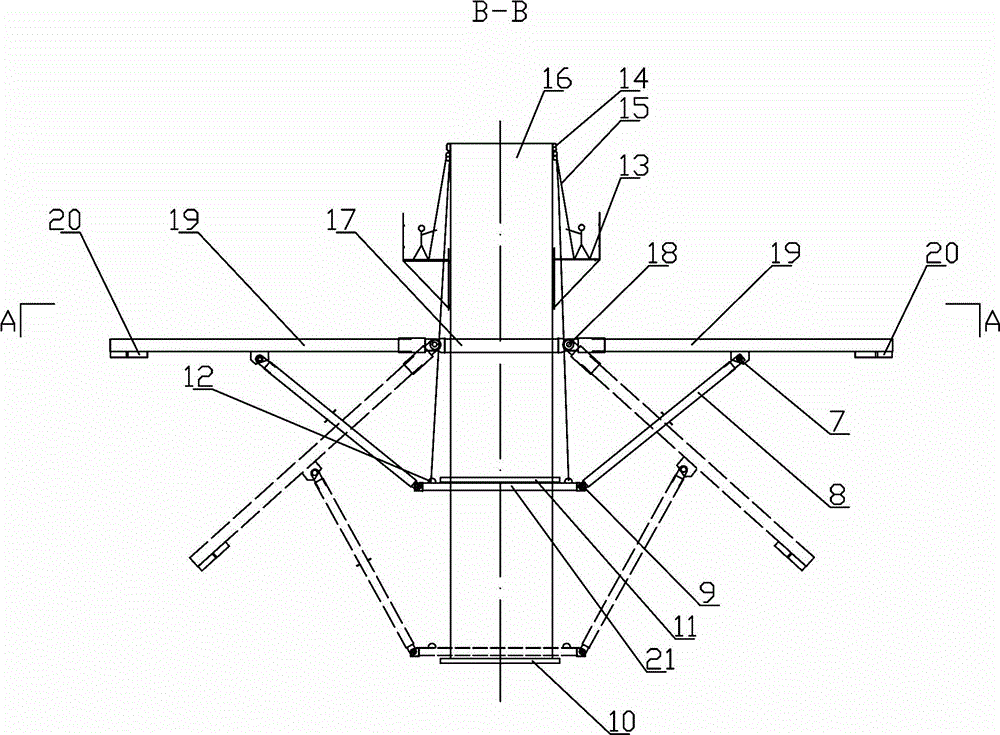

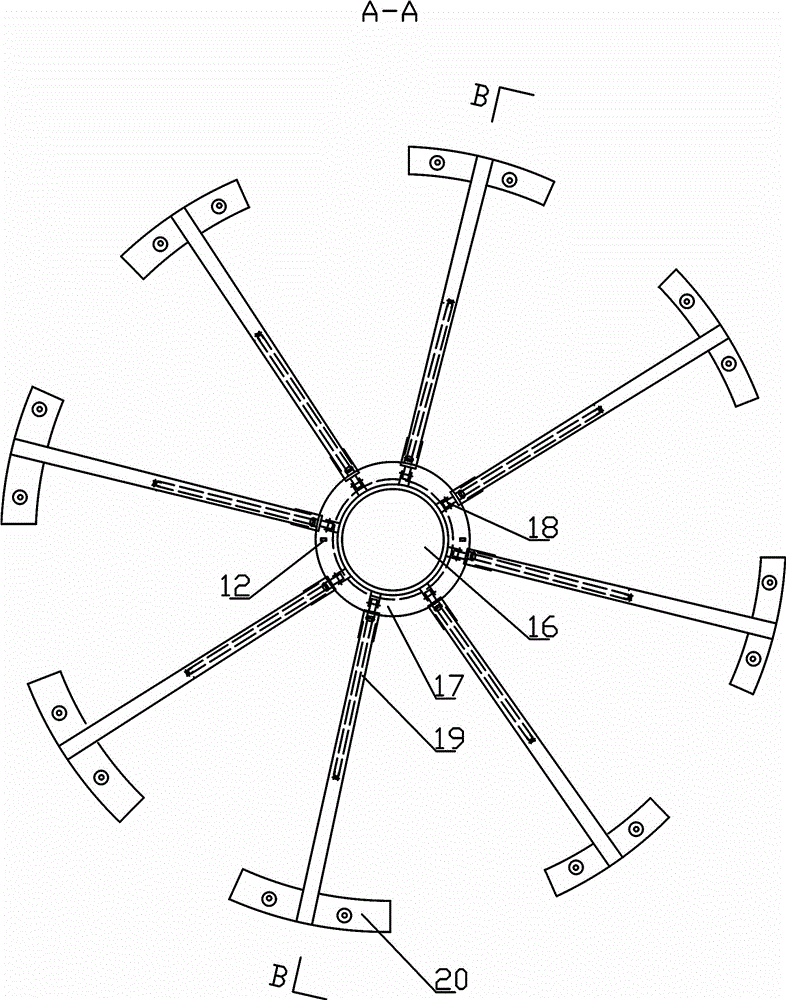

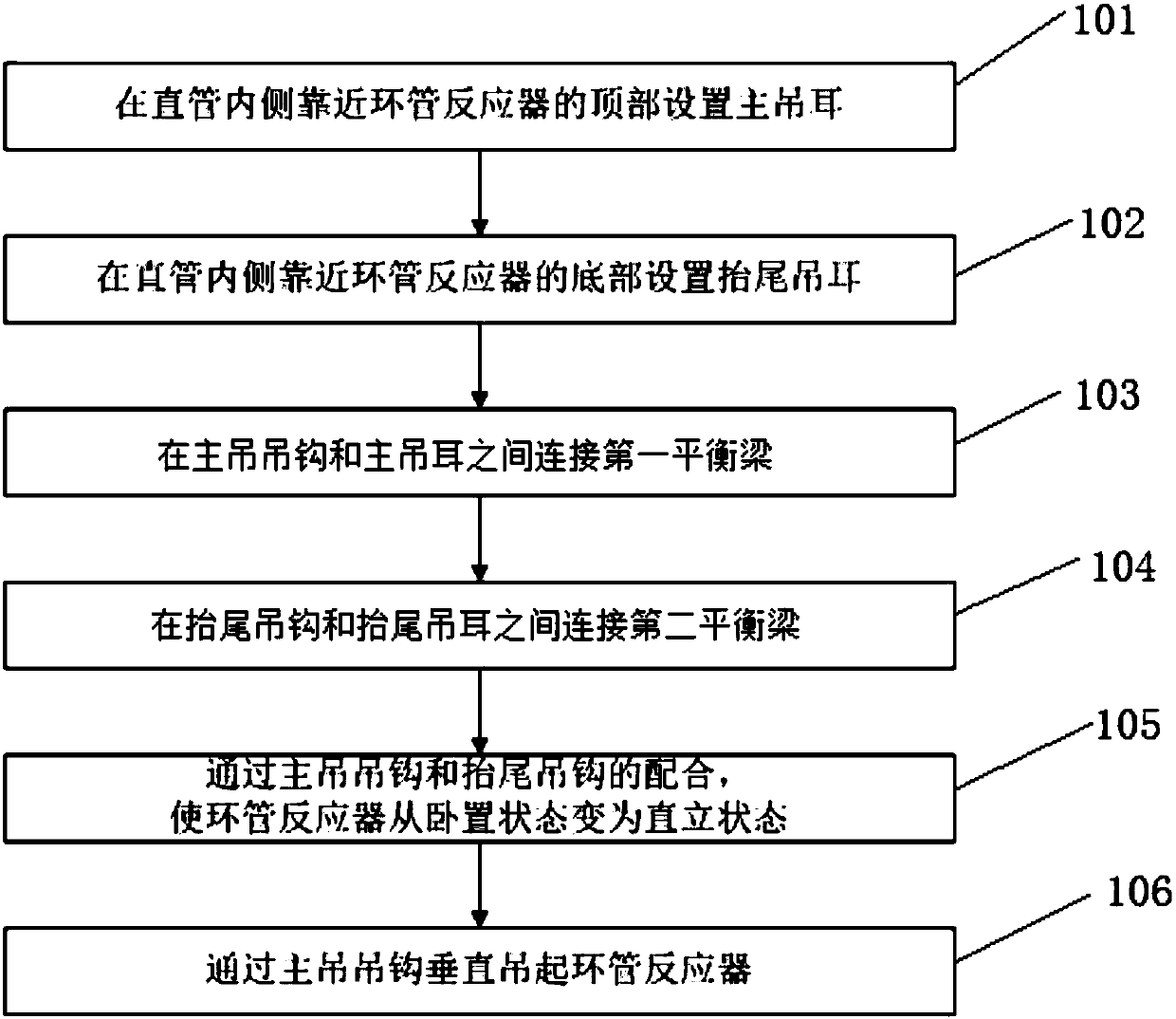

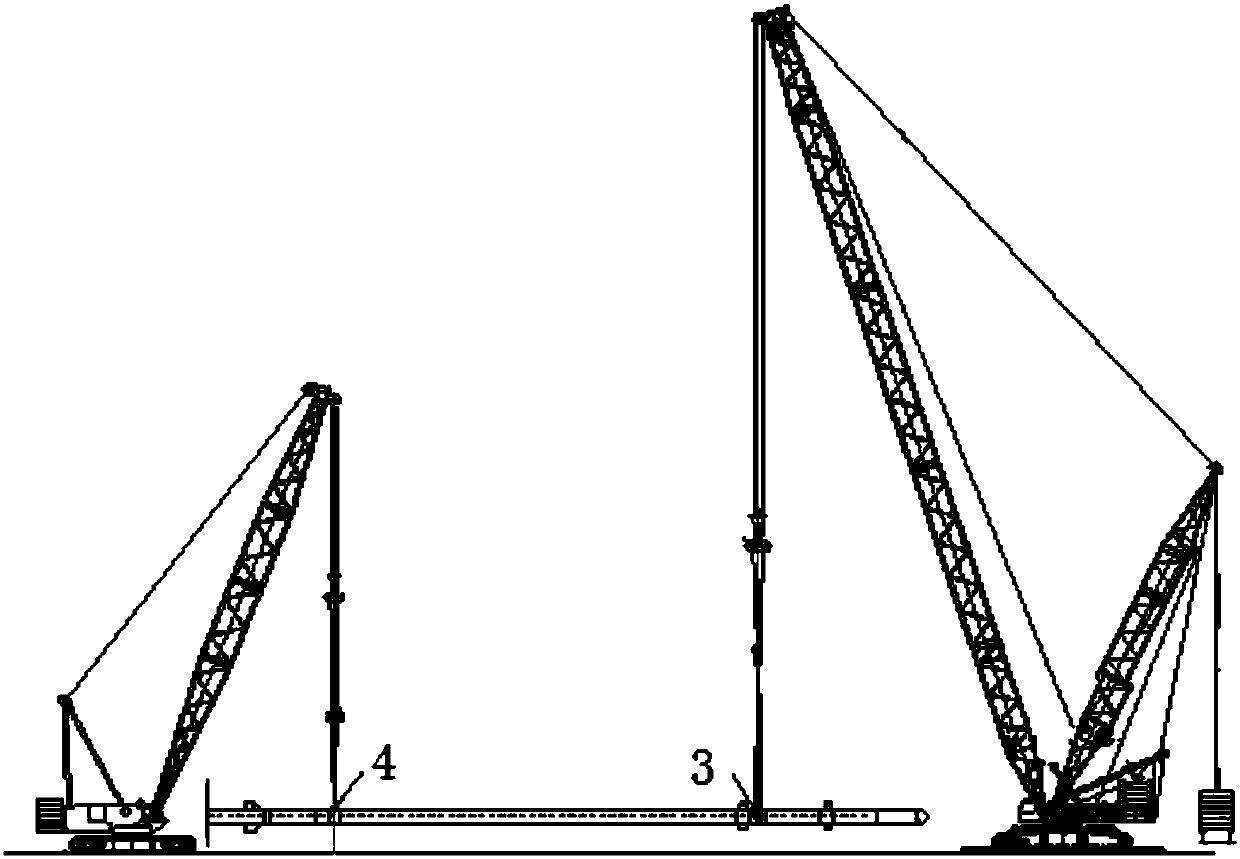

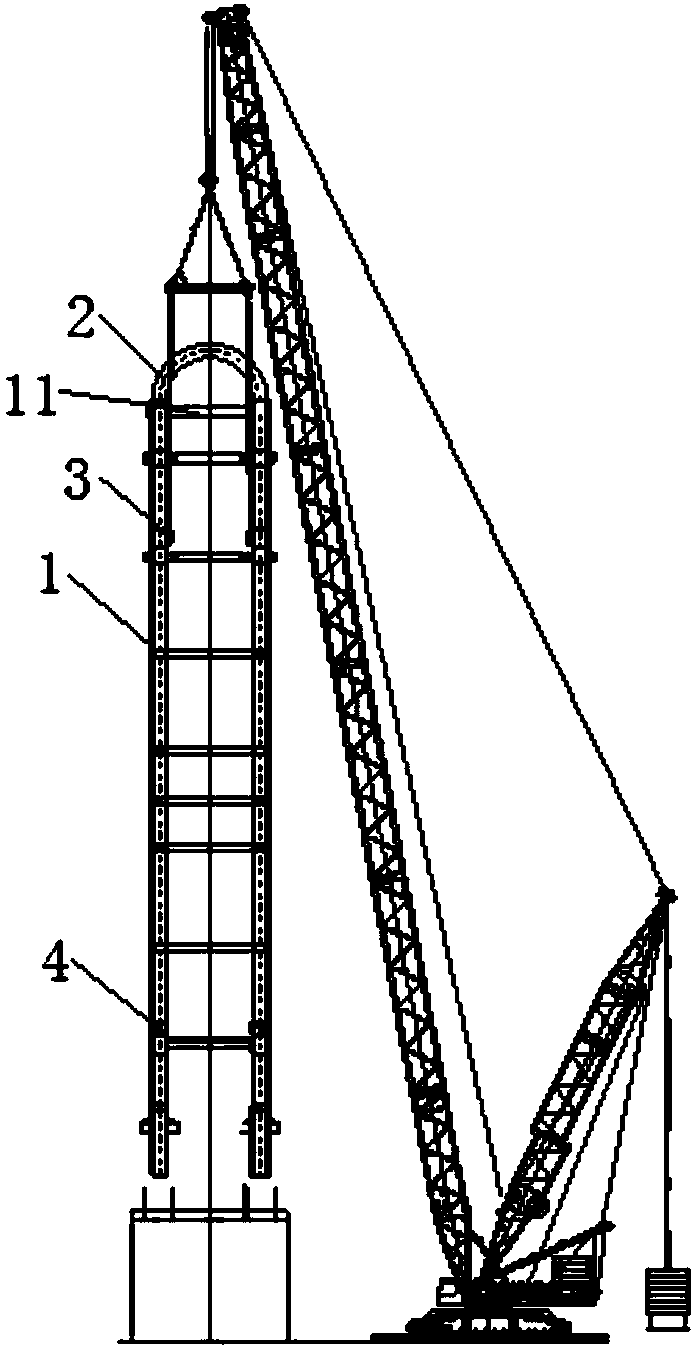

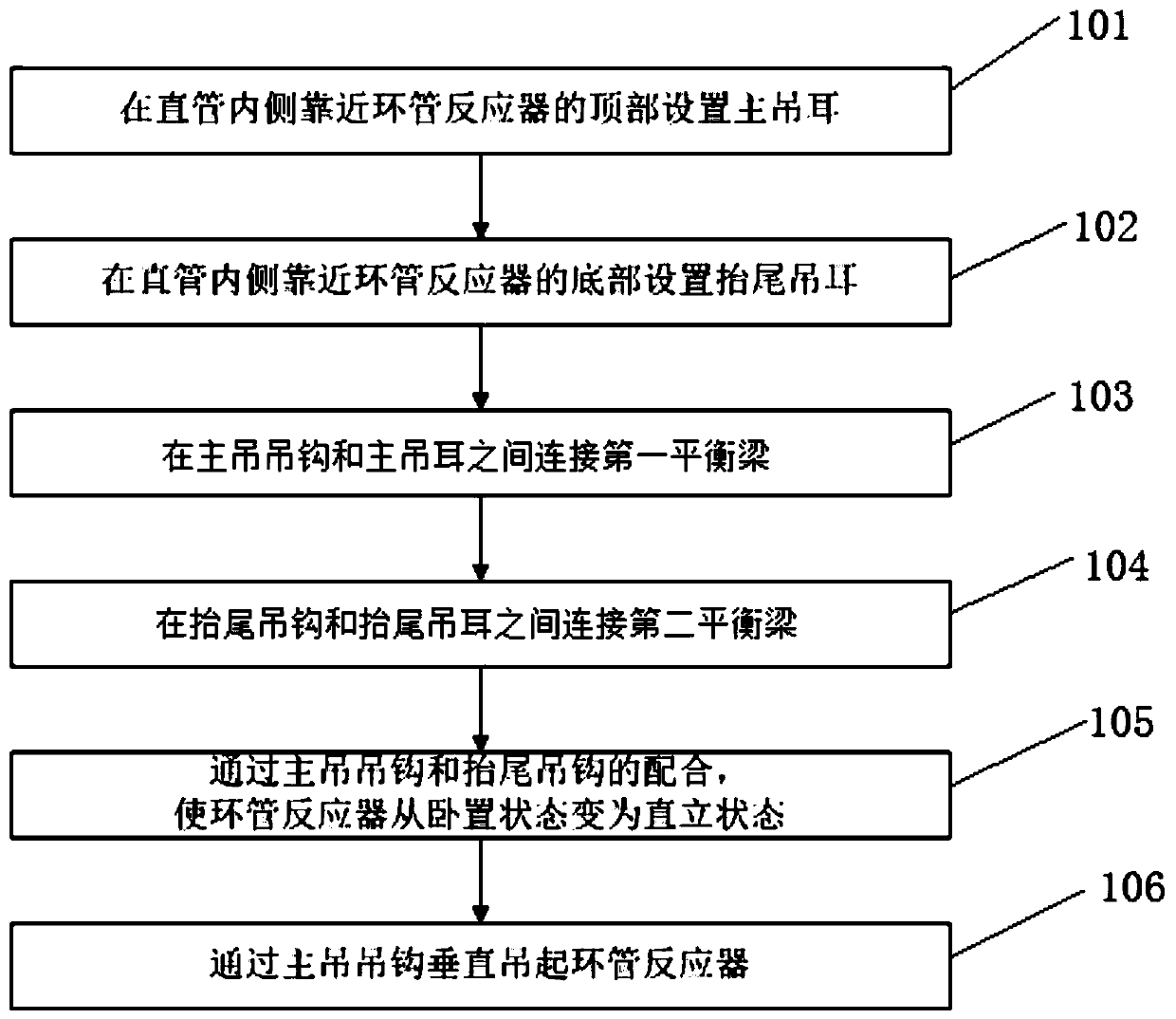

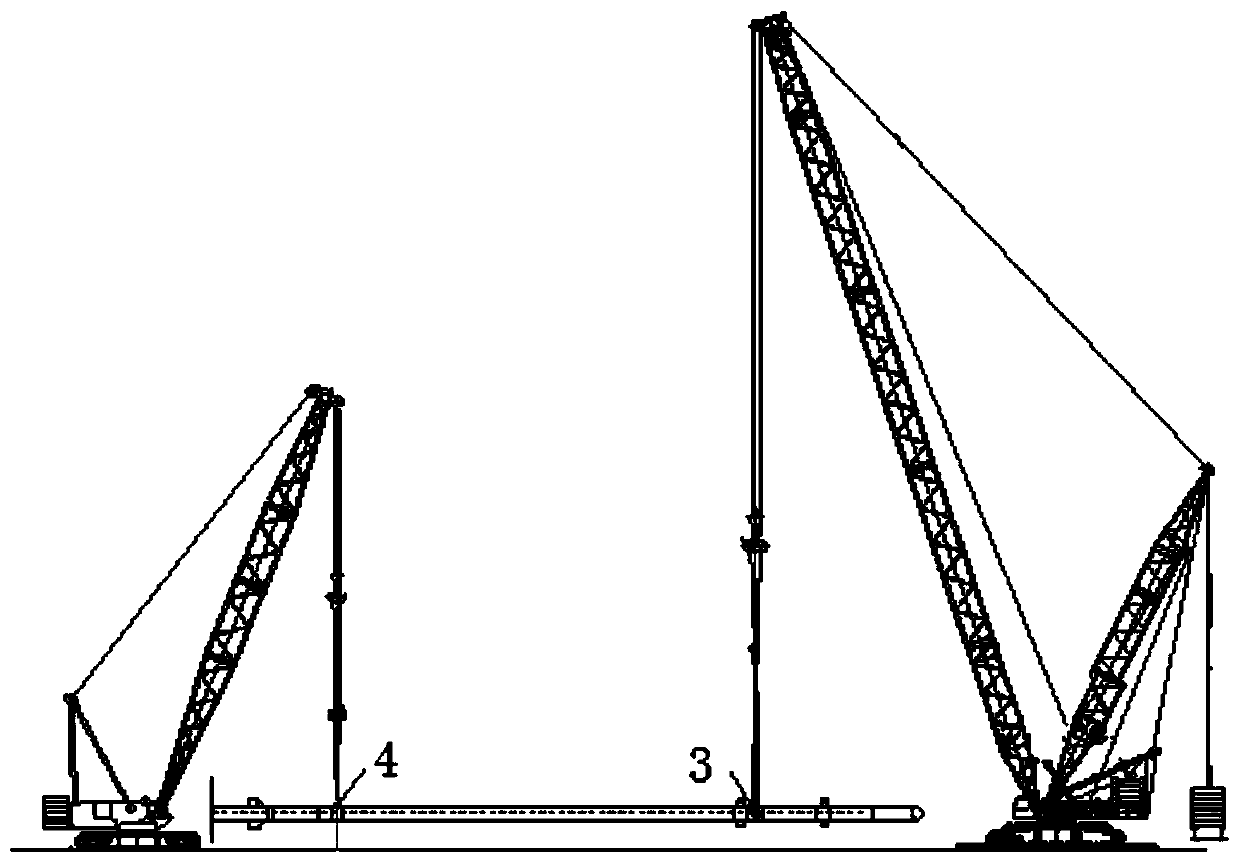

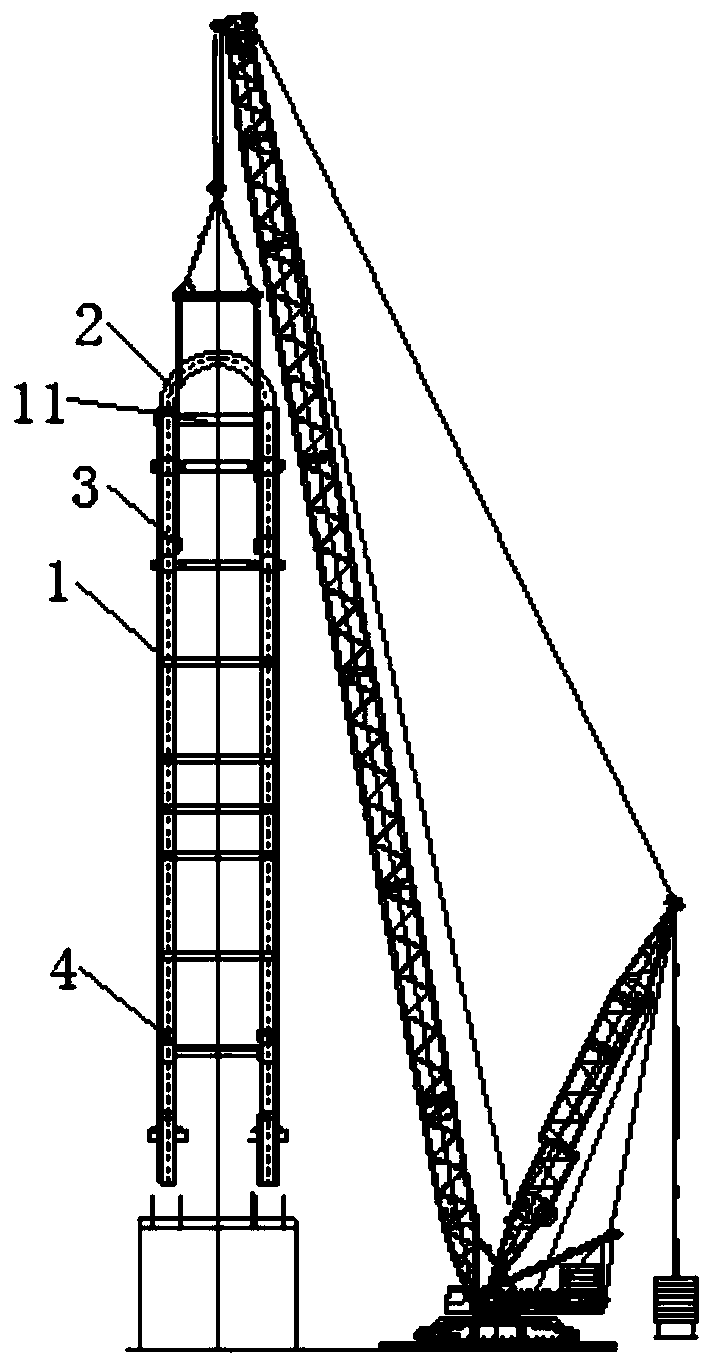

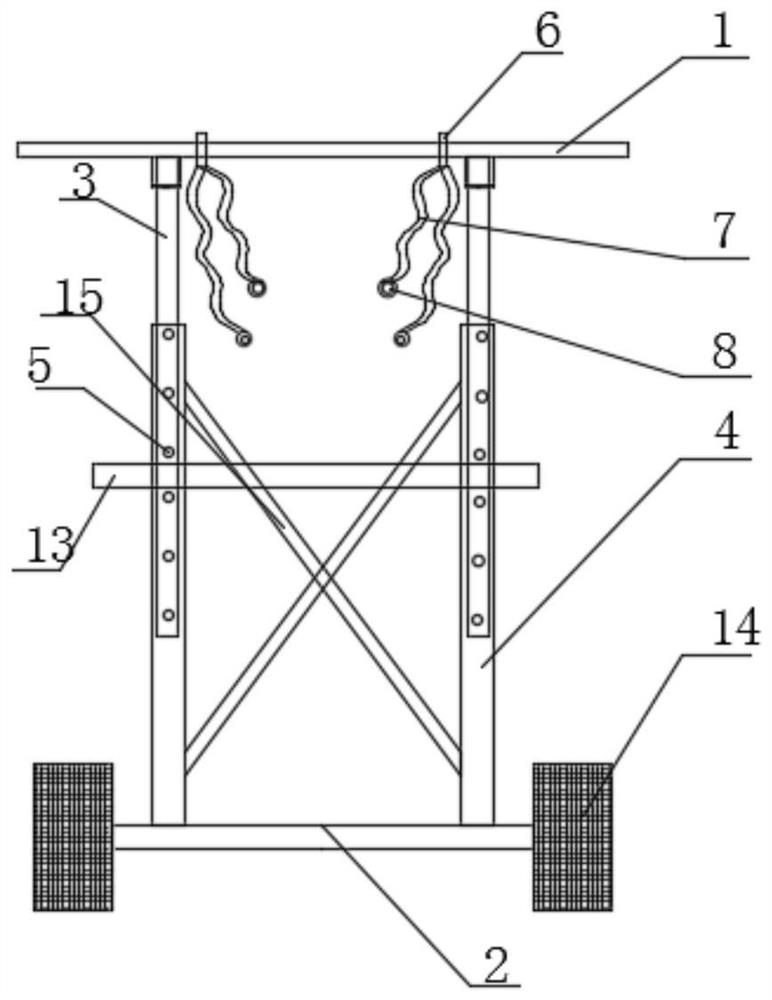

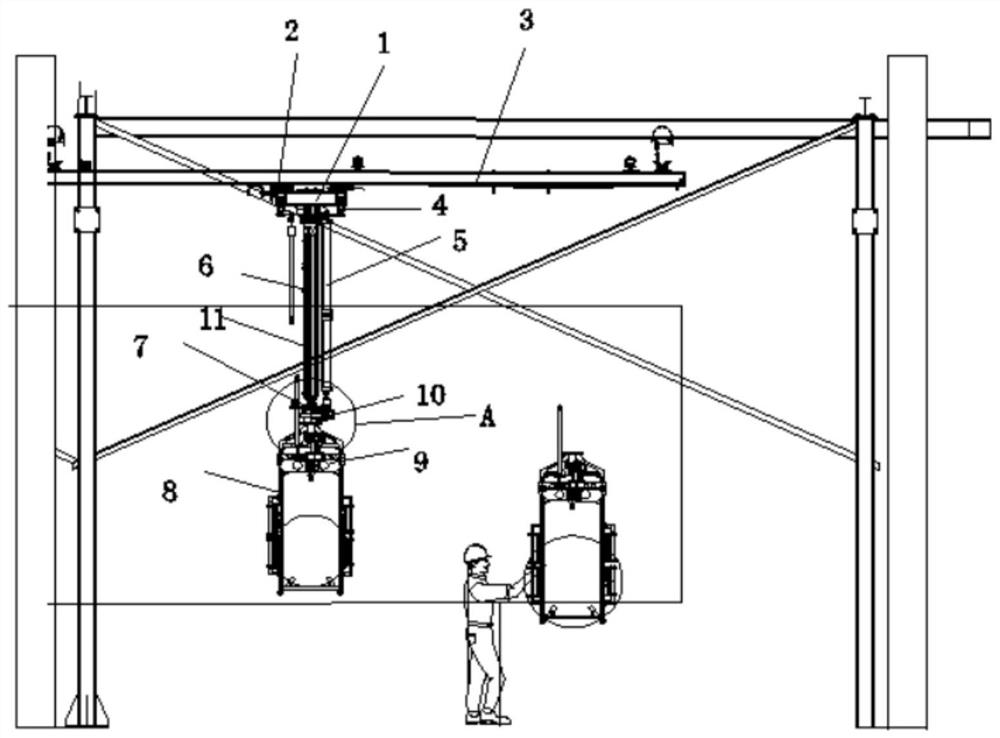

Hoisting method of loop reactor

ActiveCN107758507AFacilitate installation in placeReduce hoisting quality accidentsLoad-engaging elementsEngineering

The invention provides a hoisting method of a loop reactor. The loop reactor comprises two straight pipes, a 180-degree elbow and a connecting beam, wherein the 180-degree elbow and the connecting beam are used for connecting the two straight pipes. The hoisting method of the loop reactor comprises the following steps: arranging a main lug at the top, close to the loop reactor, of the inner side of each straight pipe; arranging a tail holding lug at the bottom, close to the loop reactor, of the inner side of each straight pipe; connecting a first balance beam between a main hoisting hook and each main lug; a second balance beam is connected between a tail holding hoisting hook and each tail holding lug; the main hoisting hooks and the tail holding hoisting hooks are matched to change the loop reactor from a horizontal arranging state into an upright state; the loop reactor is vertically hoisted through the main hoisting hooks. The method hast the advantages that the deformation of theloop reactor in hoisting is small; mounting in place can be performed conveniently; moreover, the mounting quality accident is reduced.

