Construction method for erecting electric transmission line double-leg angle steel tower by helicopter unit

A technology for power transmission lines and helicopter units, which is applied to towers, building types, buildings, etc., and can solve problems such as the difference in the root opening size of the hoisting tower section and the tower section in place, difficulty in positioning, and inability to position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

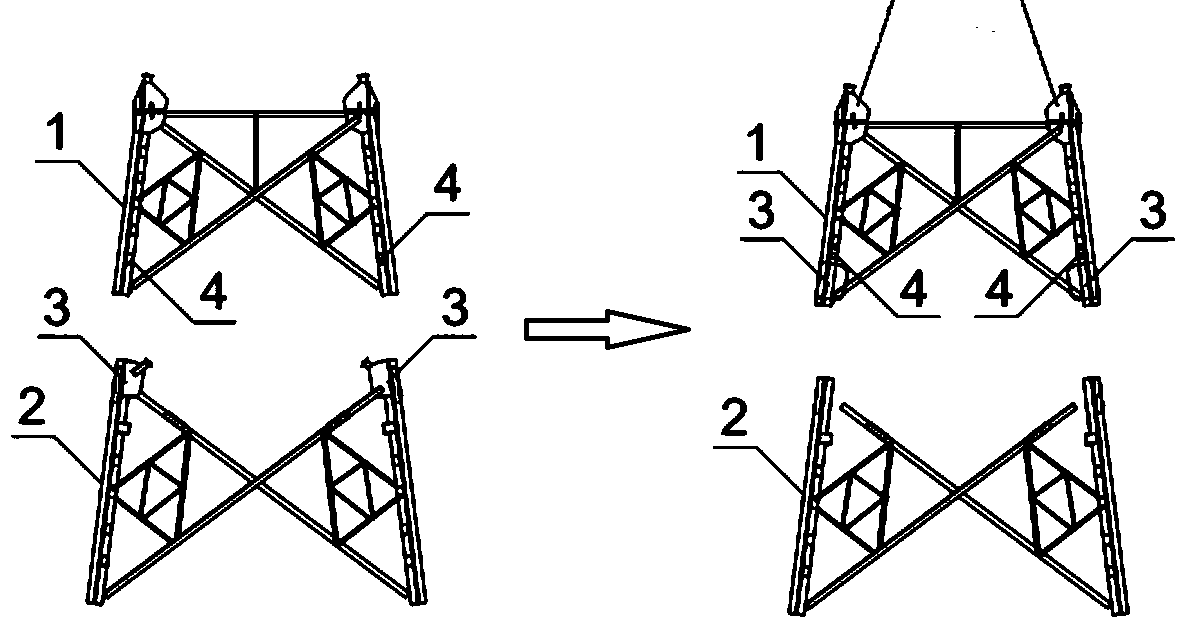

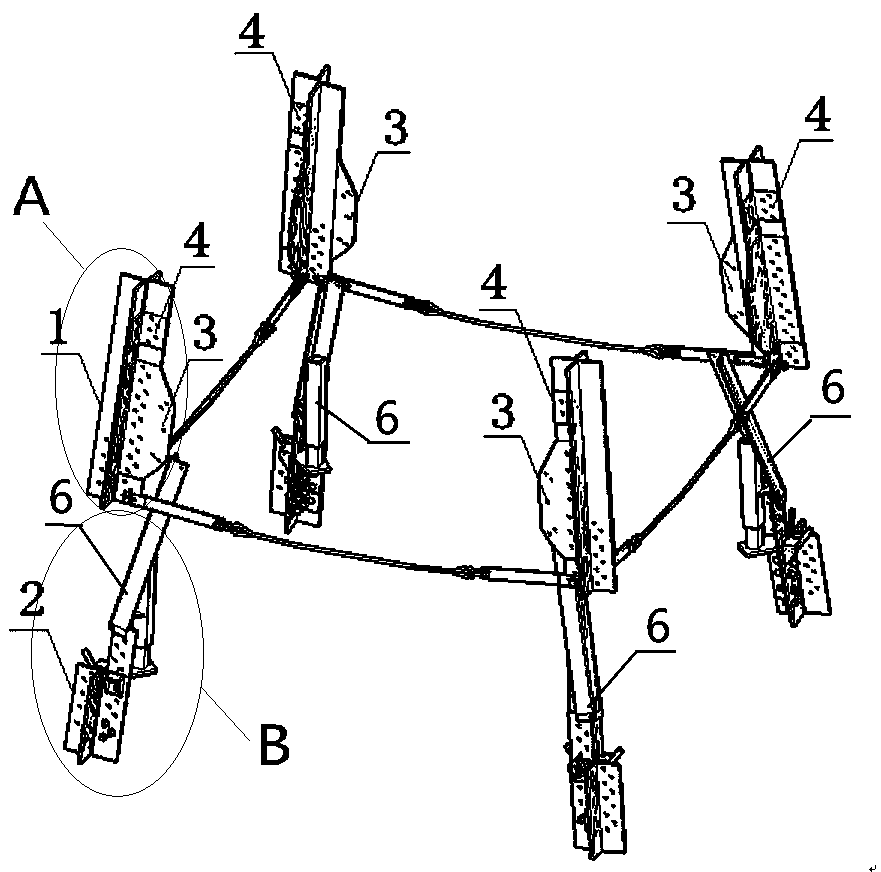

[0021] Such as Figure 1-4 As shown, the construction method of the two-leg angle steel tower of the transmission line erected by helicopter comprises the following steps:

