Construction method and structure system of prefabricated large plate filled wall concrete structure

A concrete structure and construction method technology, applied to walls, building components, building structures, etc., can solve the problems of high construction cost, poor integrity, damage, etc., to facilitate hoisting and transportation, reduce the risk of cracking, and reduce the number of seams Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

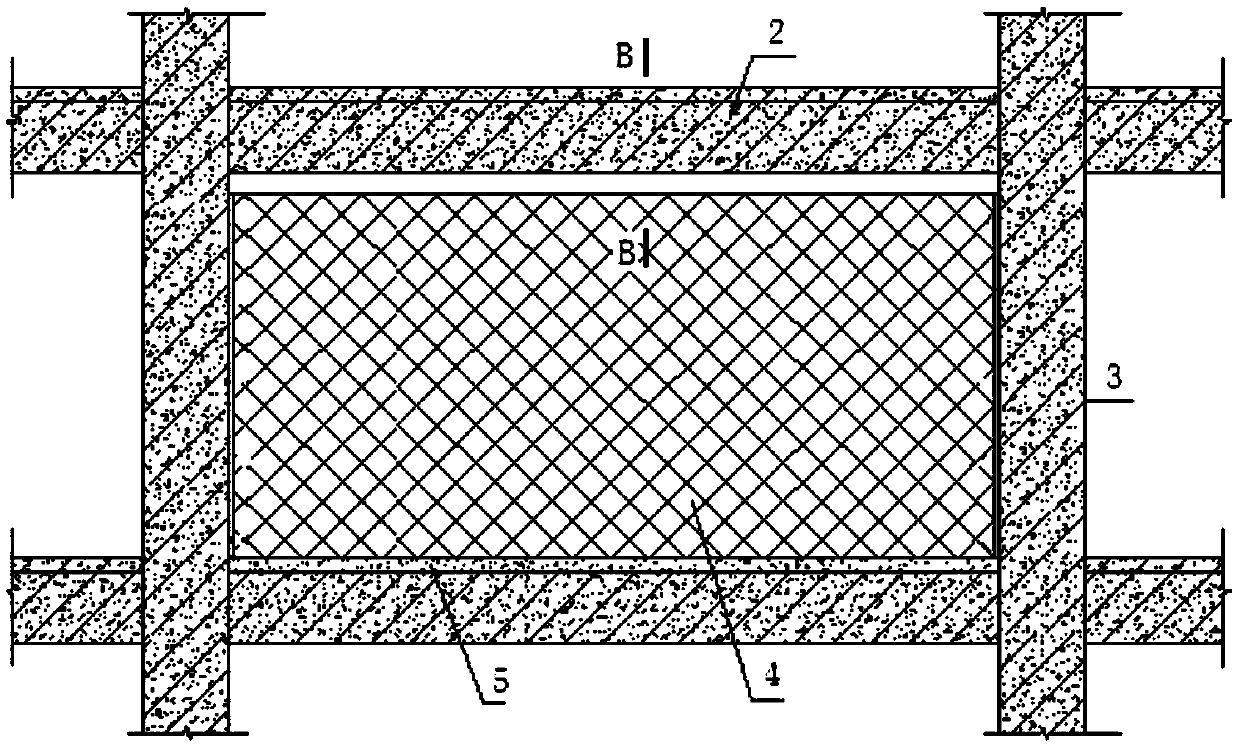

[0044] In a typical implementation of the present application, such as figure 1 As shown, on the basis of summarizing the application status of domestic prefabricated wall panels, the present invention proposes a prefabricated large slab filled wall concrete structure system and construction method:

[0045] 1. First, carry out the installation and construction of the prefabricated large slab filling wall 1;

[0046] 2. Temporarily fix and support the prefabricated large slab infill wall 1 after it is in place, and reserve a gap of 50-200mm between the top surface of the infill wall and the bottom surface of the cast-in-place concrete main structure 2 components according to the formwork requirements used in the project;

[0047] 3. Bind the steel bars of the main structure, and support the formwork and formwork support 10 of the main structure shear walls, columns, beams, floors and other components, and carry out the pouring construction of the concrete main structure 2;

...