Owner:中石化重型起重运输工程有限责任公司 +1

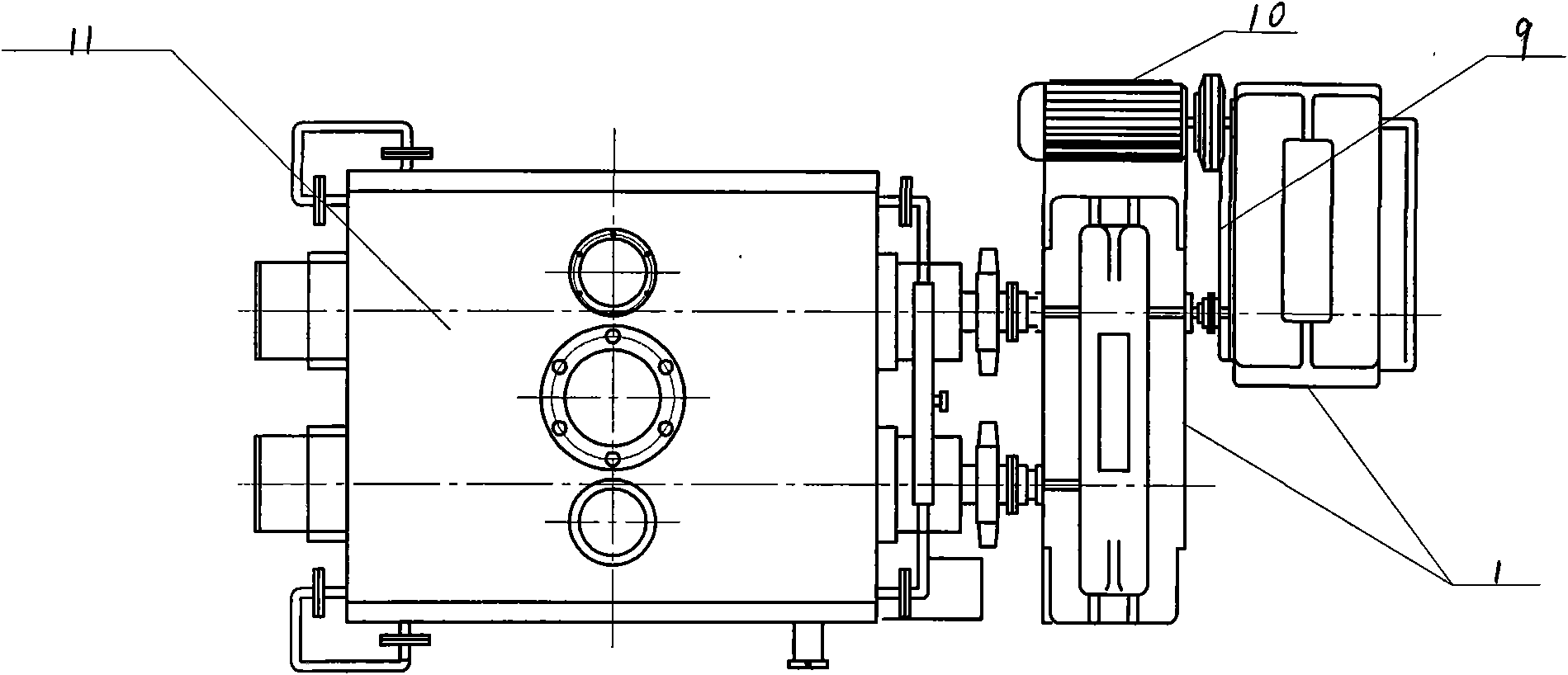

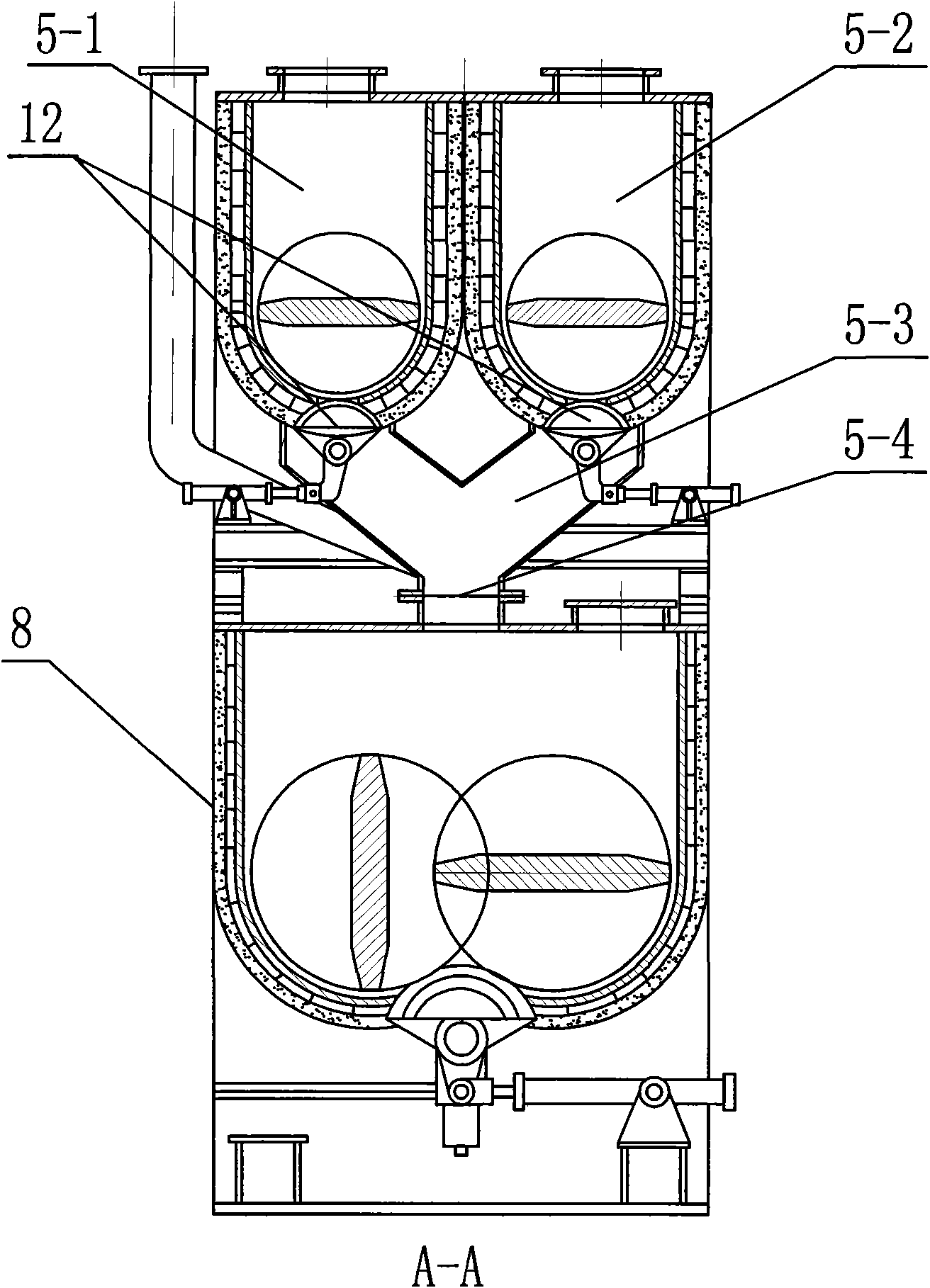

Orderly glue stock kneader

The invention relates to an orderly glue stock kneader which is structured in the following manner: an upper pot body (5) is arranged on the upper surface of a lower pot body (8) through a slideway of the bottom surface thereof, a slideway is arranged on the combining surface of the upper pot body and the lower pot body, a steel ball rolls on the slideway when the upper pot body is moved; a mobile maintenance mechanism (2) is arranged between the upper pot body and the lower pot body; the mobile maintenance mechanism (2) comprises a fixing support (21) the lower end of which is fixed on the lower pot body (8) and a mobile support (17) which is fixed on the upper pot body (5), the upper end of the fixing support (21) is provided with a driving mechanism which drives the upper pot body (5) to move on the lower pot body (8) in a horizontal direction, the outer end of a driving rod of the driving mechanism is connected with the mobile support (17), the mobile maintenance mechanism is arranged between the upper pot body and the lower pot body; the upper pot body can be moved away from the lower pot body by the mobile maintenance mechanism when a reamer in the lower pot body needs repairing.

