Pipe joint installation device and method

A technology for installing devices and pipe joints, which is applied in the directions of pipeline laying and maintenance, pipe/pipe joint/pipe fitting, sleeve/socket connection, etc. Simple and convenient, the effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

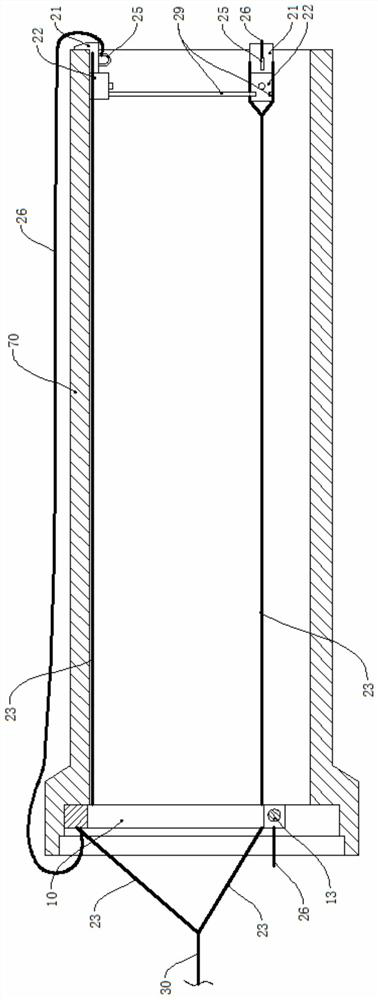

[0067] As a specific implementation of the pipe joint installation method provided by the present invention, the step of fixing the magnetic body 22 and the claw 21 on the installed pipe joint also includes:

[0068] A detachable snap ring 60 abutting against the socket end of the installed pipe joint is preset outside the installed pipe joint, the claw 21 is clamped on the snap ring 60, and the magnetic body 22 is adsorbed on the socket end of the installed pipe joint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com