Embodiment 2

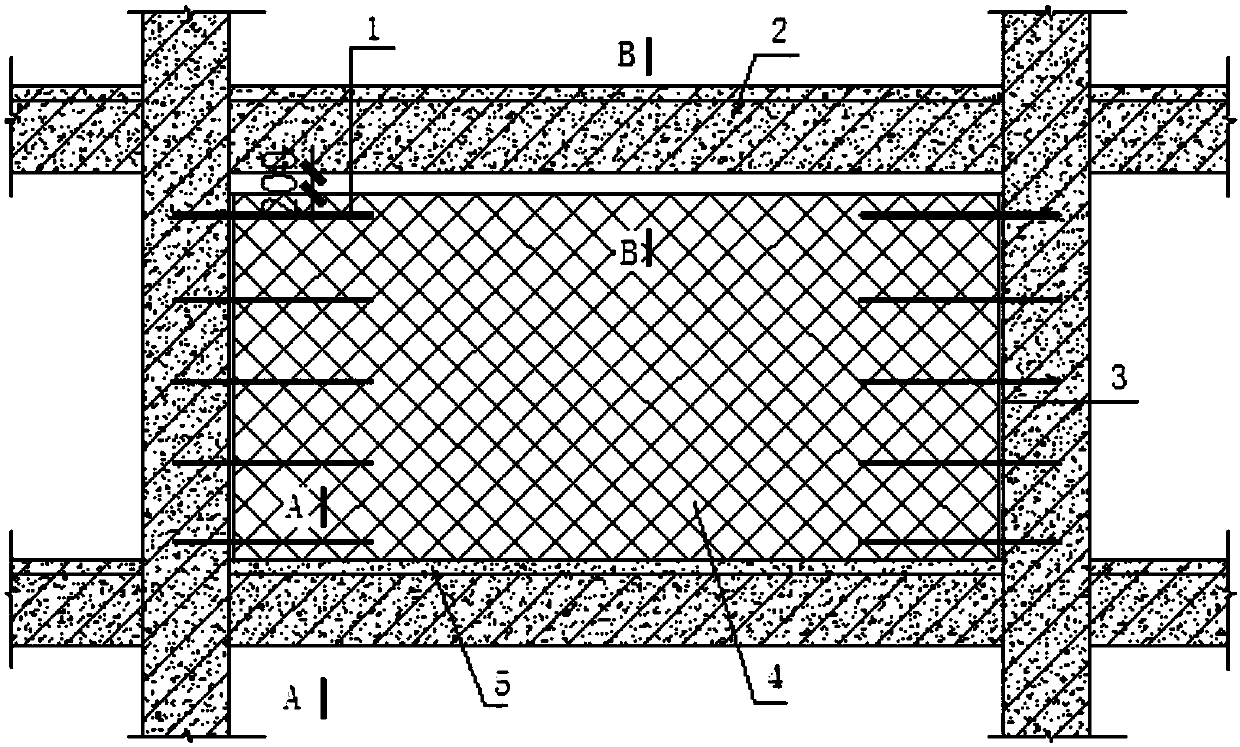

[0053] The difference between this embodiment and embodiment 1 is that the connection between the side of the prefabricated filled large wall panel and the main structure of cast-in-place concrete is different, and the rest of the methods are exactly the same as the embodiment, specifically as figure 2 , Figure 4 and Figure 5 shown;

[0054] Reasonable and reliable connection between the prefabricated large slab wall and the main structure is the key to the successful application of the prefabricated and filled large wall slab concrete structure construction technology; The connection also proposes another connection method. This connection must not only ensure the effective connection between the wall and the main structure, and the wall will not collapse under the action of the earthquake, but also ensure that the concrete structure bears all the loads, and the wall does not participate in bearing the vertical load. loads and horizontal loads; for specific connection me...