Owner:YANTAI HUAPENG MACHINERY

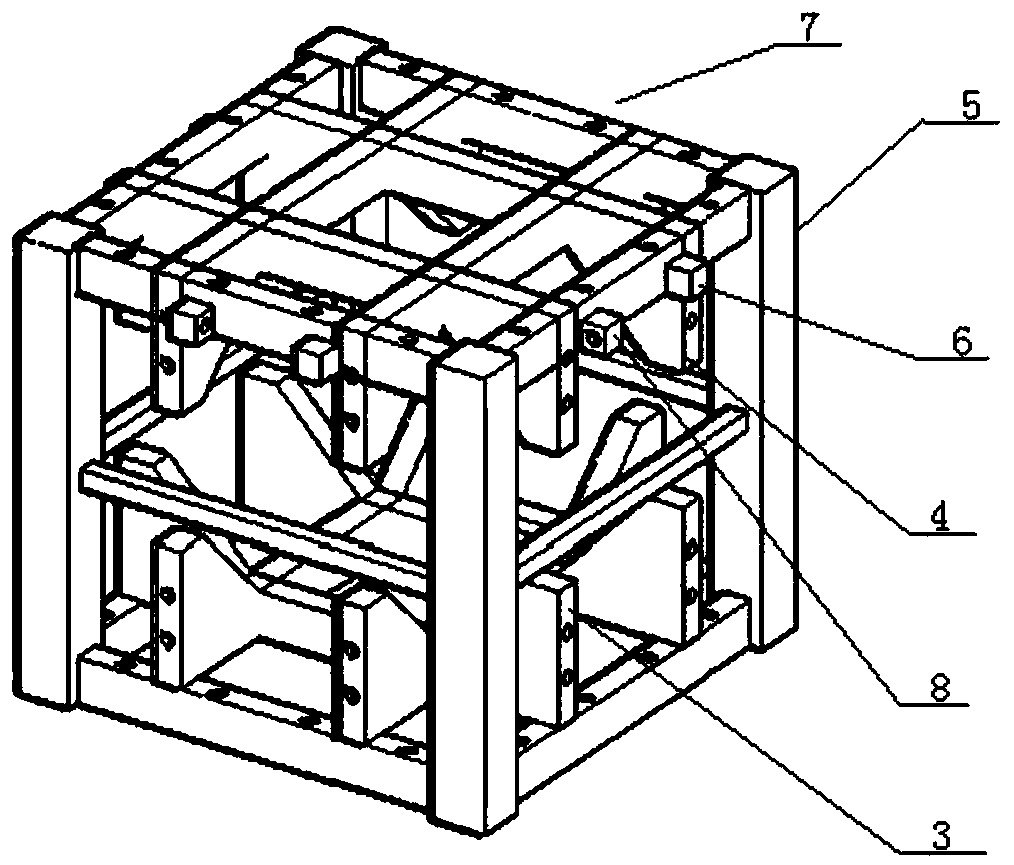

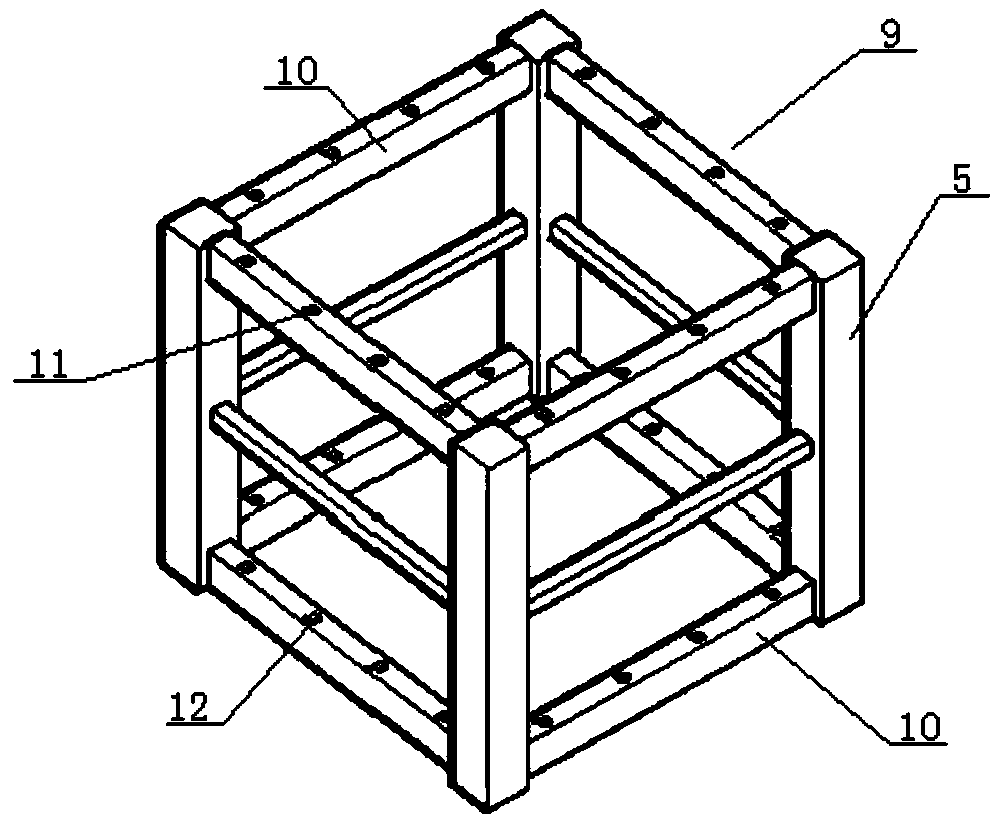

Dry-type beam column connection structure for prefabricated reinforced concrete buildings

InactiveCN108729546AGuaranteed integrityGuaranteed positioning accuracyBuilding constructionsReinforced concreteEngineering

The invention discloses a dry-type beam column connection structure for prefabricated reinforced concrete buildings. The dry-type beam column connection structure is characterized by comprising a hexagonal connection framework and an embedded framework, and one end of the embedded framework is embedded to one or two ends of a prefabricated reinforced concrete beam or vertical column. The connection framework is positioned on the top surface of a vertical column or between upper and lower vertical columns and fixedly connected with the embedded framework on the end face of the vertical column through bolts, and beams are arranged on the lateral sides of the connection framework and fixedly connected with the connection framework through the embedded framework by the aid of bolts. The dry-type beam column connection structure has advantages of high connection strength, short construction period, high construction precision, high structural integrity, convenience in mounting and surface attractiveness.

Owner:NORTHEAST DIANLI UNIVERSITY

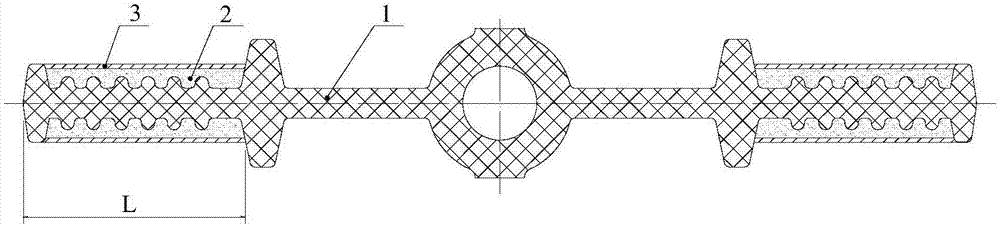

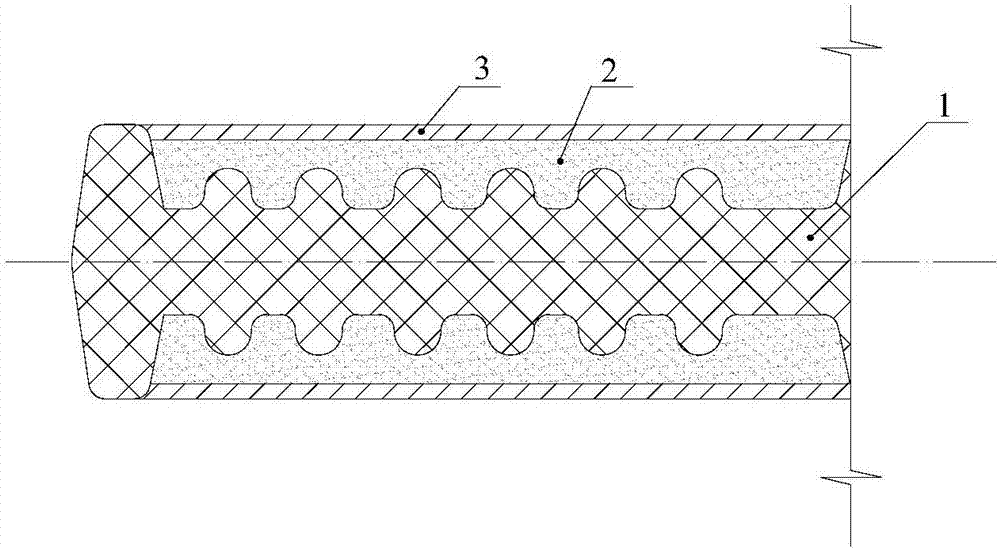

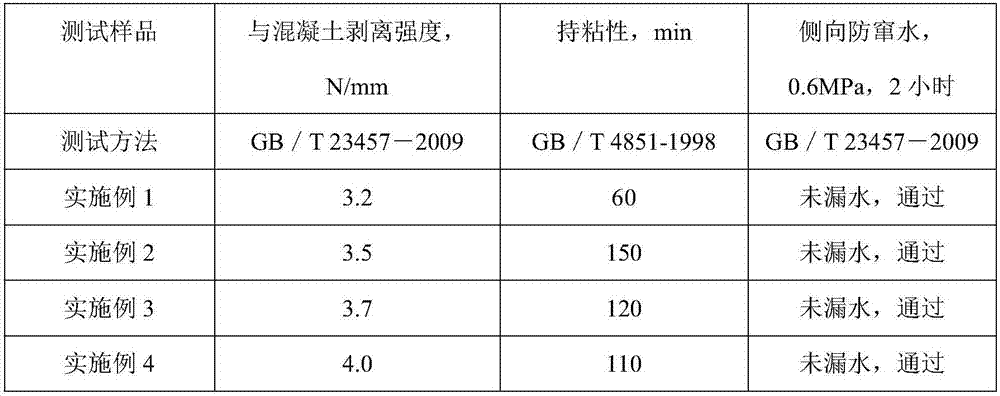

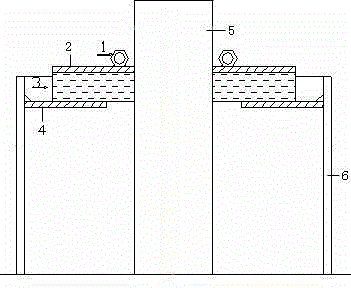

Self-adhesive type water stop and production method

InactiveCN107044139AImprove installation and construction efficiencyImprove waterproof performanceMineral oil hydrocarbon copolymer adhesivesArtificial islandsSolid BondEngineering

The invention discloses a self-adhesive type water stop and a production method for effectively improving the installation construction efficiency and the waterproof performance of the water stop. The self-adhesive type water stop comprises water stop base material, the two ends in the transverse direction of the water stop base material are water stop sections, the upper surface and the lower surface of the water stop sections are coated with hot-melt pressure-sensitive adhesive to form waterproof adhesive layers, and the waterproof adhesive layers are externally covered with insulating layers which form bonds with the waterproof adhesive layers. The peel strength and the holding viscosity with concrete of the prepared and adopted hot-melt pressure-sensitive adhesive are far larger than an existing hot-melt pressure-sensitive adhesive, and the hot-melt pressure-sensitive adhesive can form a solid bond with a new pouring concrete structure to ensure that the water stop has excellent adhesion and waterproof performances.

Owner:四川迈铁龙科技有限公司 +1

Vertical mixed connection structure and method of prefabricated internal wallboards for assembling shear wall structure

The invention discloses a vertical mixed connection structure and method of prefabricated internal wallboards for assembling a shear wall structure. On the structure, edge components of upper-layer and lower-layer prefabricated internal wallboard structures are overlapped through vertical steel bars and U-shaped ribs, and horizontal reinforcing ribs and local cast-in-place concrete are arranged in a closed ring so as to realize the edge components equivalent to the cast-in-place concrete, the vertically distributed steel bars at the middle part of the components are connected in a manner of indirect overlapping by use of mortar anchor steel bars of a retention metal mortar anchor pipe so as to form an entire shear wall. By utilizing the local cast-in-place concrete moist joint at the edge component part formed by the mixed connection and the dry joint of bedding and grouting at the part of the vertically distributed steel bars, the shear strength and rigidity of the horizontal jointing part of the prefabricated internal wallboards are improved; casting holes reserved at the bottom of the edge components can be used for solving the problem of casting the local cast-in-place concrete; and the vertically distributed steel bars are connected in a manner of indirect overlapping by use of the mortar anchor, which facilitates the installation and temporary fixation of the wallboards on a concrete floor. The mixed connection structure of the prefabricated internal wallboards, provided by the invention, ensures the overall performance of the shear wall; and construction is convenient.

Owner:SOUTHEAST UNIV

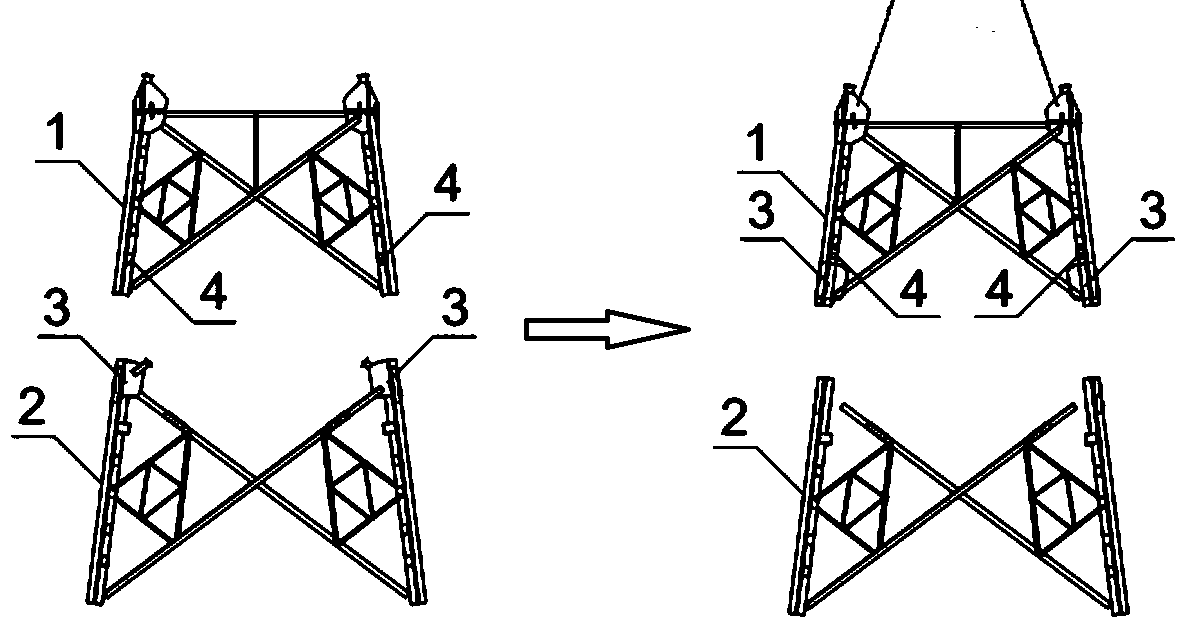

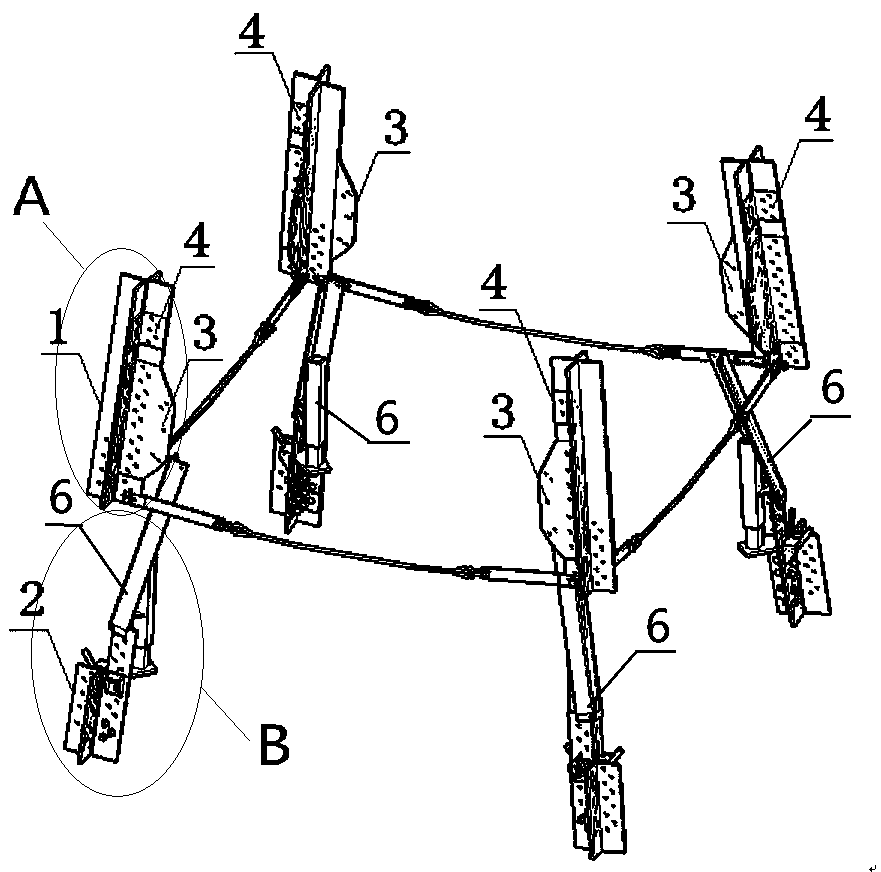

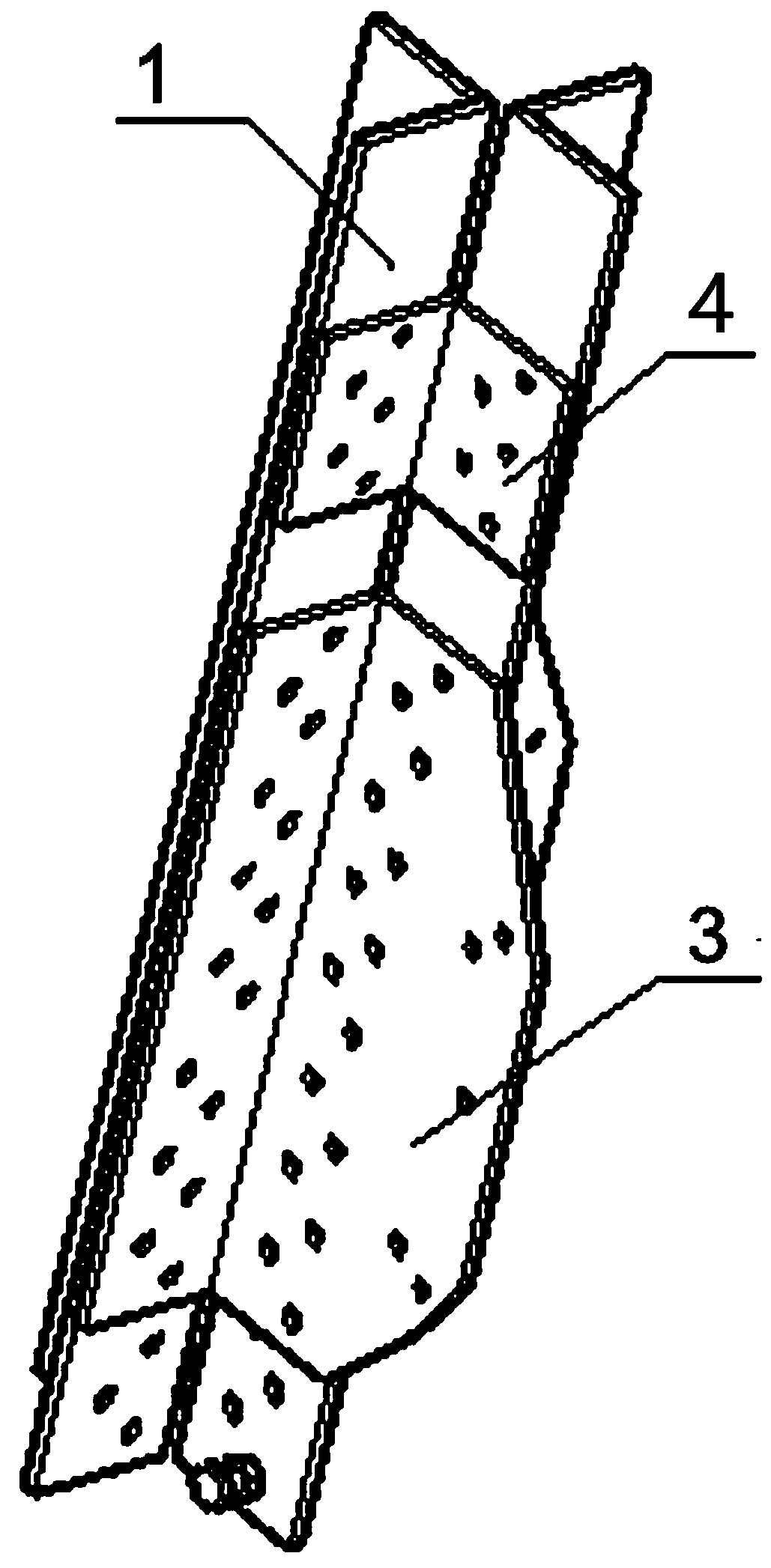

Construction method for erecting electric transmission line double-leg angle steel tower by helicopter unit

