Workpiece clamping device for engraving machine

A clamping device and engraving machine technology, which is applied in the field of engraving machines, can solve the problems of inability to process and difficult to process, and achieve the effect of simple structure and good clamping and fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

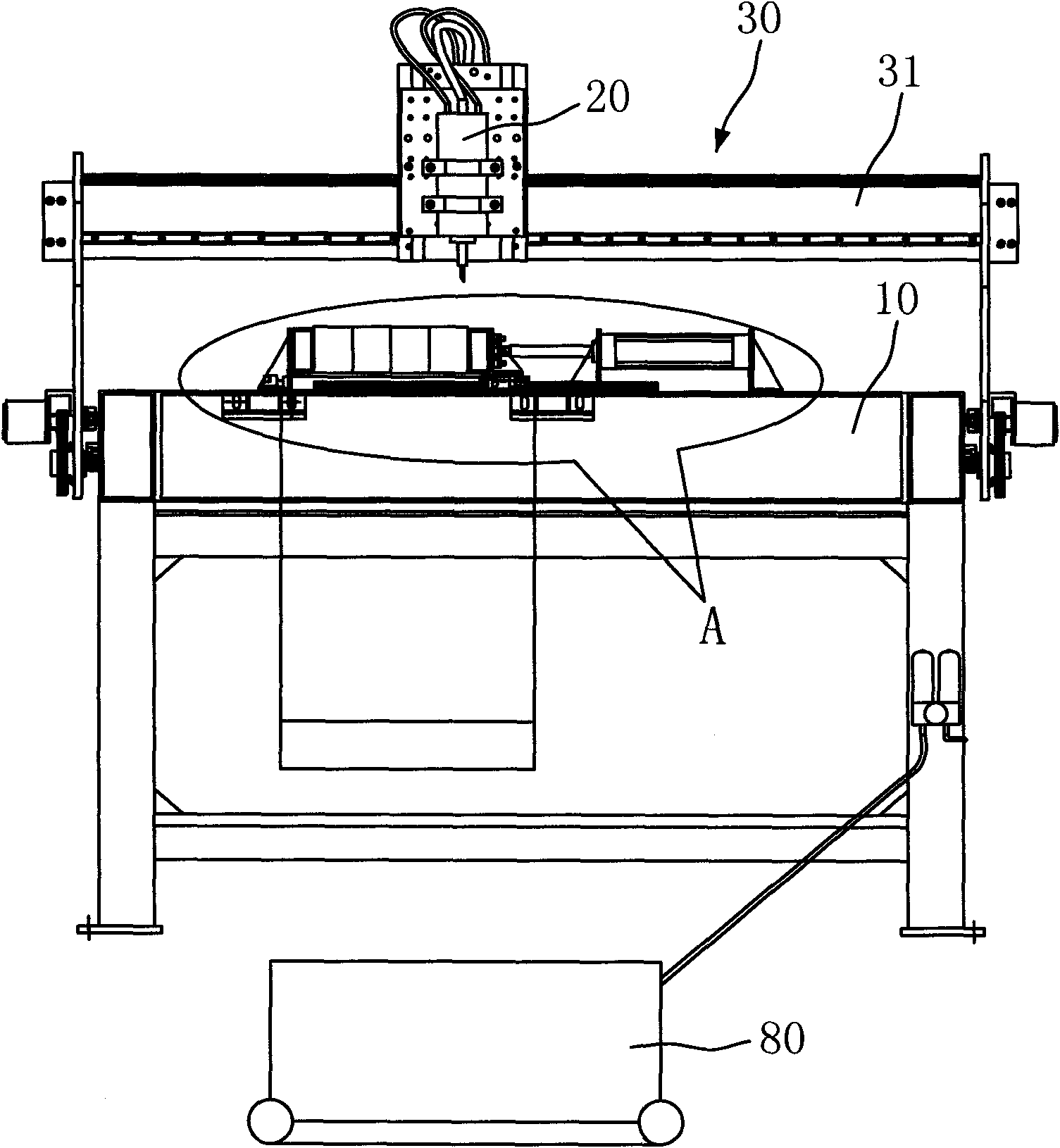

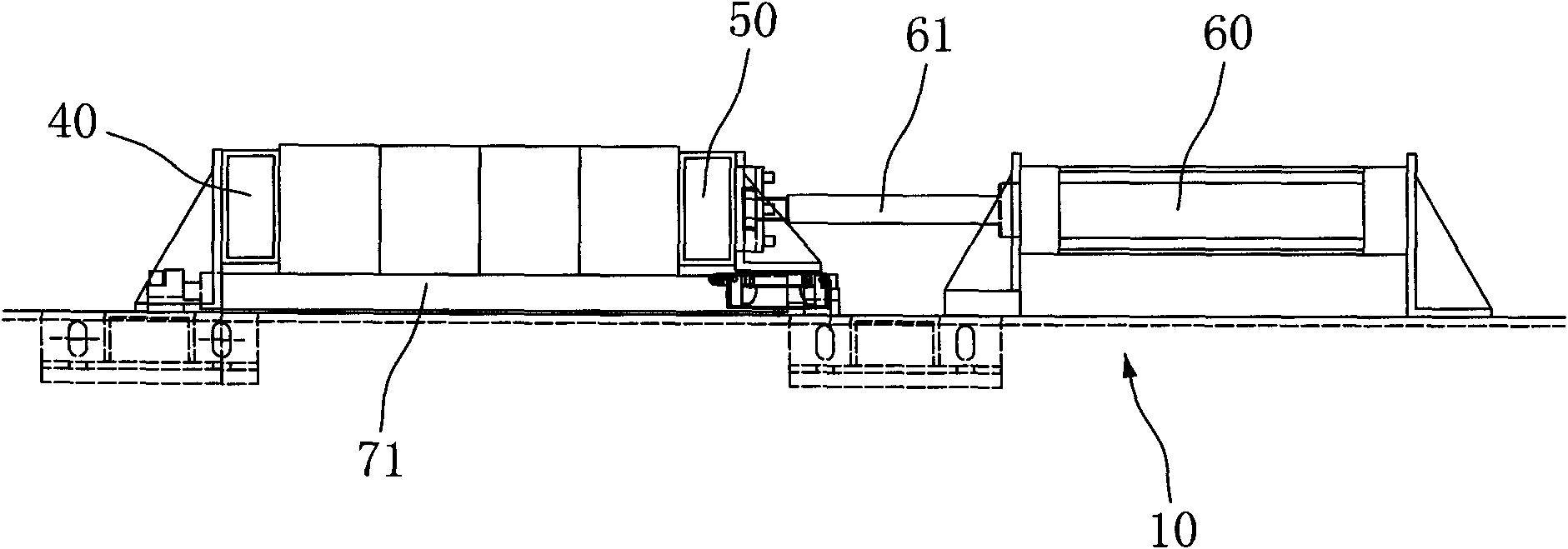

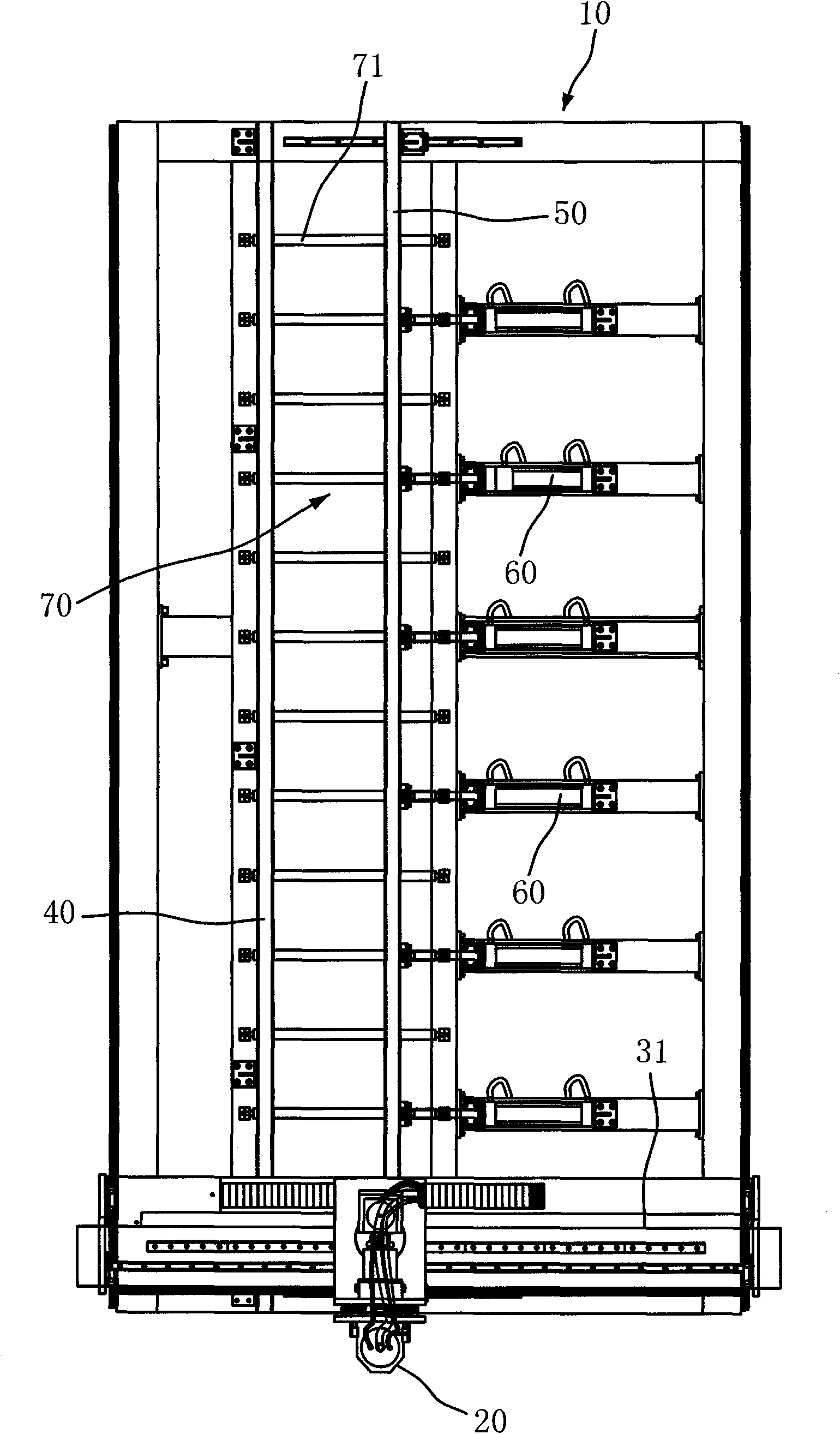

[0009] Such as Figure 1-3 As shown, a workpiece clamping device of an engraving machine includes a working table 10 and a processing head 20 erected on the upper side of the working table 10. A first clamping plate 40 and a second clamping plate 50 are provided on both sides of the workpiece to fix the workpiece in place. , The splint is arranged on the workbench 10, and the distance between the splints is adjustable.

[0010] The invention adopts the clamping method of clamping plates. The two clamping plates are in line or surface contact with the workpiece, so the clamping force is greatly increased, thereby ensuring that the position of the workpiece will not change during engraving. Improve the engraving quality and speed.

[0011] Such as image 3 As shown, the first clamping plate 40 and the second clamping plate 50 are both arranged along the length direction of the worktable 10 to facilitate the processing of strip-shaped profiles.

[0012] The first splint 40 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com