Embodiment 3

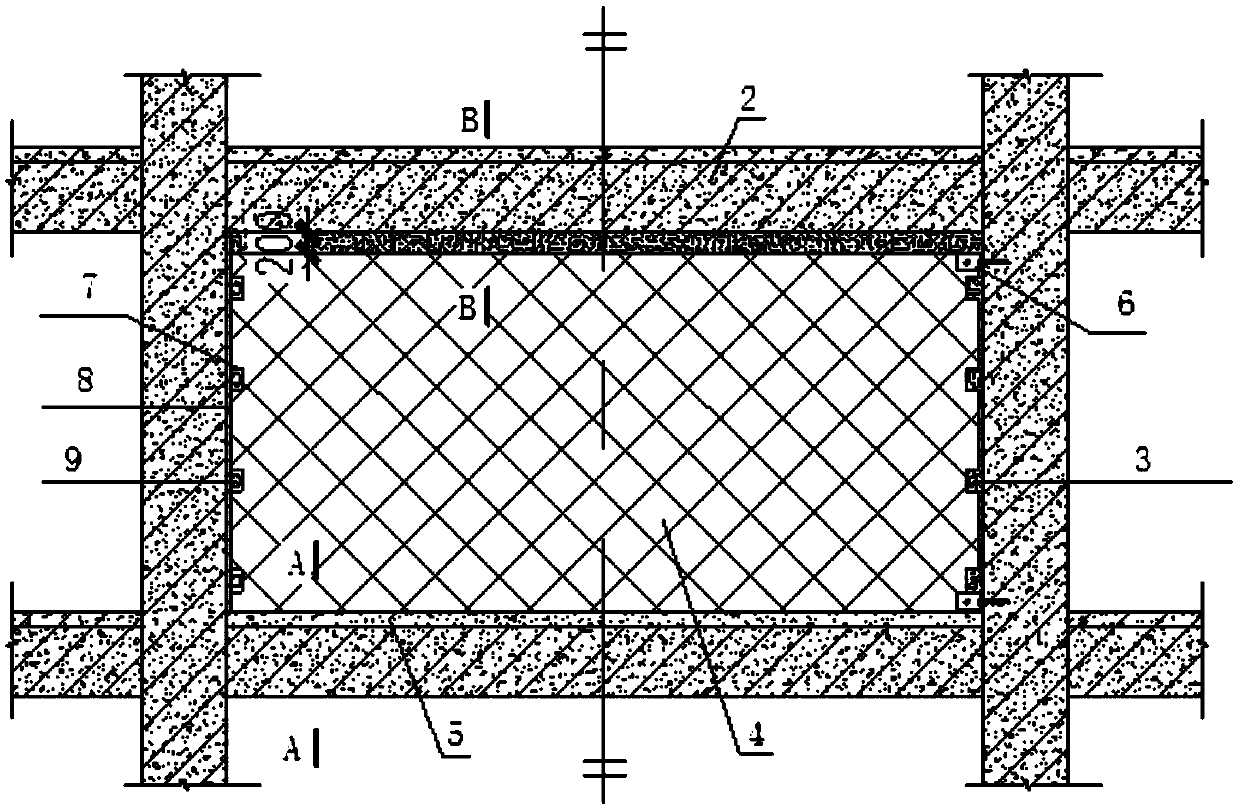

[0058] The difference between this embodiment and embodiment 1 lies in the connection between the side of the prefabricated filled large wall panel and the main structure of cast-in-place concrete, and the rest of the methods are completely the same as embodiment 1.

[0059] Reasonable and reliable connection between the prefabricated large slab wall and the main structure is the key to the successful application of the prefabricated and filled large wall slab concrete structure construction technology; The connection also proposes another connection method. This connection must not only ensure the effective connection between the wall and the main structure, and the wall will not collapse under the action of the earthquake, but also ensure that the concrete structure bears all the loads, and the wall does not participate in bearing the vertical load. loads and horizontal loads; for specific connection methods, see image 3 , Figure 4 and Figure 5 ;

[0060] Such as ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com