The invention discloses a construction method for erecting an electric transmission line double-leg angle steel tower by a helicopter unit, and relates to the field of electric transmission line irontower construction. When a helicopter unit is used for erecting the double-leg angle steel tower, due to the fact that between-section cross-shaped connecting plates are installed on tower sections, difference exists between the root distance sizes of the lifting tower sections and the in-position tower sections, and being in-position is difficult. The construction method comprises the following steps that (1) the between-section cross-shaped connecting plates and main material cross-shaped connecting plates are installed on the lifting tower sections; (2) inner angle wrapping steel and outerangle wrapping steel of the in-position tower sections are connected with and fixed to inner main materials and outer main materials correspondingly, and then abutting auxiliary sleeve pieces are installed on the inner angle wrapping steel and the inner main materials correspondingly; (3) a helicopter hovers and operates to guide the tower sections to be in position through the abutting auxiliarysleeve pieces of the tower sections; after the tower sections are in position, high-altitude personnel installs a small quantity of bolts on two sides of abutting points of the tower sections, and thehelicopter unhooks and leaves; and (5) remaining bolts are installed in a supplementary mode, and the abutting auxiliary sleeve pieces are detached. According to the construction method for erectingthe electric transmission line double-leg angle steel tower by the helicopter unit, the problem of difficult position taking caused by significant difference of the root distance sizes of the liftingtower sections and the in-position tower sections is solved.

