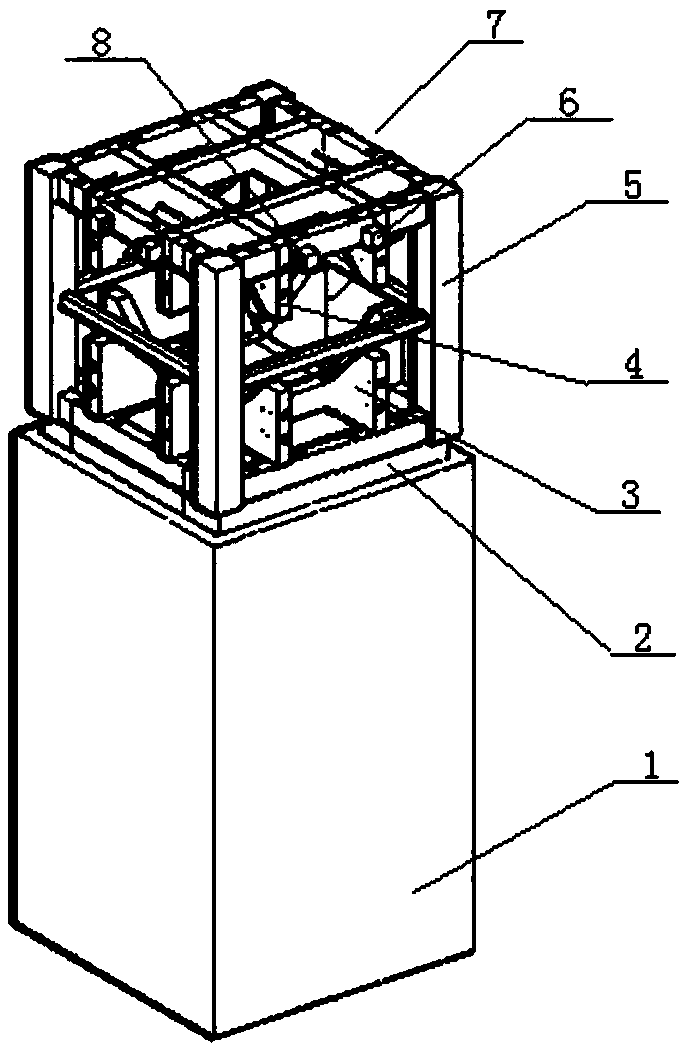

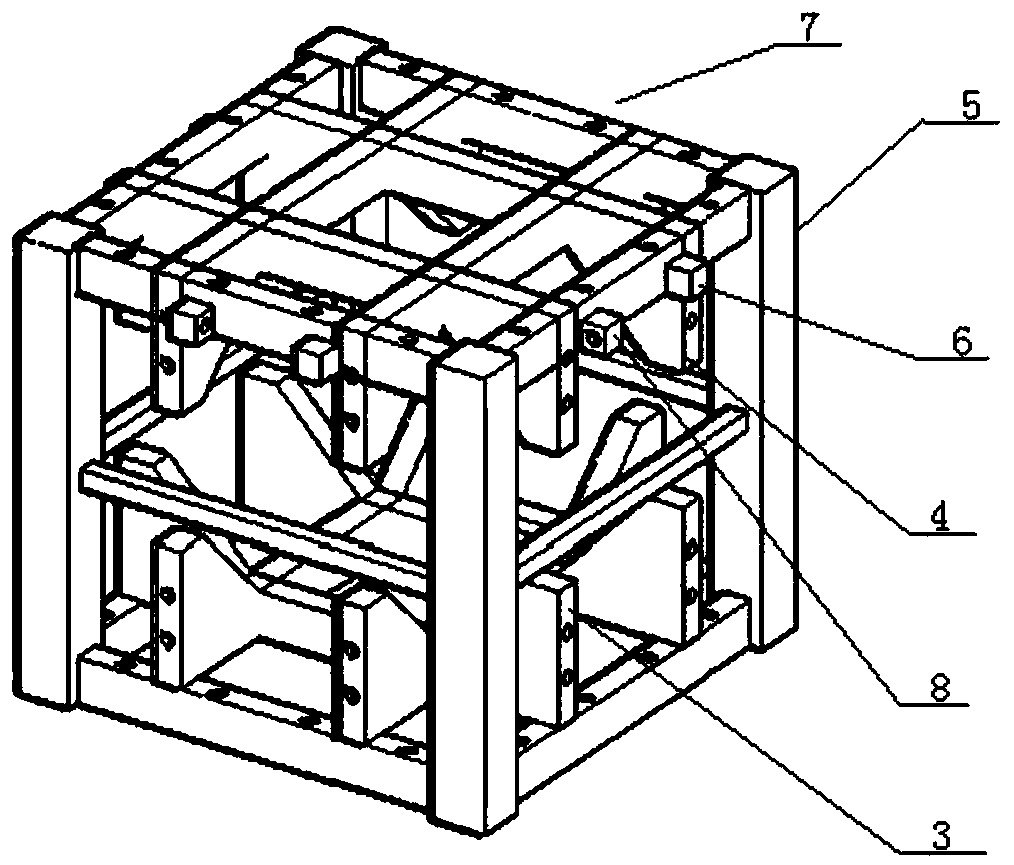

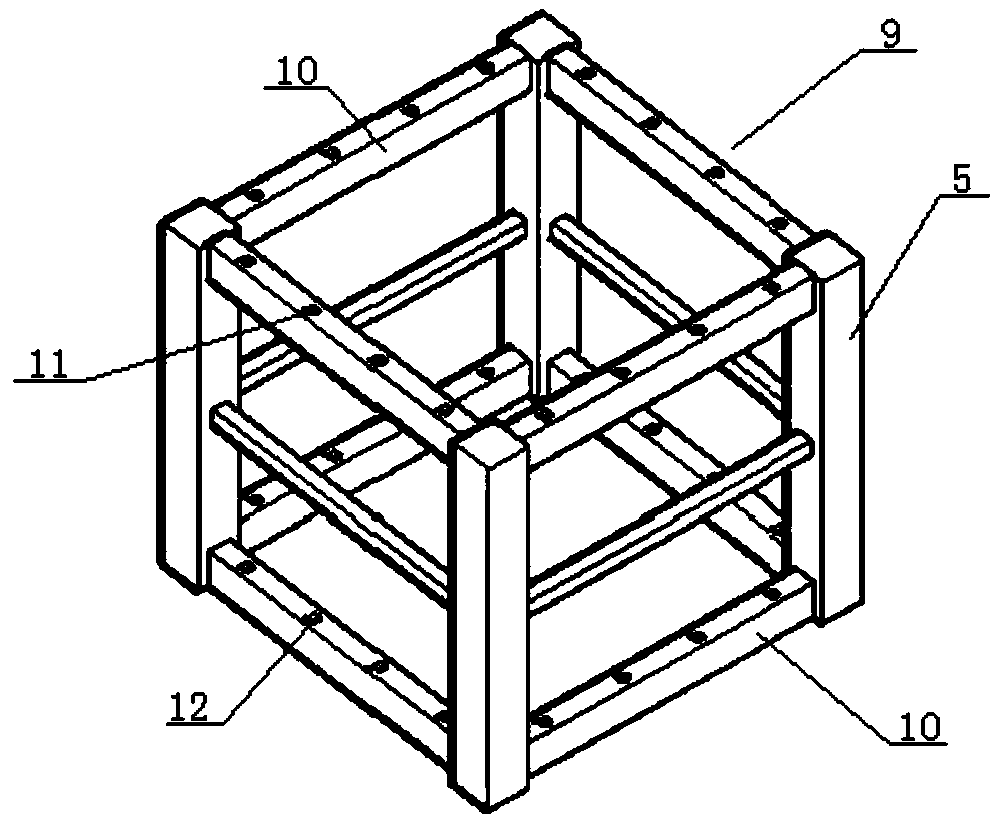

Dry-type beam column connection structure for prefabricated reinforced concrete buildings

A technology of reinforced concrete, beam-column connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

[0083] Embodiment 5, this embodiment 5 is used for the connection of the beam-column joints of the prefabricated reinforced concrete building, which is basically the same as the embodiment 2, the difference is: the pre-embedded upper column 13 and the lower column 1 of this embodiment The pre-embedded frames all adopt the second frame 16.

Embodiment 6

[0084] Embodiment 6, this embodiment 6 is used for the connection of the beam-column joints of the prefabricated reinforced concrete building, which is basically the same as the embodiment 2, except that the pre-embedded upper column 13 and the lower column 1 of this embodiment The pre-embedded frames all adopt the first frame 2.

Embodiment 7

[0085] Embodiment 7, this embodiment 7 is used for the connection of the beam-column joints of the prefabricated reinforced concrete building, which is basically the same as the embodiment 2, except that the nodes of this embodiment connect three beams 18 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com