Vertical mixed connection structure and method of prefabricated internal wallboards for assembling shear wall structure

A hybrid connection and interior wall panel technology, applied in the direction of walls, building components, building structures, etc., to reduce the impact of connection performance, good fluidity, easy installation and temporary anchoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

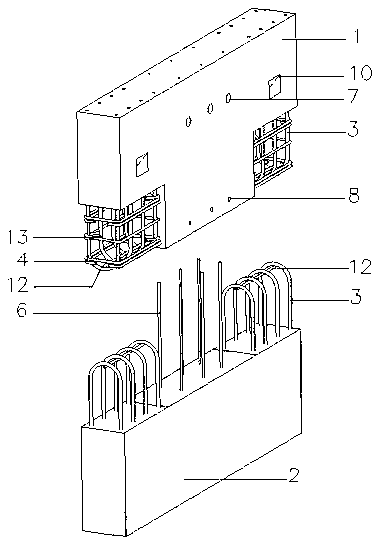

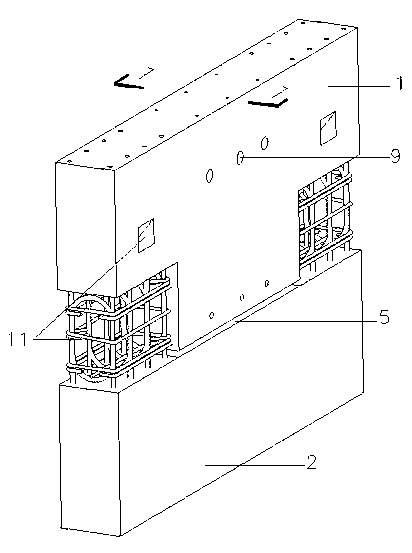

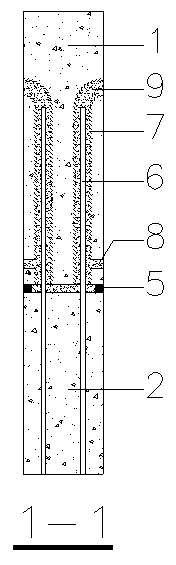

[0017] The vertical mixed connection structure of the prefabricated inner wall panels for assembling the shear wall structure of the present invention comprises prefabricated inner wall panels on the upper layer of the shear wall, prefabricated inner wall panels on the lower layer of the shear wall, vertical U-shaped closed steel bars, horizontally distributed steel bars, and joints Sitting grout layer, vertical grout anchor reinforcement, metal corrugated grout anchor pipe, grouting material, grout opening, reserved pouring hole, cast-in-place concrete, horizontal reinforcing steel bar, stirrup; prefabricated inner wall of upper layer of prefabricated shear wall by floor There are no concrete vertical U-shaped closed steel bars at the exposed parts of the left and right lower corners of the edge members on both sides of the slab, and the vertical U-shaped closed steel bars above the exposed members of the edge members on both sides of the lower prefabricated inner wall panels a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com