Owner:浙江省送变电工程有限公司 +3

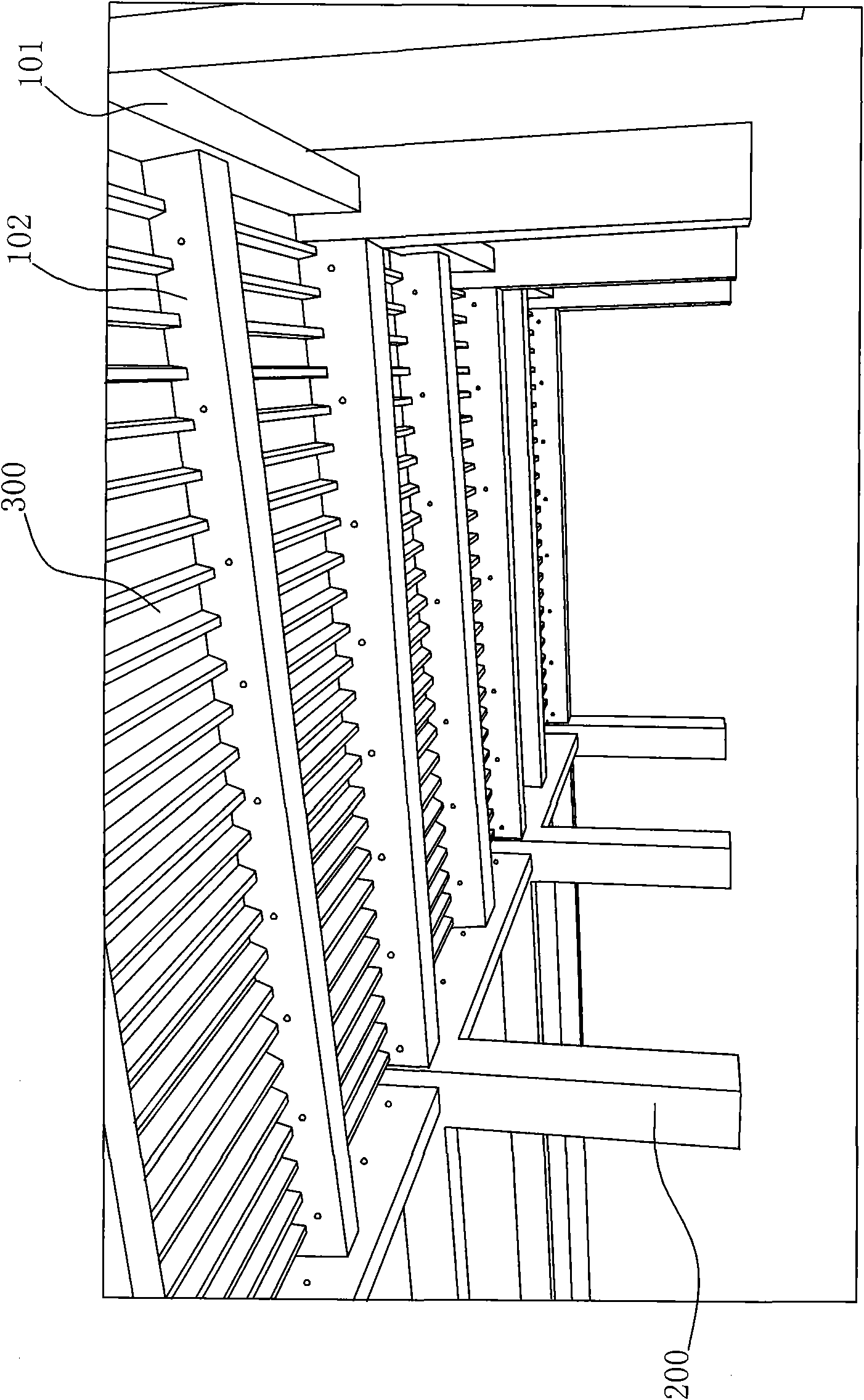

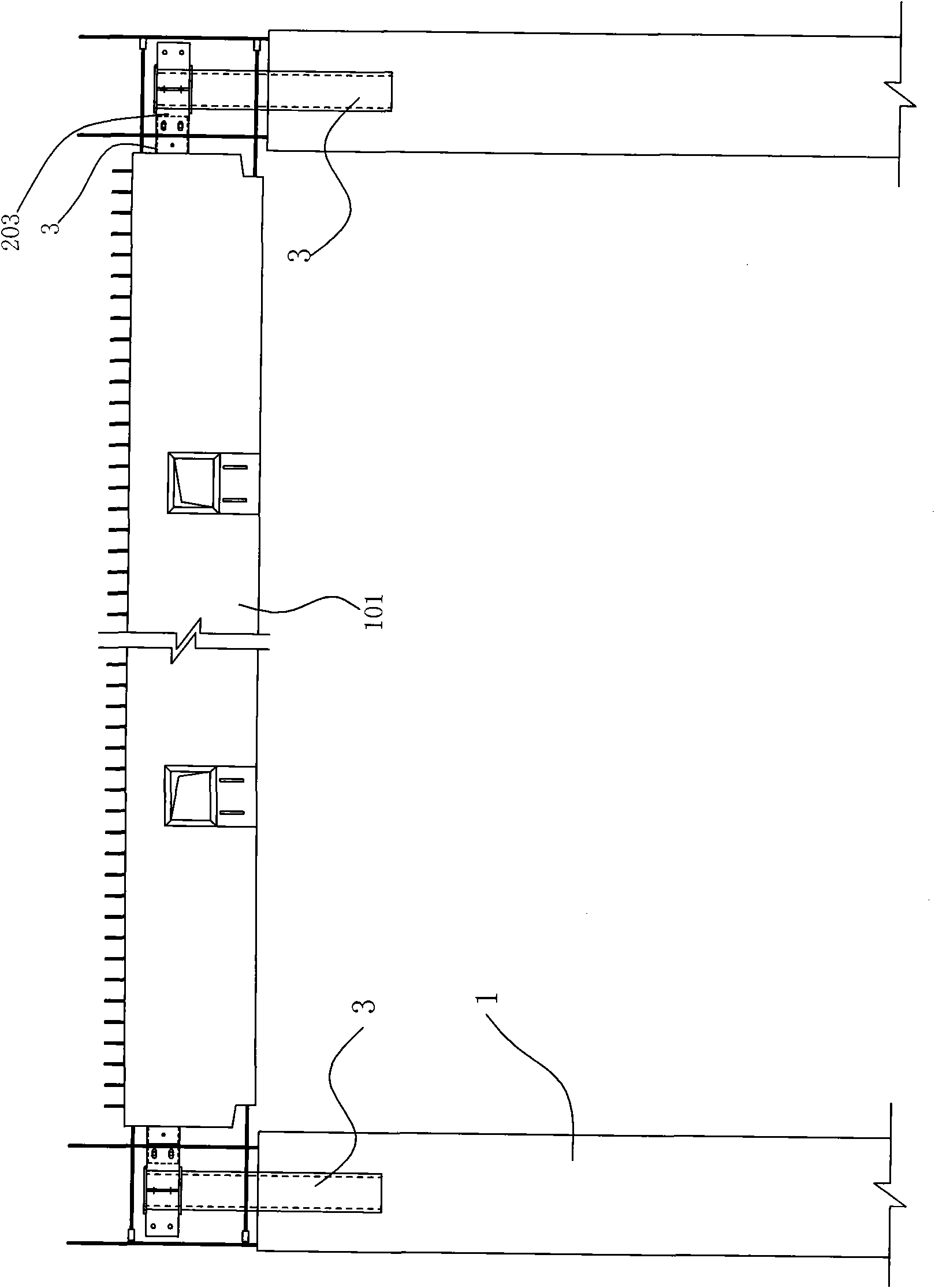

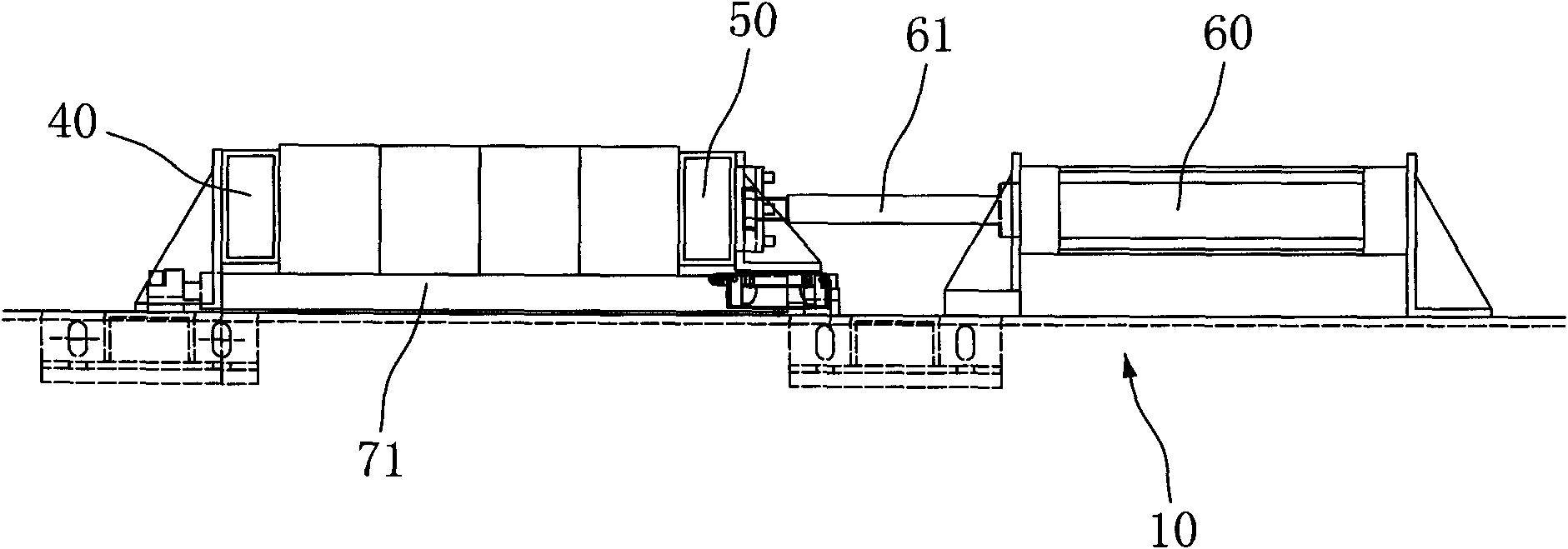

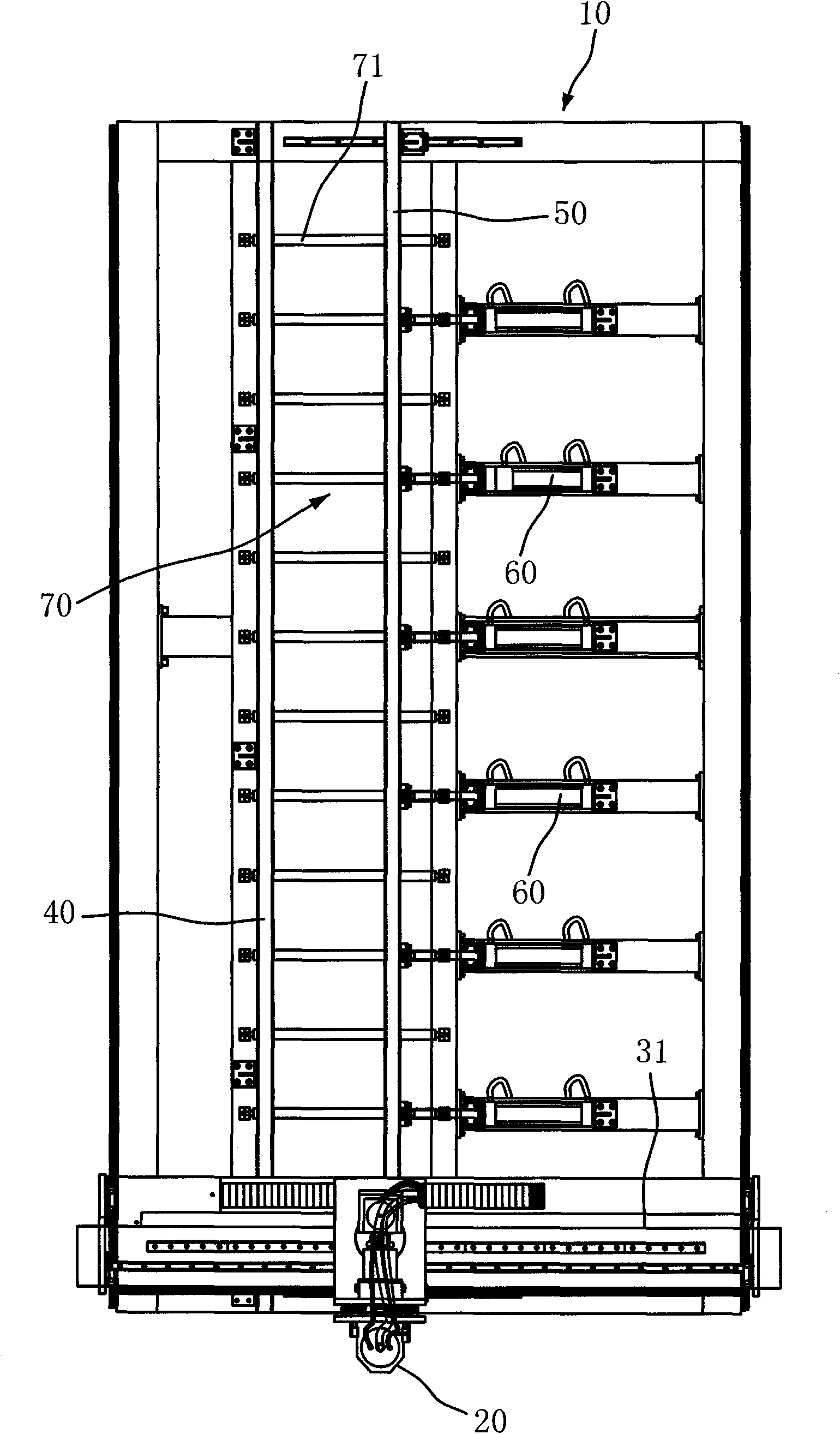

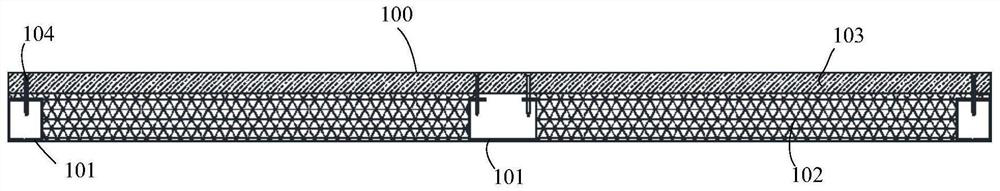

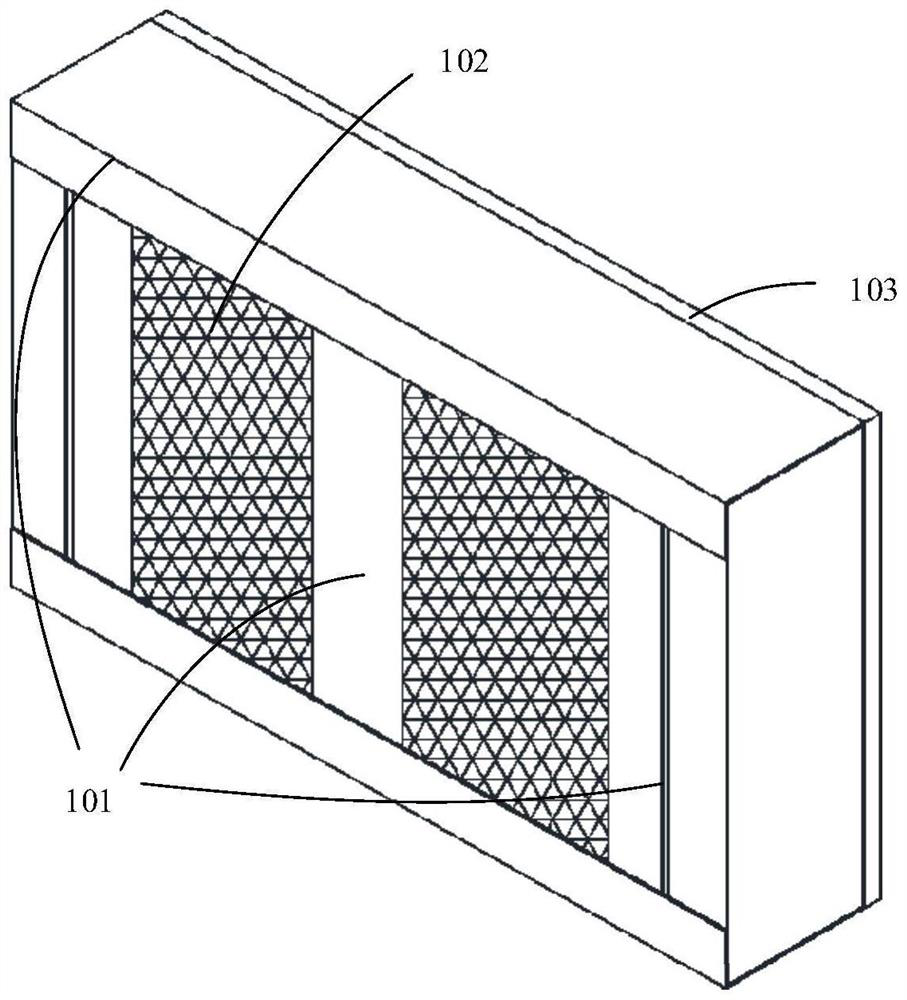

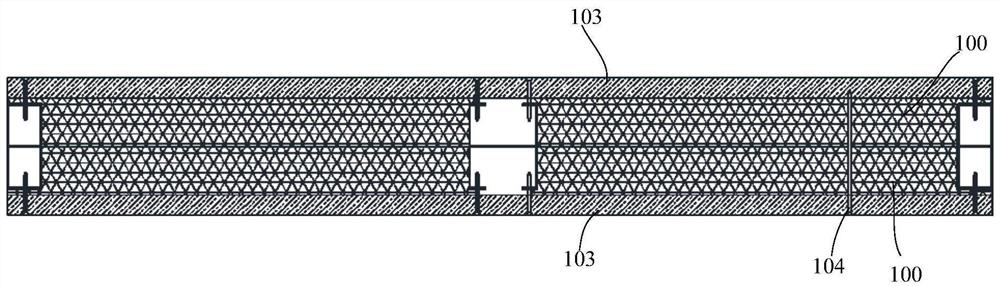

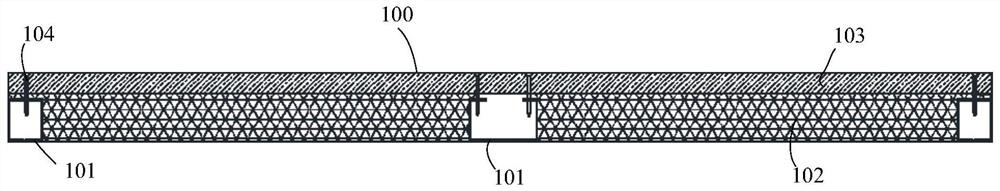

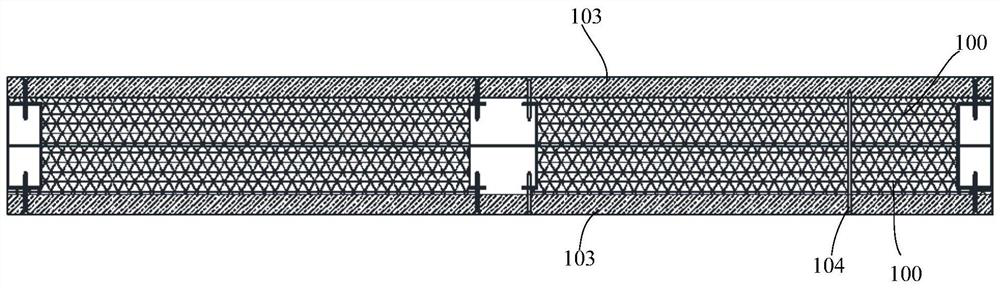

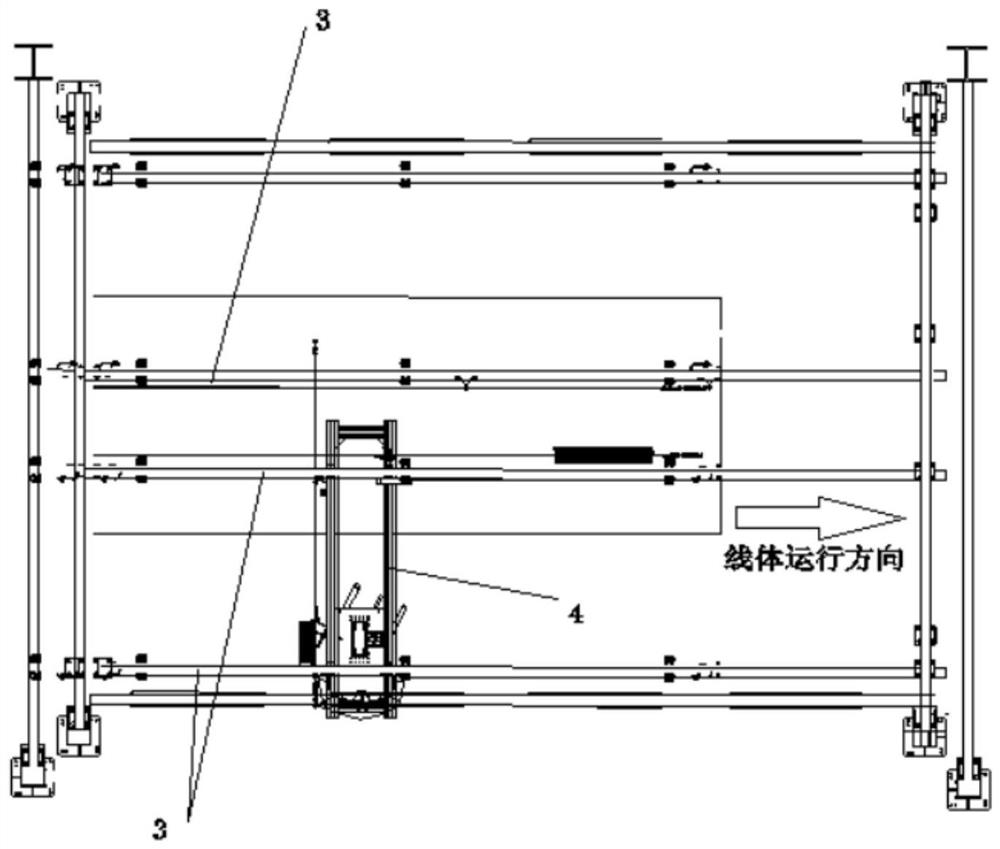

Assembled wall board production line

ActiveCN111618917AOvercoming low productivityEfficient and fast productionMetal working apparatusMetal-working hand toolsWall plateManufacturing line

The invention discloses an assembled wall board production line. The assembled wall board production line comprises an assembling platform, a keel loading mechanism, a wall panel loading mechanism, aheat-insulation material loading mechanism, a nailing mechanism, and automatic grabbing mechanisms, wherein an assembling plane is formed at the upper end of the assembling platform; the keel loadingmechanism is arranged at one side of the assembling platform; the wall panel loading mechanism is arranged at the other side of the assembling platform in a manner of being relative to the keel loading mechanism; the heat-insulation material loading mechanism is connected with the assembling platform; the nailing mechanism is arranged on the assembling platform; and the automatic grabbing mechanisms are arranged at the two sides of the assembling platform in a manner of corresponding to the keel loading mechanism and the wall panel loading mechanism. The invention relates to the field of assembled wall body production, and provides an assembled wall board production line. The problem of low production efficiency can be overcome, large-scale production is formed, and an assembled wall boardcan be efficiently and rapidly produced; and meanwhile, the production quality is also ensured.

Owner:BEIJING NEW BUILDING MATERIAL

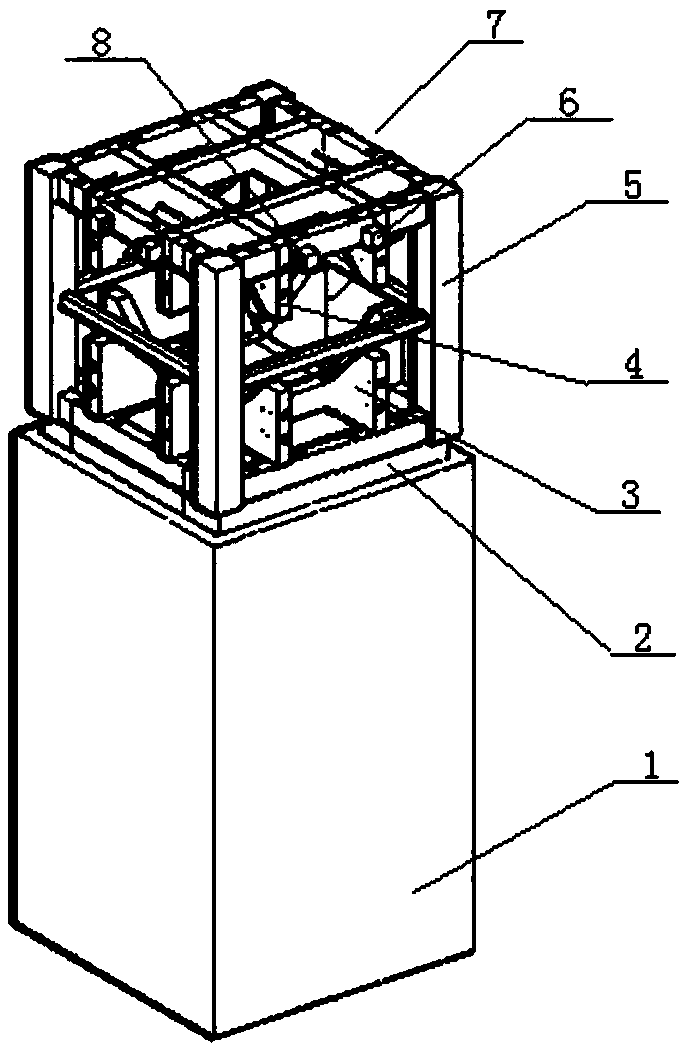

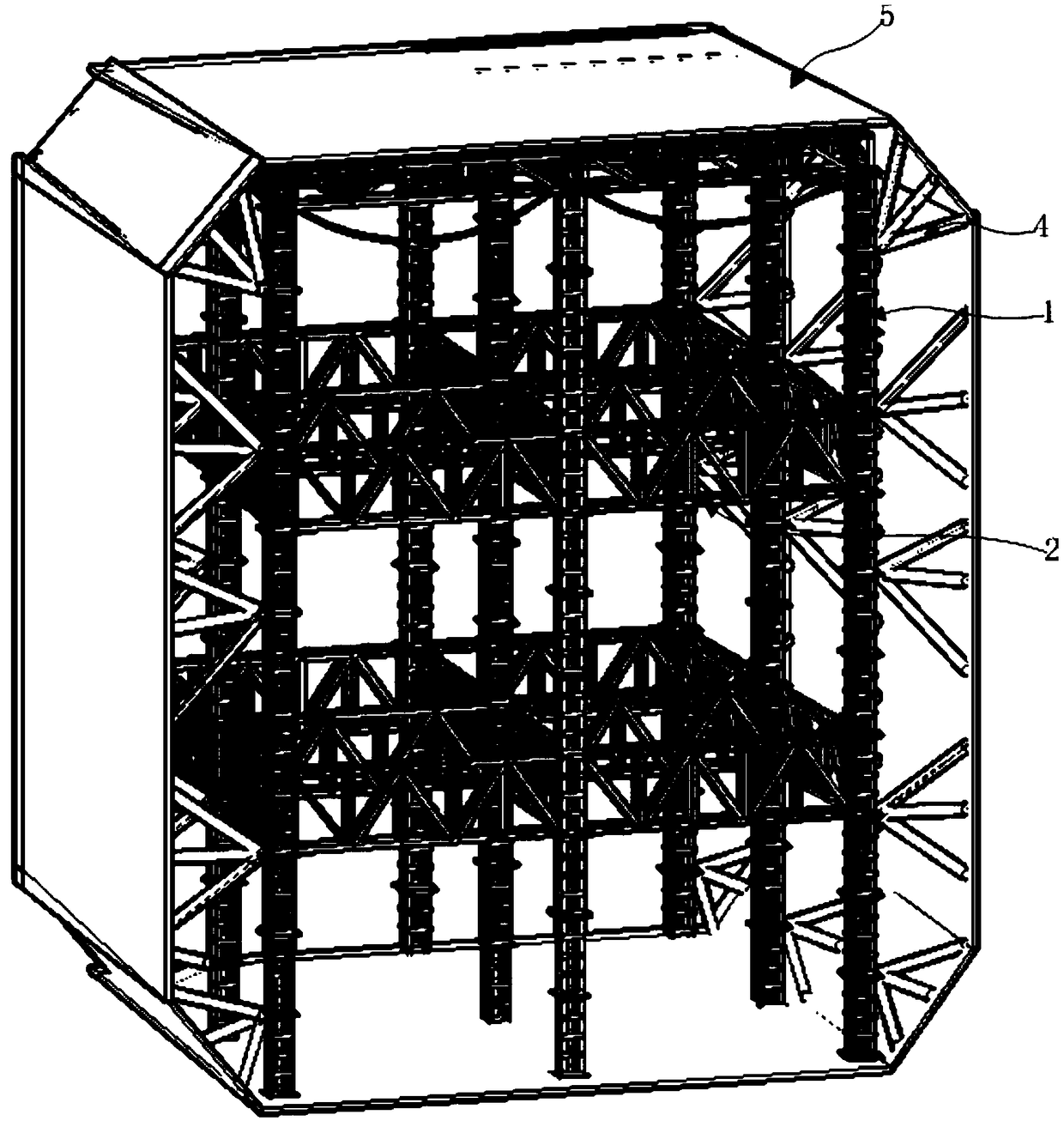

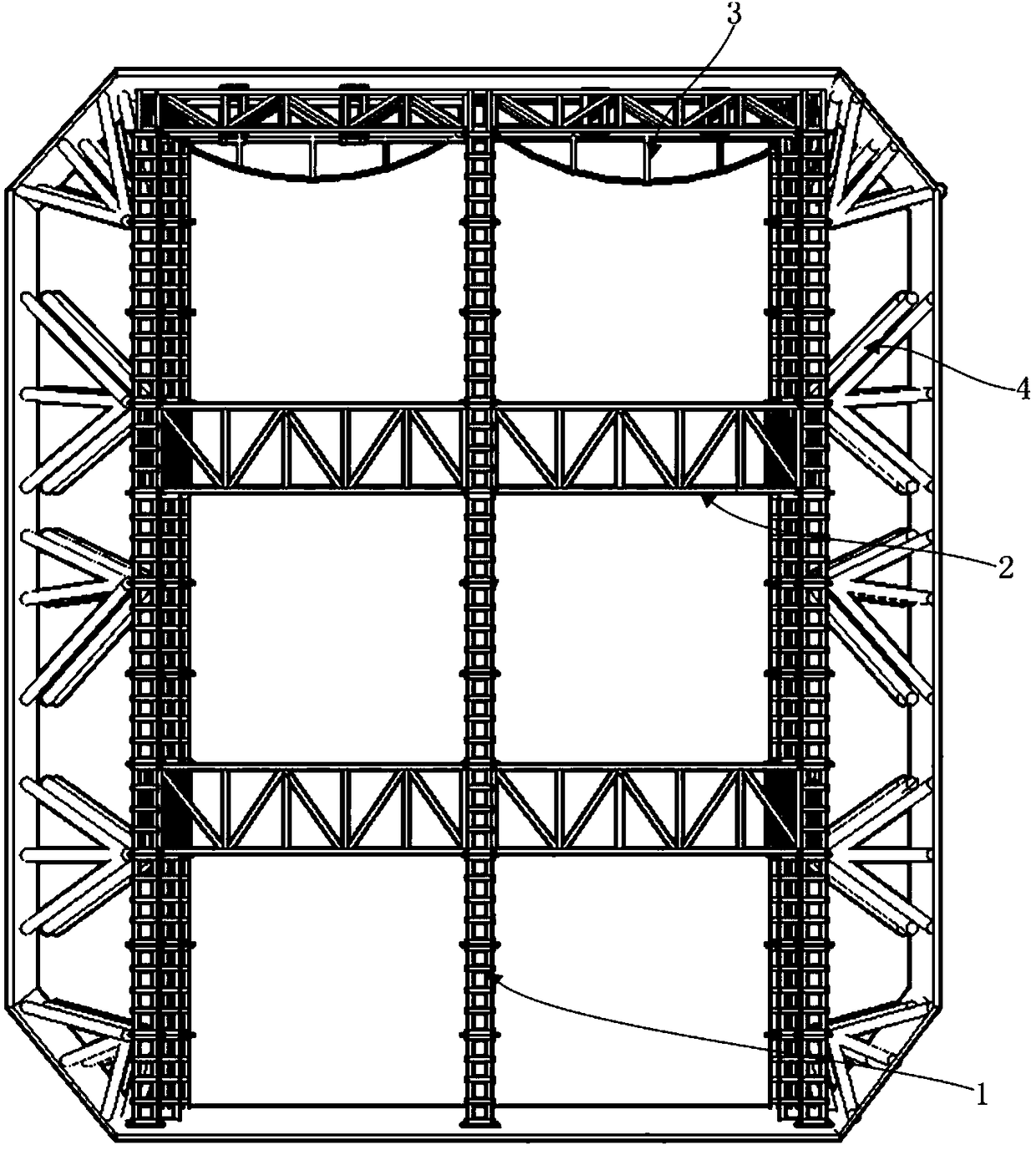

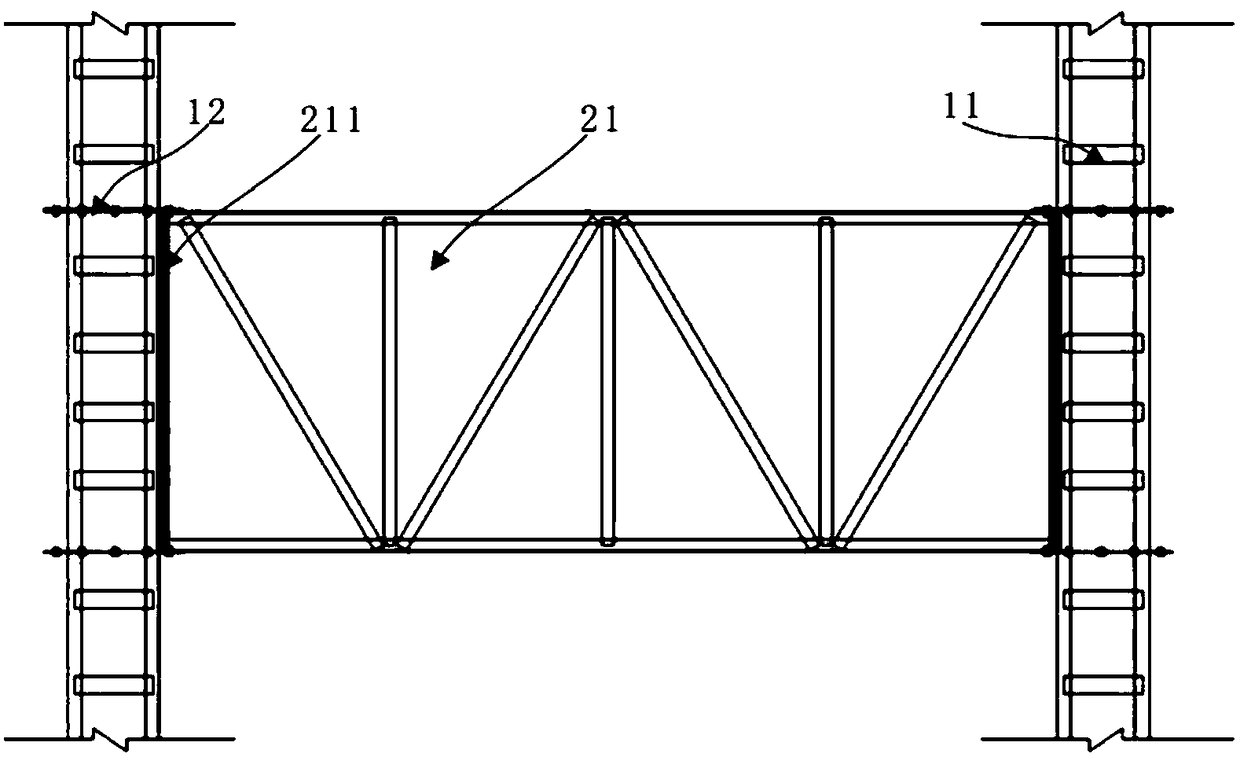

Fabricated mold plate supporting device of shaped concrete tunnel body

InactiveCN109339436ALight weightMeet the requirements of construction precision control indicatorsForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksStructural engineering

The invention discloses a fabricated mold plate supporting device of a shaped concrete tunnel body. The fabricated mold plate supporting device comprises a plurality of lattice columns, one or more layers of plane truss beams are arranged on a square columnar support composed of all lattice columns in the height direction, and the plane truss beams include a plurality of transverse truss beams fixedly connected between two adjacent lattice columns and a plurality of longitudinal truss beams connected between two adjacent and parallel transverse truss beams; tension chord truss beams are fixedly installed between the lattice columns at the edge of the top end of the columnar support, the plane truss beams are installed at the top ends of the lattice columns located in the space enclosed byall tension chord truss beams, and the plane truss beams at the top ends of the lattice columns and the tension chord truss beams are fixedly connected through the transverse truss beams and the longitudinal truss beams; and a plurality of supporting mechanisms for supporting the side faces of mold plates are arranged on the two lines of the lattice columns which are parallel to the longitudinal truss beams and located at the outermost layer in the height direction.

