A prefabricated wallboard production line

An assembly and production line technology, applied in hand-held tools, metal processing equipment, metal processing, etc., can solve problems such as low production efficiency, achieve production quality assurance, improve production continuity, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The above-mentioned preparation method can be prepared by the automatic production of the above-mentioned assembled wallboard production line, which specifically includes the following steps. First, before step (1), manually check the keel 101 used, and remove the keel 101 with defects. Then, the keel 101 is manually Loaded into the material bin 401 at the manual feeding end 403, the keel conveyor 402 can drive the material bin 401 to move to the automatic feeding end 404 after the keel 101 is in place, that is, it is on the side of the first robot 501, and then Carry out step (1); in step (1), the above-mentioned first robot 501 grabs the keel 101 in the feed bin 401, locates and places it on the assembly platform 200, and assembles the keel frame 105, and there is glass wool filled between the keels 101 The gap 106 is ready for step (2).

[0061] In step (2), the uncoiling device 301 removes the package and rolls out the rolled glass wool. After unfolding, it needs to...

Embodiment 2

[0068] see Figure 9 and Figure 10 Shown is the assembled wall panel production line of the second embodiment.

[0069] Specifically, such as Figure 9 and Figure 10 As shown, in order to prevent the splicing of the next keel frame 105 after the keel 101 in the feed bin 401 is grabbed, the side of the first robot 501 is also provided with an auxiliary feed bin 405, and the auxiliary feed bin 405 is located in the first robot 501 within the grabbing range, it can supplement the keel 101 in the keel bunker 401. After the step (1), the first robot 501 can grab a preset number of keels 101 from the silo 401 into the auxiliary silo 405 , and then the keel silo 401 returns to the manual loading end 403 to fill the keels 101 .

Embodiment 3

[0071] see Figure 11 to Figure 14 Shown is the assembled wall panel production line of the third embodiment.

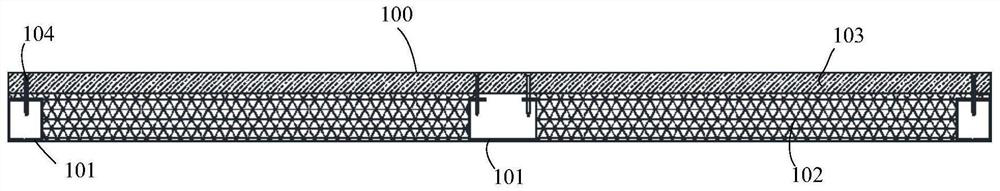

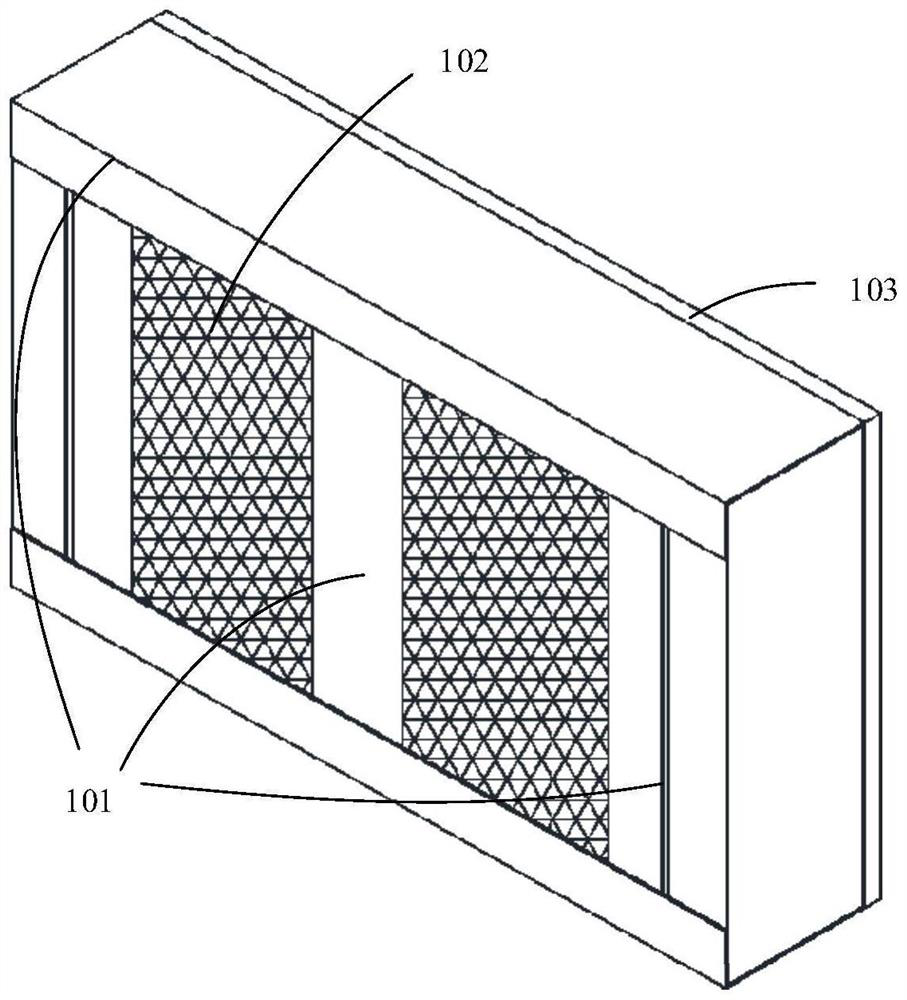

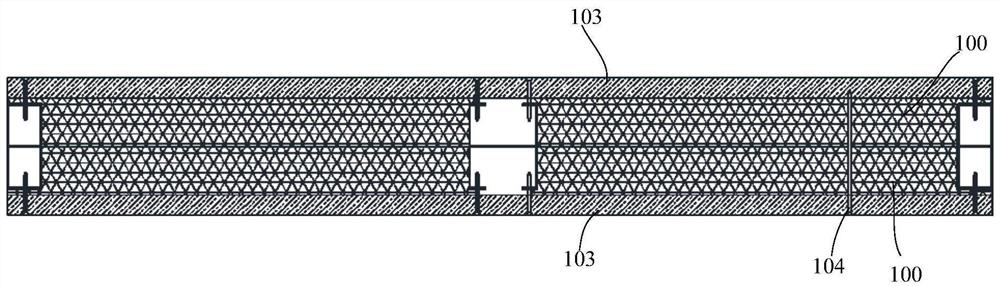

[0072] Specifically, such as Figure 11 and Figure 12As shown, due to the different heights of the keels 101 on the left and right sides of the prefabricated wall panel 100, a gap 107 is provided on one side of the prefabricated wall panel 100. When the prefabricated wall panel 100 is placed on a horizontal plane, it will be inclined. Not to mention palletizing.

[0073] In order to avoid the above-mentioned problems, during the stacking process of the assembled wall panels 100, a spacer 108 is added between two adjacent assembled wall panels 100, and the spacer 108 is located in the gap 107, so that the assembled wall panels 100 can be set horizontally, which can Stacking on the unloading turntable 800 also facilitates the transfer of forklifts.

[0074] The assembled wall panel production line also includes a pad feeding mechanism 900, which is arranged on one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com