Connecting joint structure of continuous box type crane beam and lattice type column

A technology for connecting nodes and crane girders, which is applied to building structures and buildings, and can solve problems such as complex connection structures, difficult construction, and long construction periods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

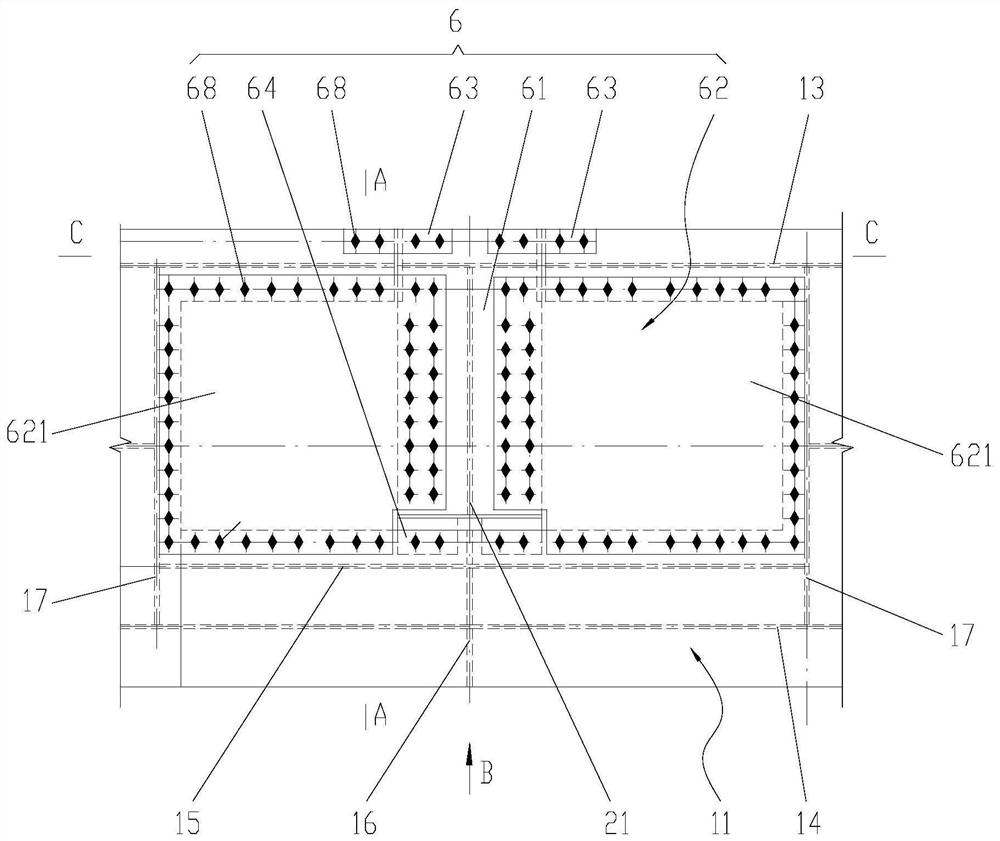

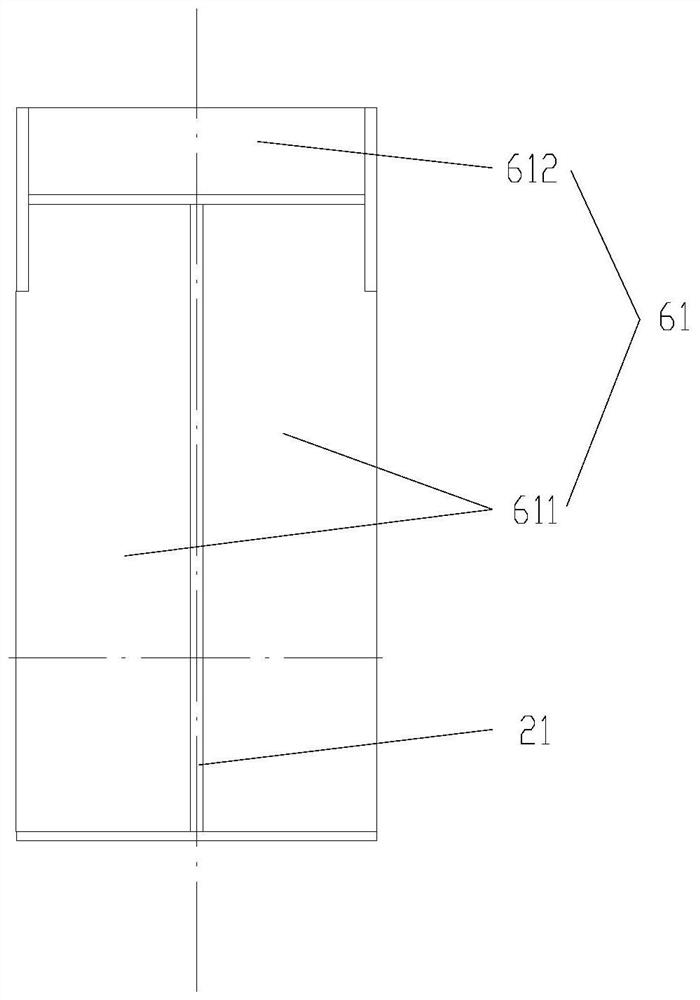

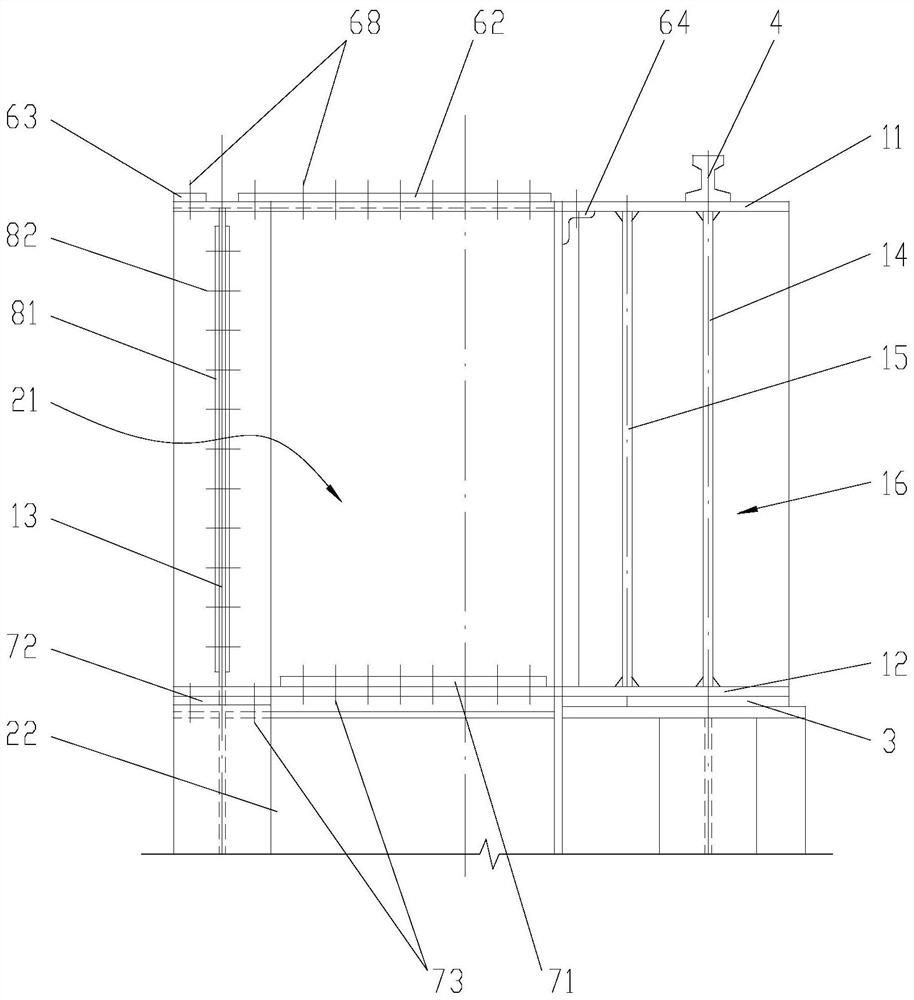

[0060] Such as Figure 1 to Figure 24 As shown, this embodiment provides a connection node structure between a continuous box crane beam and a lattice column, including a continuous box crane beam 10 and a lattice column 20, and the continuous box crane beam 10 is formed by an upper flange plate 11. A box beam structure enclosed by the lower flange plate 12 , the first web 13 and the second web 14 , and the lattice column 20 includes an upper column 21 and a shoulder beam 22 connected up and down. An upper through hole 111 and a lower through hole 121 are respectively opened on the upper flange plate 11 and the lower flange plate 12 , and the upper end of the upper column 21 passes through the lower through hole 121 and the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com