Owner:SOUTHWEAT UNIV OF SCI & TECH

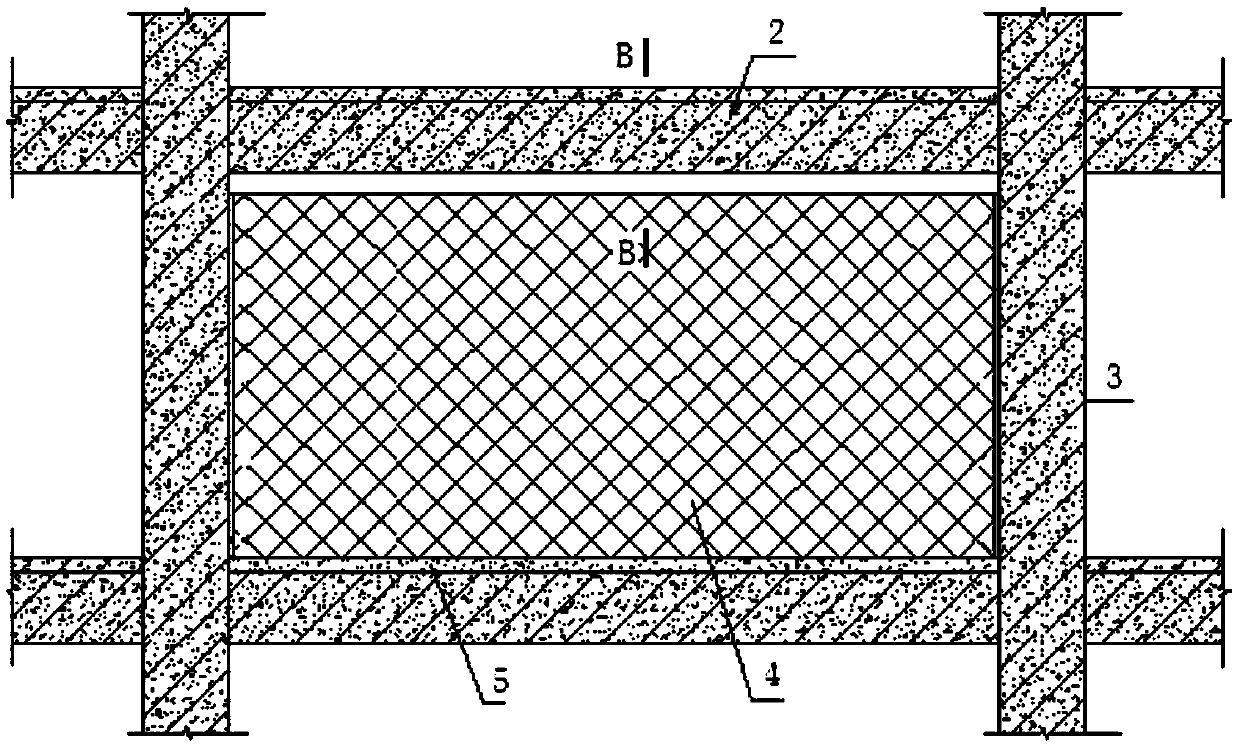

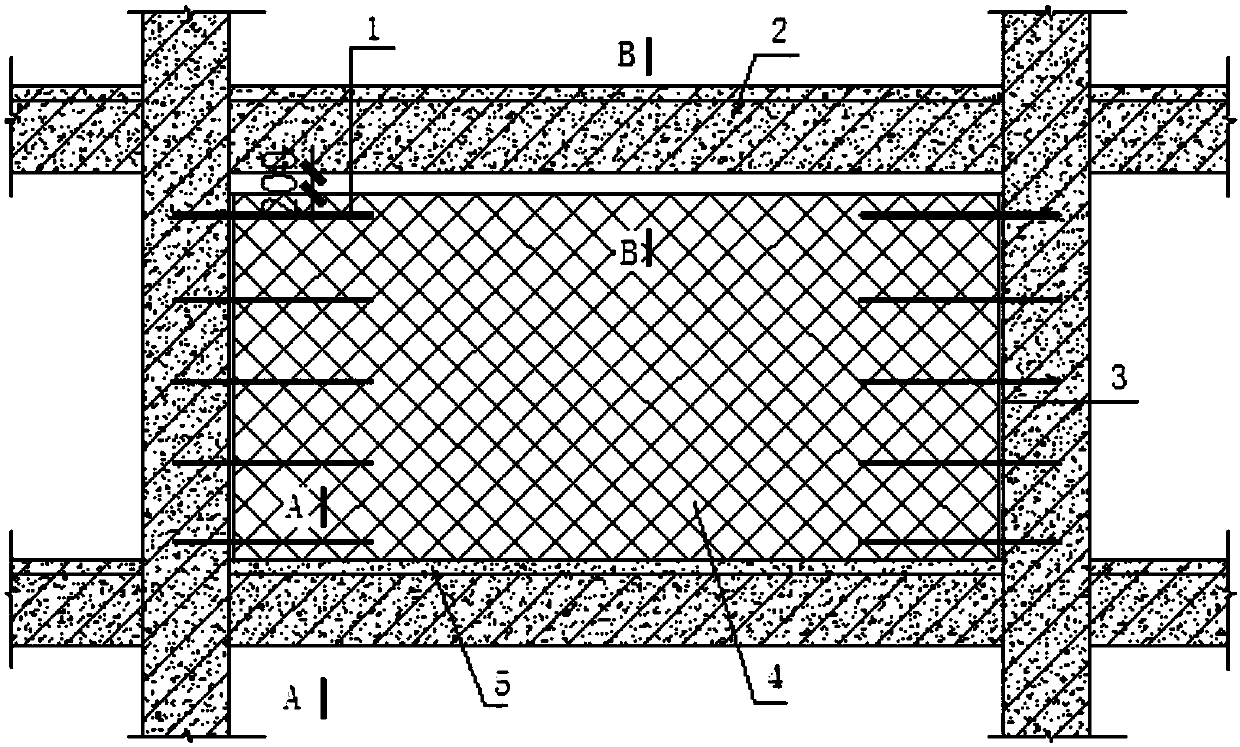

Construction method and structure system of prefabricated large plate filled wall concrete structure

InactiveCN109653404AReduce the number of seamsReduce construction costsWallsFloor slabConcrete beams

The invention discloses a construction method and a structure system of a prefabricated large plate filled wall concrete structure. The prefabricated large plate filled wall concrete structure systemcomprises a cast-in-place concrete structure and a prefabricated large plate filled wall, the cast-in-place concrete structure comprises a cast-in-place concrete column, wall and beam, and the insideof the cast-in-place concrete structure is filled with the prefabricated large plate filled wall. The construction method includes the steps: firstly, mounting the prefabricated large plate filled wall serving as a peripheral protective wall and an inner wall on a certain layer of a building once, and reserving a gap between the top of the filled wall and the bottom of the cast-in-place concrete beam; secondly, setting templates such as a main structure concrete column, a shear wall, a beam and a floor slab and binding reinforcement, taking the side face of a wall plate as part of a wall column side template and pouring main structure concrete; finally, reliably connecting the top of the filled wall with the bottom of the concrete beam to reliably connect the filled wall with a cast-in-place concrete main structure. The technical problems of low construction speed, poor quality and integrity, difficulty in hoisting and the like of a prefabricated large plate filled wall in a traditional construction mode are solved.

Owner:马杰

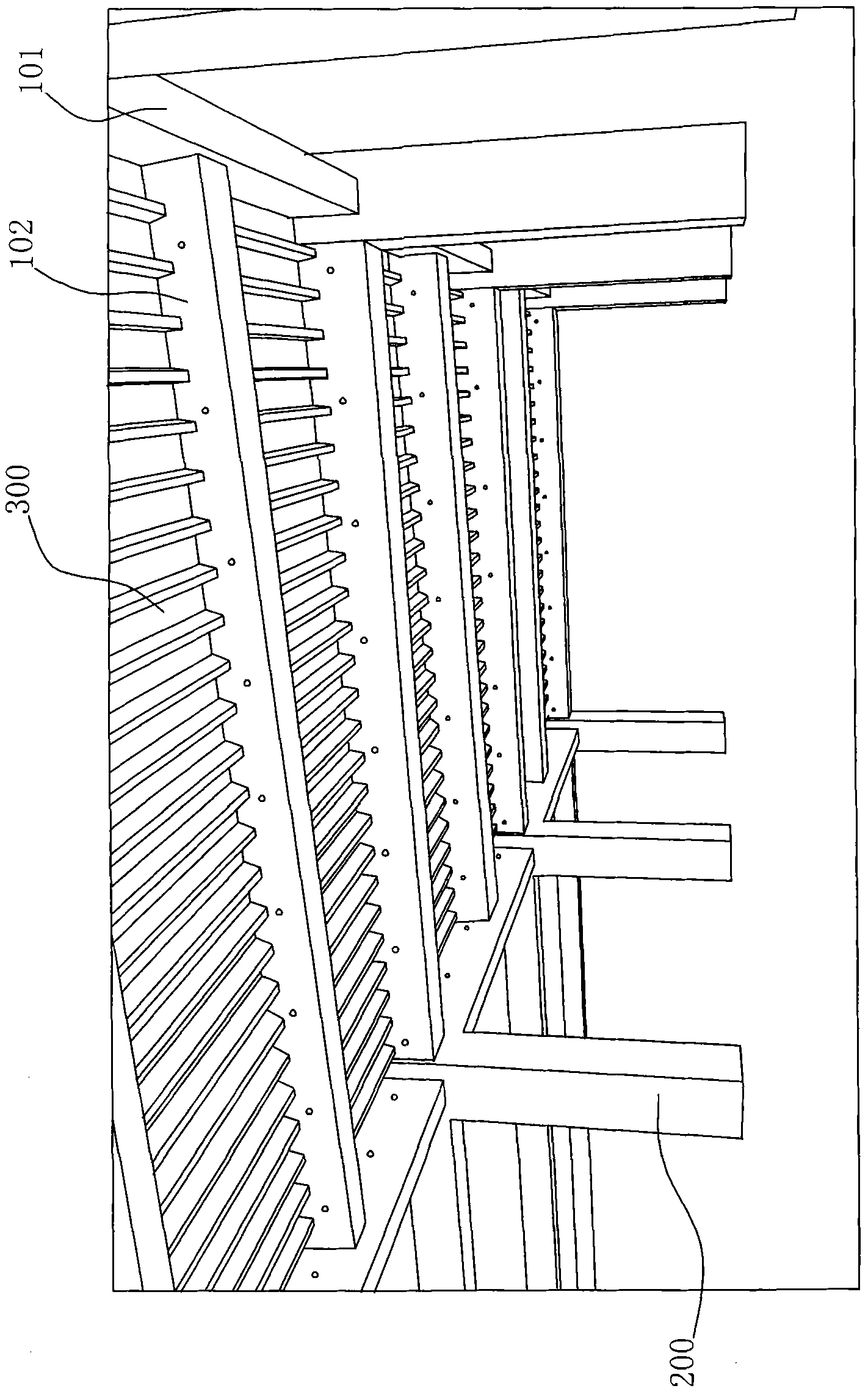

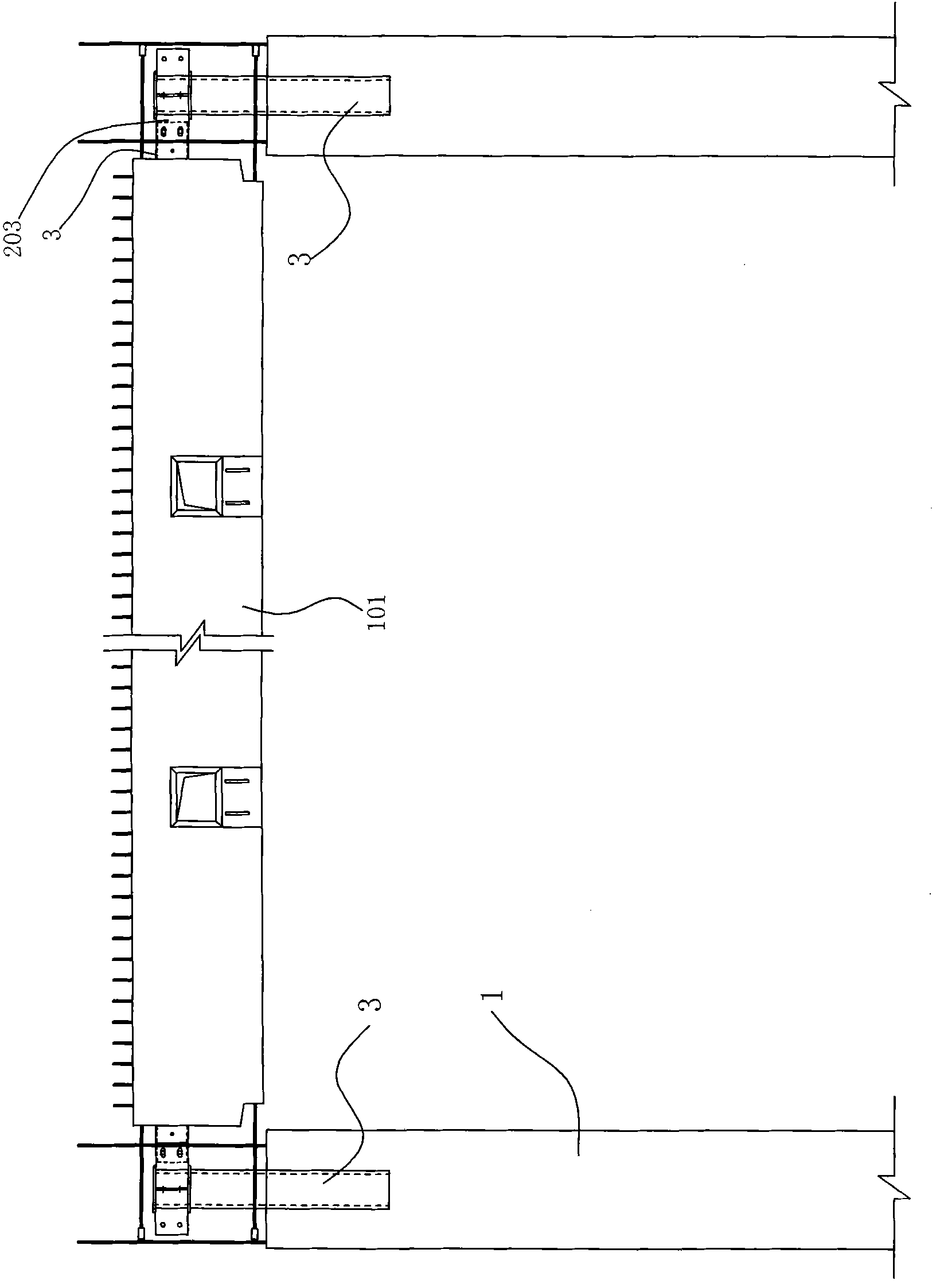

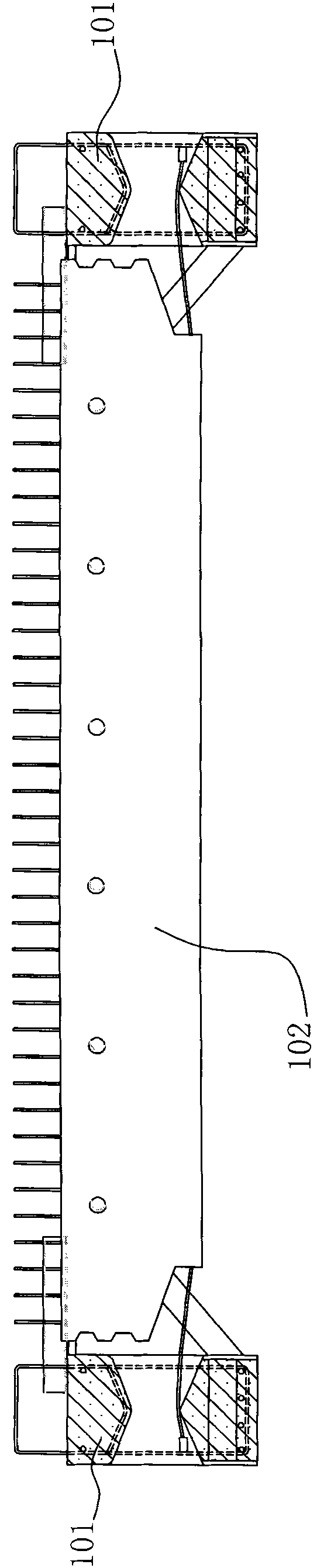

Reinforced concrete prefabricated integrally-cast building structure system and construction method thereof

ActiveCN102418386BReduce steel consumptionReduce the overall heightFloorsBuilding material handlingReinforced concreteFloor slab

The invention relates to a novel reinforced concrete prefabricated integrally-cast building structure system, which comprises a floor slab, superposed beams and columns and / or shearing walls. Each superposed beam comprises a primary beam and a secondary beam and consists of a prestressed prefabricated beam and a cast-in-situ part. The prestressed prefabricated beam comprises a beam body and prestressed steel stranded wires. Section steel is arranged at the end parts of the beam body. One part of the section steel is buried in the beam body and the other part of the section steel is exposed at the end part of the beam body. The prefabricated beam in the primary beam is connected with the columns and / or the shearing walls through the section steel. The prefabricated beam in the secondary beam is placed on the primary beam through the section steels. A plurality of template supporting holes are longitudinally arranged on the beam body of the prefabricated beam of the secondary beam and the beam body of the prefabricated beam of the primary beam in parallel with the secondary beam. By adopting the prefabricated beams to be integrally cast with the cast-in-situ beams and the cast-in-situ floor slab to form a structure system, the prefabricated beams are fabricated by adopting a pre-tensioning prestressed technique and can be produced on a large scale in plants at one time and the production cost is reduced.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

Grooved steel-concrete combination beam

The invention relates to a groove steel-concrete integration beam, belonging to the bridge support element area, which can be used in track bridge; railway bridge; and road Bridge. The invention comprises a steel box beam whose top is open, concrete filled in the inner side of steel box beam and the anti-cutting connection element welded on the inner side of steel box beam. wherein, said open steel box beam is formed by a bottom plate and a middle plate, whose sections are in U or W shape; the anti-cutting connection element can integrate the steel beam and the concrete as a whole to display the anti-compression property of concrete; the steel plate can resist the pulling stress of each direction and avoid surface breakage; and the anti-cutting connection element can transfer the shearing force between steel box beam and concrete and avoid their separation. The invention has the advantages of simple operation, application of avoiding surface breakage and wider application prospect, as well as the advantages of initial stress concrete groove beam.

