Fixing of t-shaped anchor bolts and sleeve sealing method

A foundation bolt and sleeve sealing technology, which is applied to the frame of the engine, supporting machines, mechanical equipment, etc., can solve the problems of difficult lifting and rotation of bolts, limited working space, and incomplete sealing, so as to facilitate the installation of equipment in place, Reduce construction materials, use strong and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

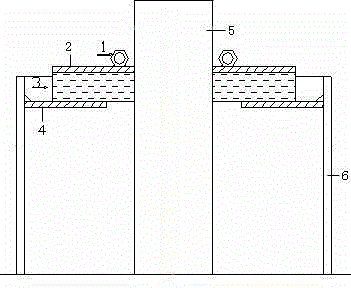

[0011] Such as figure 1 Shown: a method for fixing T-shaped anchor bolts and sealing the sleeve. First, put the T-shaped anchor bolt 5 into the sleeve, and weld the 6mm-thick circular steel plate 4 to the inner wall of the sleeve 6. The distance from the sleeve 6 is At the 30mm place on the plane, rotate and lift the T-shaped anchor bolt 5 by using the reverse chain, then put the 20mm thick rubber and plastic sponge ring 3 into the T-shaped anchor bolt 5, and place the two semi-circular steel plates 2 with a thickness of 6mm On the ring 3, use bolts to fasten through M16 nuts 1. This method can be used to lift, rotate and fix the T-shaped anchor bolts in advance, and effectively seal the sleeve without affecting the adjustment of the T-shaped bolts, which facilitates the installation of equipment in place, effectively reduces construction personnel, improves equipment installation efficiency, and prevents grouting The material flows into the sleeve. The method can greatly re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com