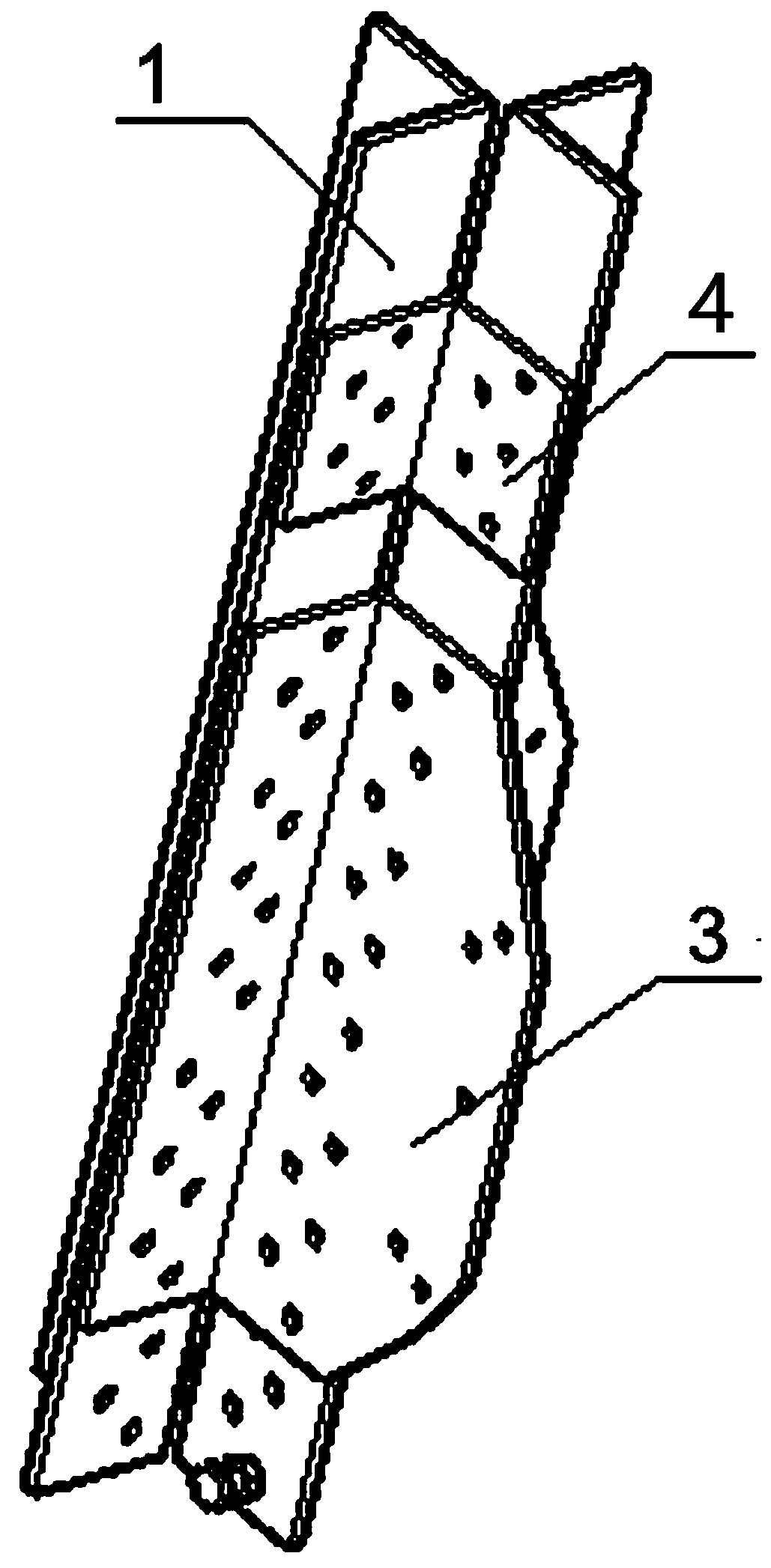

[0022] 1) Perform pretreatment on the hoisting tower section 1, move the inter-section cross plate 3 above the breaking point of the main material 5 of the limbs, that is, install it on the hoisting tower section 1, and the installation of the docking auxiliary kit 6 cannot be affected after the upward movement , and then fixed by 2-3 bolts. At the same time, in order to facilitate manual auxiliary installation, the inter-section cross plate 3 is fixed to the bolt hole of the oblique material of the upper tower section with brown ropes, and the brown ropes always bear a certain load. In addition, the main The material cross connecting plate 4 is moved up synchro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com