Owner:TSINGHUA UNIV

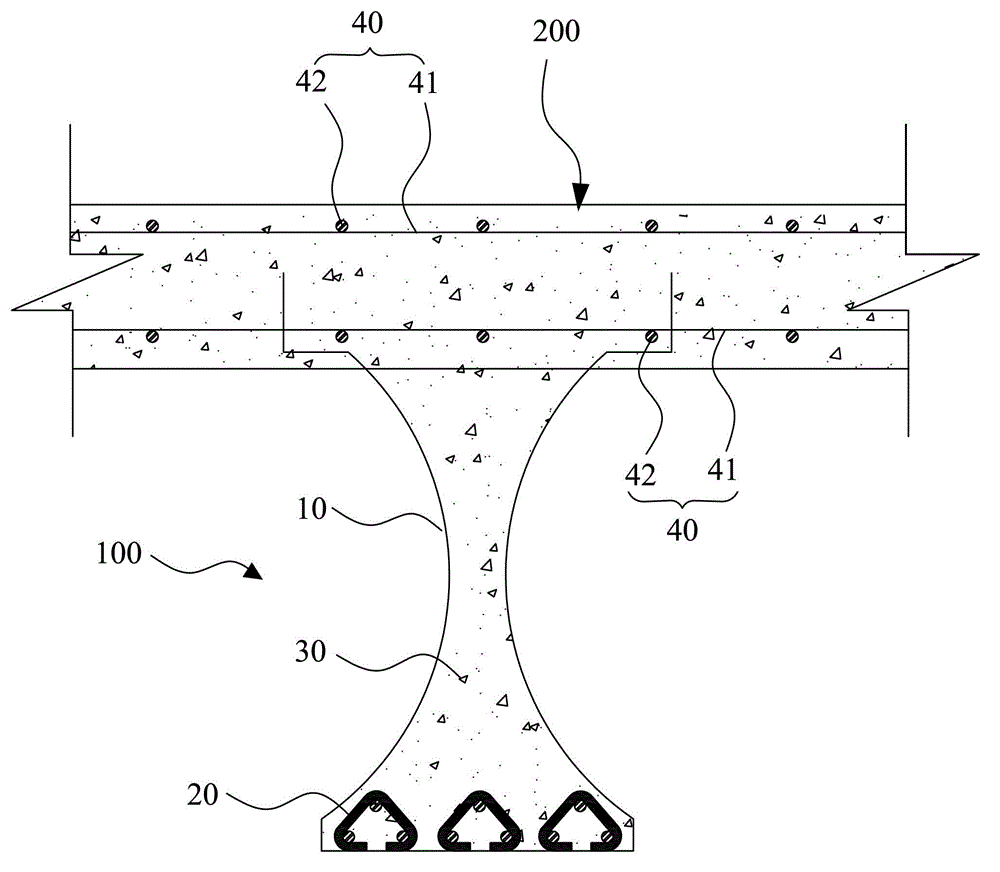

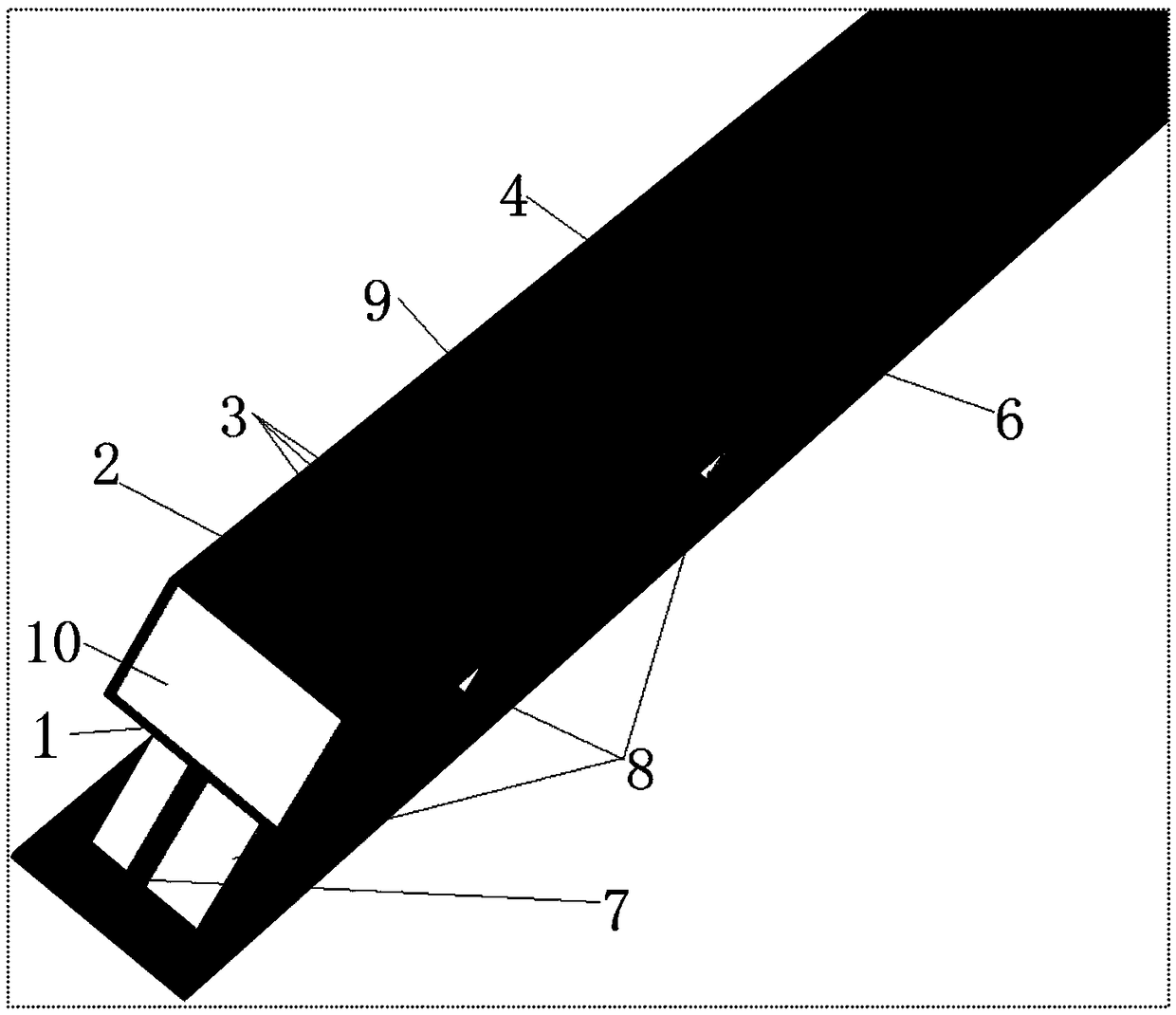

Self-supporting deformed steel-encased concrete composite beam

The invention discloses a self-supporting deformed steel-encased concrete composite beam which comprises a deformed thin-wall steel section, full-length reinforcement cages and concrete filler. The deformed thin-wall steel section comprises a lower bottom plate, webs on two sides of the lower bottom plate, and upper flanges at the upper ends of the webs. Each web is provided with a concave. The two webs, the lower bottom plate and the upper flanges enclose a deformed containing cavity. The upper end of the deformed containing cavity is provided with an opening in the thickness range of a floor covering. The full-length reinforcement cages are distributed in the deformed containing cavity and fixed on the lower bottom plate of the deformed thin-wall steel section. The concrete filler is integrally poured into an opening at the upper end of the deformed thin-wall steel section, the inner deformed containing cavity, the full-length reinforcement cages and the floor covering, so that structural bearing capacity, rigidity, cracking resistance and construction performance are increased evidently, no external concrete formwork is needed during construction, and labor reduction, construction period shortening and auxiliaries economization can be achieved.

Owner:HUAQIAO UNIVERSITY

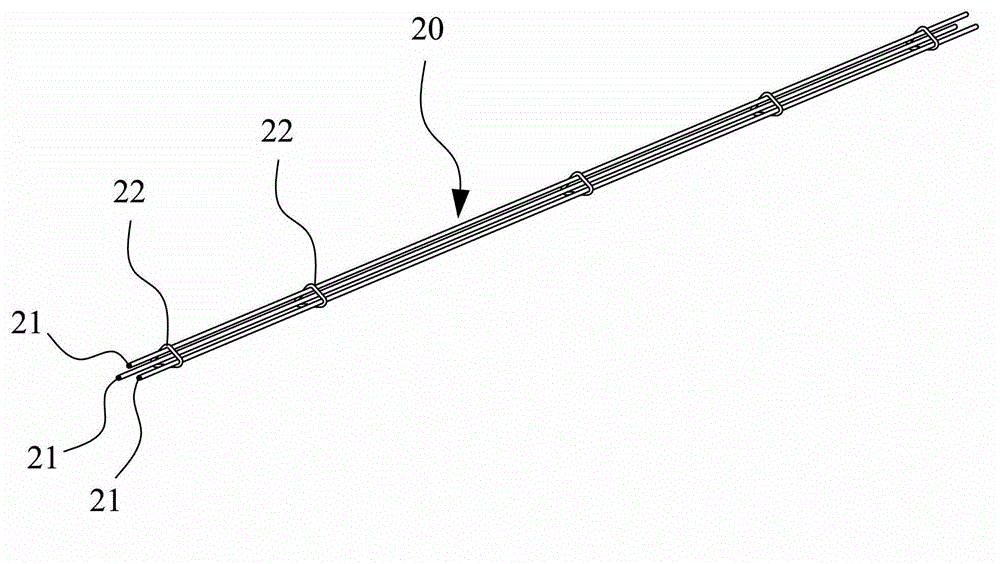

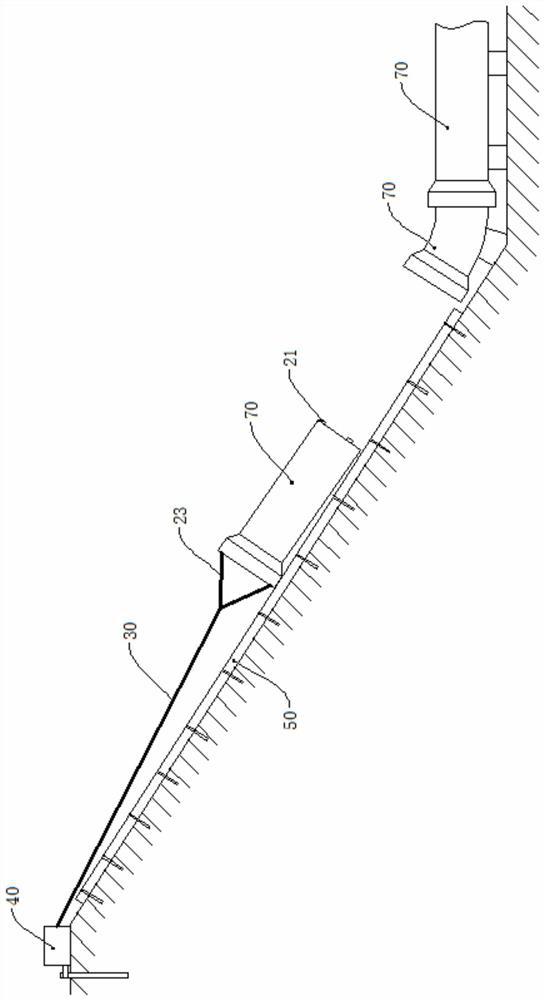

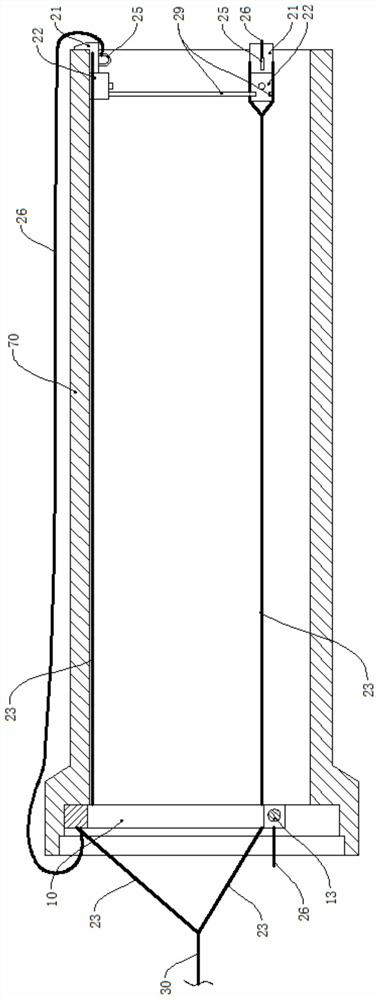

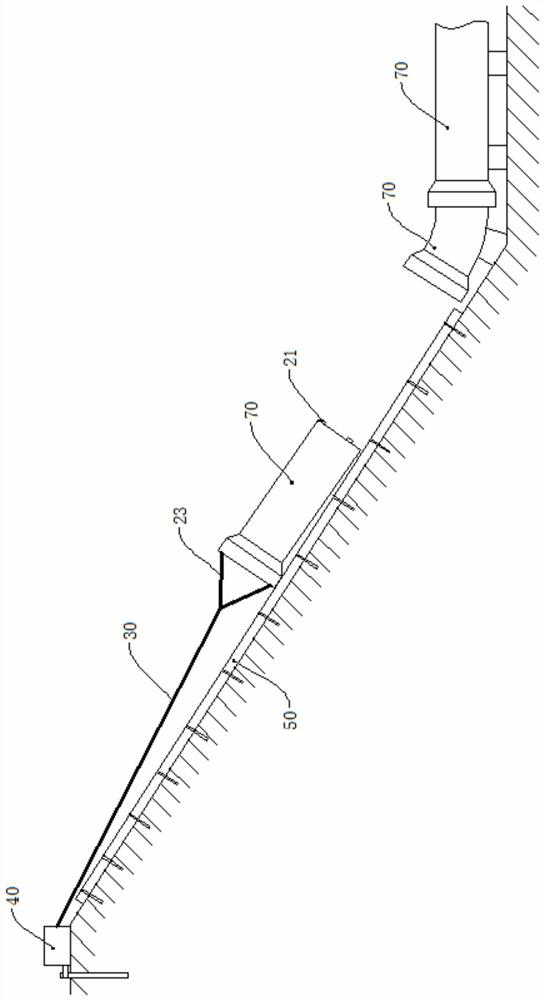

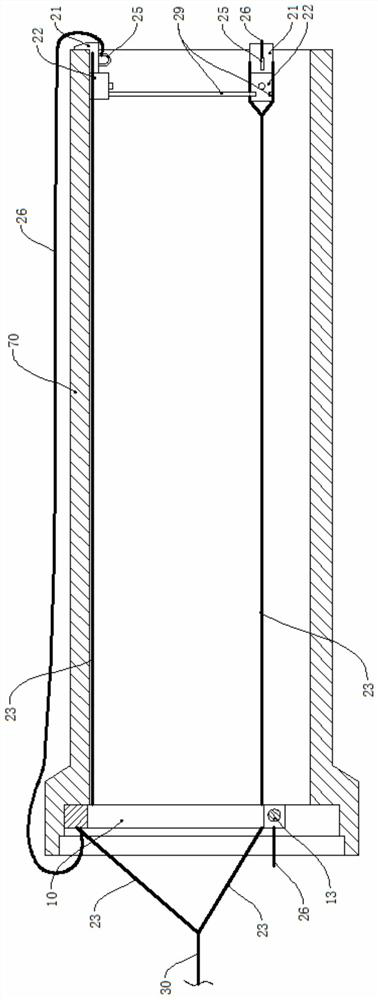

Pipe section installing device and method

ActiveCN111946900AEasy to install in placeImprove installation efficiencySleeve/socket jointsPipe laying and repairPipeGantry crane

The invention provides a pipe section installing device and method, and belongs to the technical field of pipeline construction. Through cooperation of a slide way, the pipe section fastener, a traction rope, a power mechanism and the like, a pipe section can be transported to the open position of the top of a slope, after the pipe section is fixed through the pipe section fastener, the pipe section is gradually put downwards in the preset position by the power mechanism and the traction rope through the slide way to be installed, a gantry crane is not needed in the whole installation process,and a crane does not need to be arranged on the slope; thus, the pipe section can be advantageously and conveniently installed in place, and the installing efficiency is improved; and the pipe section fastener is reversely installed between a to-be-installed pipe section and the installed pipe section, the to-be-installed pipe section is directly pressed on the installed pipe section through a jacking pressing assembly, installing of the to-be-installed pipe section is completed, operation is easy and convenient, other extra equipment is not needed any more, and the construction efficiency can be better improved.

Owner:中铁十七局集团第三工程有限公司

Wineglass-shaped section steel-concrete composite beam and construction method thereof

The invention discloses a wineglass-shaped section steel-concrete composite beam which comprises an I-shaped section steel beam. Two upper webs and two end plates in the vertical direction are weldedto the edges of the periphery around an upper flange of the I-shaped section steel beam correspondingly; an open steel box is jointly composed of the two upper webs, the two end plates and the upper surface of the upper flange; and a plurality of PBL stiffening ribs are arranged on the inner surfaces of the two upper webs and the upper surface of the upper flange in the longitudinal direction, then a plurality of pulling rods are used for cross-pulling the PBL stiffening ribs of the two upper webs at certain distances and intervals, and the open steel box is filled with concrete. The inventionfurther discloses a construction method of the wineglass-shaped section steel-concrete composite beam. Compared with a reinforced concrete beam, the self-weight of the wineglass-shaped section steel-concrete composite beam is decreased by 50% or above; compared with a traditional steel-concrete composite beam, concrete pouring is convenient, and the wineglass-shaped section steel-concrete composite beam can adapt to the larger span; and compared with the I-shaped section steel beam, the wineglass-shaped section steel-concrete composite beam is more reasonable in force bearing performance andbetter in comprehensive economic performance.

Owner:PANZHIHUA UNIV

Connecting joint structure of continuous box type crane beam and lattice type column

The invention discloses a connecting joint structure of a continuous box type crane beam and a lattice type column. The connecting joint structure comprises the continuous box type crane beam and the lattice type column, wherein the continuous box type crane beam is of a box type beam structure defined by an upper flange plate, a lower flange plate, a first web and a second web; the lattice type column comprises an upper column body and a shoulder beam body which are connected up and down; the upper flange plate and the lower flange plate are provided with an upper through hole and a lower through hole correspondingly; the upper end of the upper column body sequentially penetrates the lower through hole and the upper through hole; a support is fixedly arranged at the bottom of the lower flange plate and supported on the shoulder beam body; a supporting plate is fixedly arranged on the shoulder beam body and located on the side portion of the support; and the top of the upper column body is fixedly connected with the upper flange plate through an upper fixing assembly, the upper fixing assembly can cover the upper through hole, the bottom of the upper column body is fixedly connected with the lower flange plate through a lower fixing assembly, and the supporting plate and the lower flange plate are connected through a plurality of first fasteners. According to the connecting joint structure, connection of the continuous box type crane beam and the lattice type column can be convenient, the construction difficulty is lowered, and the construction period is shorter.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

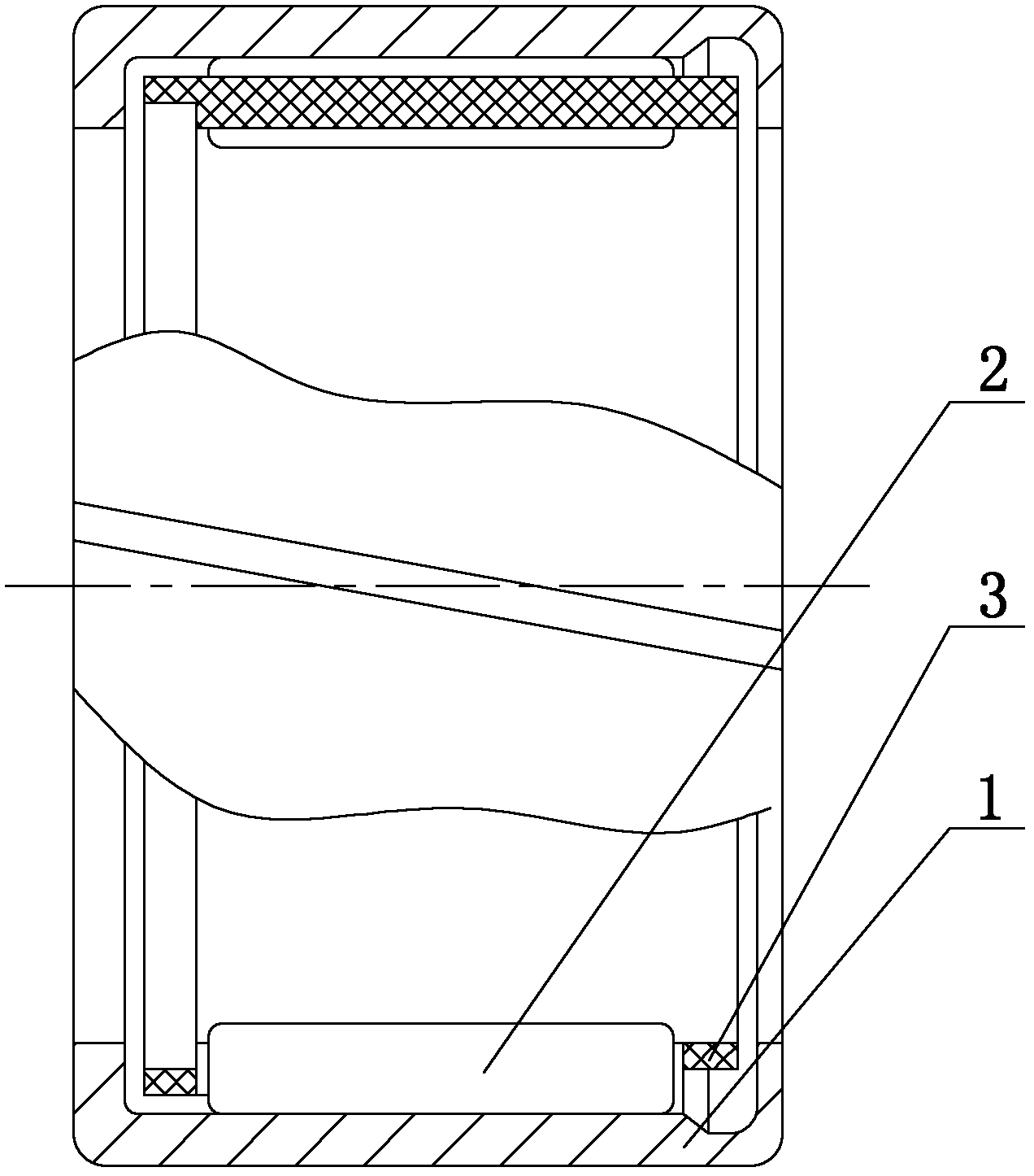

Steering engine bearing

InactiveCN103133524AHigh hardnessGuaranteed parallelismBearing componentsNeedle bearingsEngineeringMechanical engineering

The invention relates to a steering engine bearing which is provided with an outer ring and a retainer which are formed in a stamping mode. A quill roller which is fixed through the retainer is arranged on the outer ring, and the outer ring and the retainer are in a split-type structure. The outer ring of the bearing carries out automatic hemming before heat treatment, and finally carries out heat treatment quenching, so the steering engine bearing ensures parallel errors of a hemming and a reference edge, and also ensures dimensional stability.

Owner:许民强

Hoisting method of loop reactor

ActiveCN107758507BEnsure balanceEasy to install in placeLoad-engaging elementsStraight tubeEngineering

Owner:中石化重型起重运输工程有限责任公司 +1

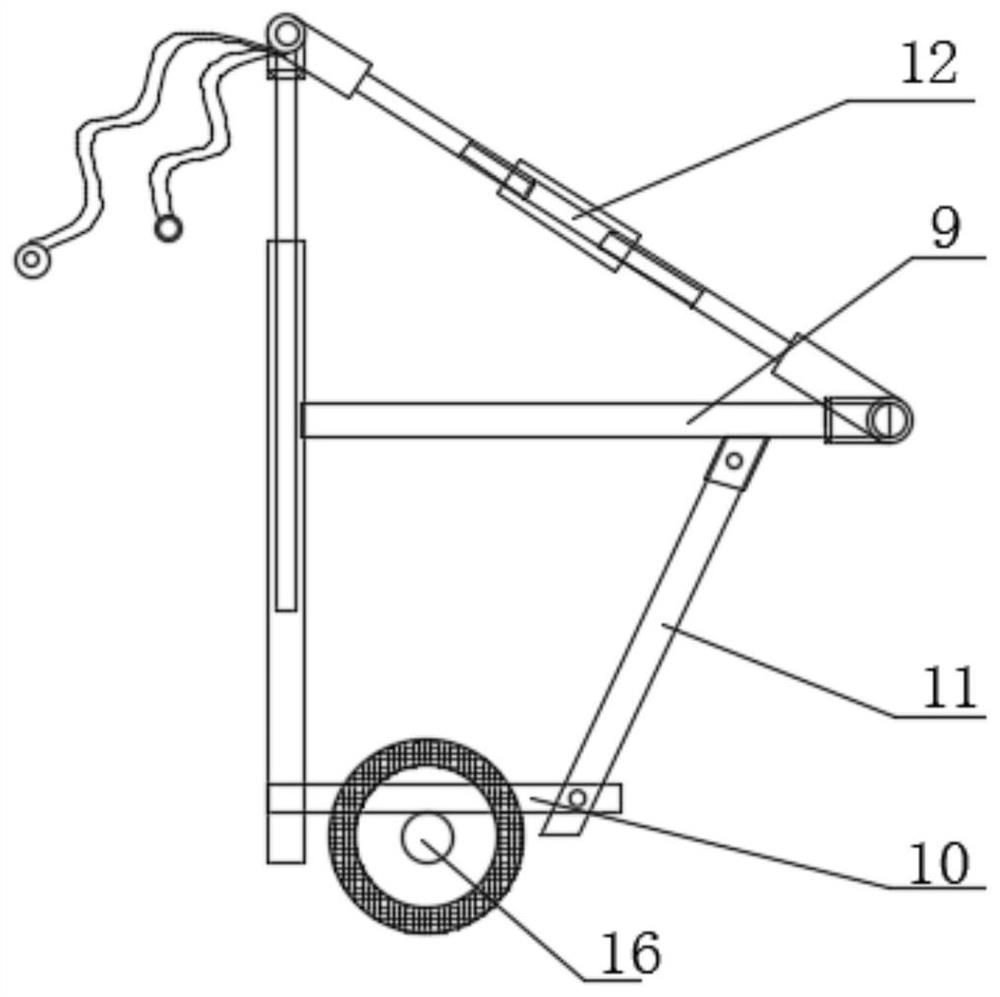

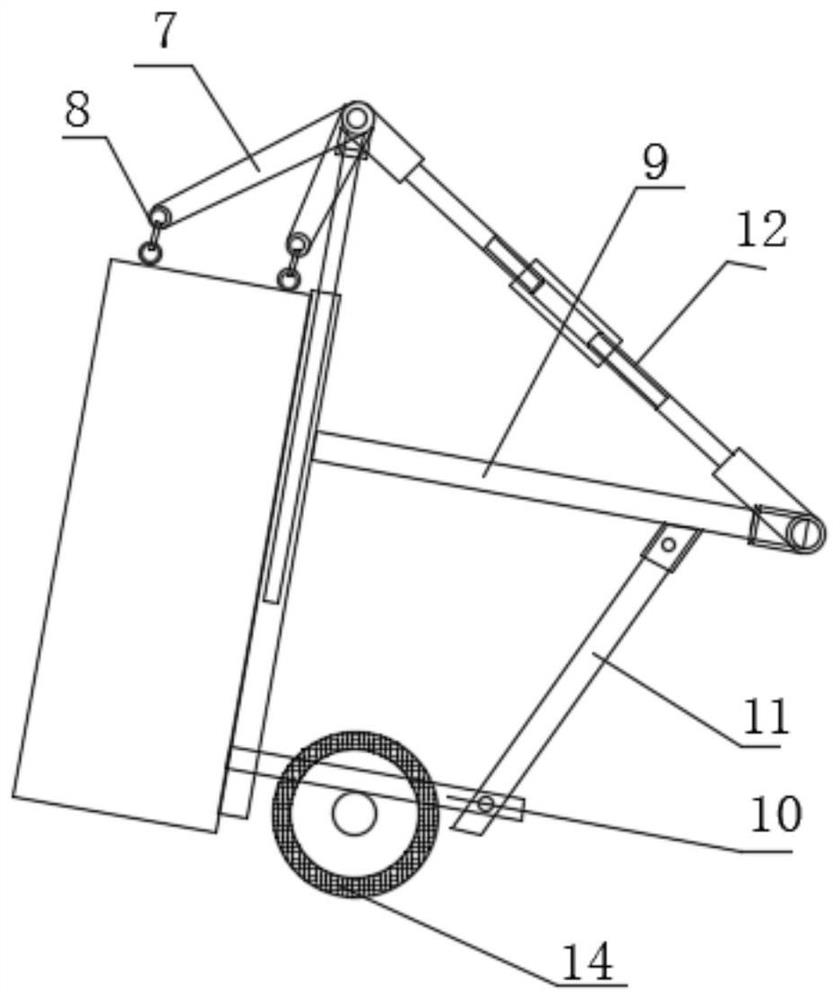

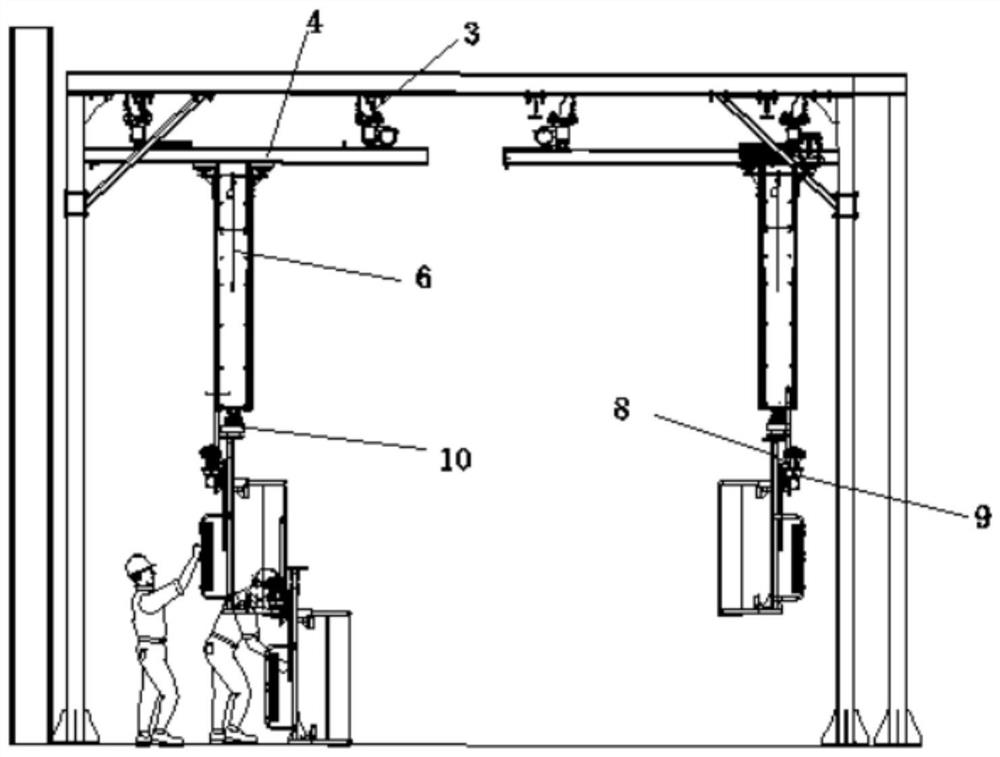

Adjustable electrical cabinet reshipment device

PendingCN113072015AFlexible handlingReduce construction costsLifting devicesLoad-engaging elementsStructural engineeringMaterial resources

The invention provides an adjustable electrical cabinet reshipment device, which comprises a cross beam including an upper cross beam and a lower cross beam; a supporting rod comprising a first supporting rod and a second supporting rod, wherein the first supporting rod is arranged on the upper cross beam, and the second supporting rod is arranged on the lower cross beam; the first supporting rod and the second supporting rod are connected through a fixed piece and are partially overlapped, and the length of the overlapped part is determined according to the height of an electrical cabinet; a connecting part movably arranged on the upper cross beam and used for connecting the electrical cabinet; a fixed rod arranged on the supporting rod and used for fixing the cross beam and the supporting rod; and a moving part arranged on the fixed rod and used for moving the whole device. The adjustable electrical cabinet reshipment device provided by the invention has the beneficial effects that the electrical cabinet is convenient to install in place, the installation construction time is shortened, manpower and material resources are saved, the appearance and internal electrical facilities of the electrical cabinet can be well protected, meanwhile, the electrical cabinet capable of being matched, moved and installed in place is wide in size, and the moving cost is reduced.

Owner:MCC TIANGONG GROUP

Pipe joint installation device and method

ActiveCN111946900BEasy to install in placeImprove installation efficiencySleeve/socket jointsPipe laying and repairPipeGantry crane

The invention provides a pipe joint installation device and method, belonging to the technical field of pipeline construction. The present invention can transport the pipe joint to the open position on the top of the slope through the cooperation of slideways, pipe joint fasteners, traction ropes and power mechanisms. After the pipe joints are fixed by pipe joint fasteners, the power mechanism and traction rope are used The pipe joint is gradually lowered to the preset position through the slideway for installation. The whole installation process does not require the use of a gantry crane, nor does it need to deploy a crane on the hillside, which is conducive to the convenient installation of the pipe joint in place and improves the installation efficiency; and the pipe joint buckle is used. The fittings are reversely installed between the pipe joints to be installed and the installed pipe joints, and the pipe joints to be installed are directly pressed against the installed pipe joints through the top pressure component to complete the installation of the pipe joints to be installed. The operation is simple and convenient, and it is not necessary Additional other equipment is needed, which is conducive to improving construction efficiency.

Owner:中铁十七局集团第三工程有限公司

A prefabricated wallboard production line

ActiveCN111618917BEfficient productionOvercome the problem of low production efficiencyMetal working apparatusMetal-working hand toolsThermal insulationManufacturing line

This paper discloses an assembled wall panel production line, comprising: an assembly platform, the upper end of which is provided with an assembly plane; a keel feeding mechanism, which is arranged on one side of the assembly platform; a wall panel Feeding mechanism, the wall panel feeding mechanism is arranged on the other side of the assembly platform relative to the keel feeding mechanism; thermal insulation material feeding mechanism, the thermal insulation material feeding mechanism is connected to the assembly platform; A nailing mechanism, the nailing mechanism is arranged on the assembly platform; an automatic grabbing mechanism, the automatic grabbing mechanism is arranged on both sides of the assembly platform corresponding to the keel feeding mechanism and the wall panel feeding mechanism side. This article relates to the field of prefabricated wall production. It provides a prefabricated wall panel production line, which can overcome the problem of low production efficiency. It forms a large-scale production, which can efficiently and quickly produce prefabricated wall panels. At the same time, the production quality can also be improved. Guaranteed.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Preparation method of fabricated wall body

ActiveCN111622384AEfficient productionSolve efficiency problemsWallsEngineeringMechanical engineering

The invention discloses a preparation method of a fabricated wall body, and relates to the field of fabricated wall body production. The preparation method includes the following steps of (1), keel feeding; (2), heat insulating material feeding; (3), wall panel feeding; (4), nailing fixing; and (5), site combining. The fabricated wall body is obtained. According to the preparation method of the fabricated wall body, the problem that the production efficiency is low can be solved, the problems of low efficiency, construction pollution and the like during traditional wall body construction are solved, the fabricated wall body can be efficiently and rapidly produced, and meanwhile the construction quality can be guaranteed.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Power-assisted manipulator for passenger car tire installation

The invention discloses a power-assisted manipulator for passenger car tire installation, which comprises a cross beam and longitudinal beams, a walking trolley I is arranged below the cross beam, the longitudinal beams are connected below the walking trolley I, a walking trolley II is arranged between the longitudinal beams, a vertical sliding rail frame is connected below the walking trolley II, a guide rail matched with the sliding rail frame is arranged on the sliding rail frame. A first air cylinder is arranged on the side edge of the sliding rail frame, the bottom end of the guide rail is connected with a supporting device through a rotating device, and a clamping device is arranged on the supporting device. By means of the manipulator, a tire can be placed on the sleeve, the tire can be lifted upwards to an installation position below a passenger car through the air cylinder, then through adjustment of the mechanical arm, installation work can be greatly facilitated, the working efficiency is improved, the labor intensity is reduced, meanwhile, safety is improved, and the remarkable using effect is achieved.

Owner:CHERY & WANDA GUIZHOU BUS

Fixing of t-shaped anchor bolts and sleeve sealing method

The invention relates to a method for fixation of a T-shaped foundation bolt and sleeve sealing. The method is characterized in that first the T-shaped foundation bolt is placed in a sleeve, an annular steel plate is welded to an inner wall of the sleeve, a chain block is utilized to rotate and lift the T-shaped foundation bolt, a circular ring is sleeved with the T-shaped foundation bolt, two semi-circular steel plates are placed on the circular ring and fastened through bolts and nuts, and the circular ring is a rubber and plastic sponge circular ring. The T-shaped foundation bolt can be lifted, rotated and fixed in advance, the sleeve is effectively sealed, adjustment of the T-shaped bolt is not influenced, device installation in position is facilitated, constructors are effectively reduced, device installing efficiency is improved, and a grouting material is prevented from flowing into the sleeve.

Owner:CHINA MCC20 GRP CORP

Connecting structure and connecting method of skeleton type exterior enclosure wall and main body

PendingCN108222335AImprove the state of stressImprove the accuracy of embeddingWallsBuilding construction

The invention discloses a connecting structure and a connecting method of a skeleton type exterior enclosure wall and a body. The connecting structure includes skeleton vertical columns, support seatthrough connecting pieces and built-in fittings, the built-in fittings are pre-buried in main body floors, and connecting lug plates of the built-in fittings are located outside the body. One ends ofthe support seat through connecting pieces are in rigid connection with the skeleton vertical columns, and the other ends of the support seat through connecting pieces are fixedly connected with the connecting lug plates. A vertical column support seat connecting method with the advantages of reliable force transferring, simple structure and convenient construction is provided for an exterior enclosure system of a prefabricated building through the improvement of the connecting design of support seat joints of the skeleton vertical columns.

Owner:厦门华旸建筑工程设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com