Wineglass-shaped section steel-concrete composite beam and construction method thereof

A construction method and concrete technology, applied in the direction of load-bearing elongated structural components, structural elements, building components, etc., can solve problems such as poor torsion resistance, slippage at the interface between steel and concrete, poor lateral stability, etc., to achieve Good comprehensive economic performance, reasonable mechanical performance, and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

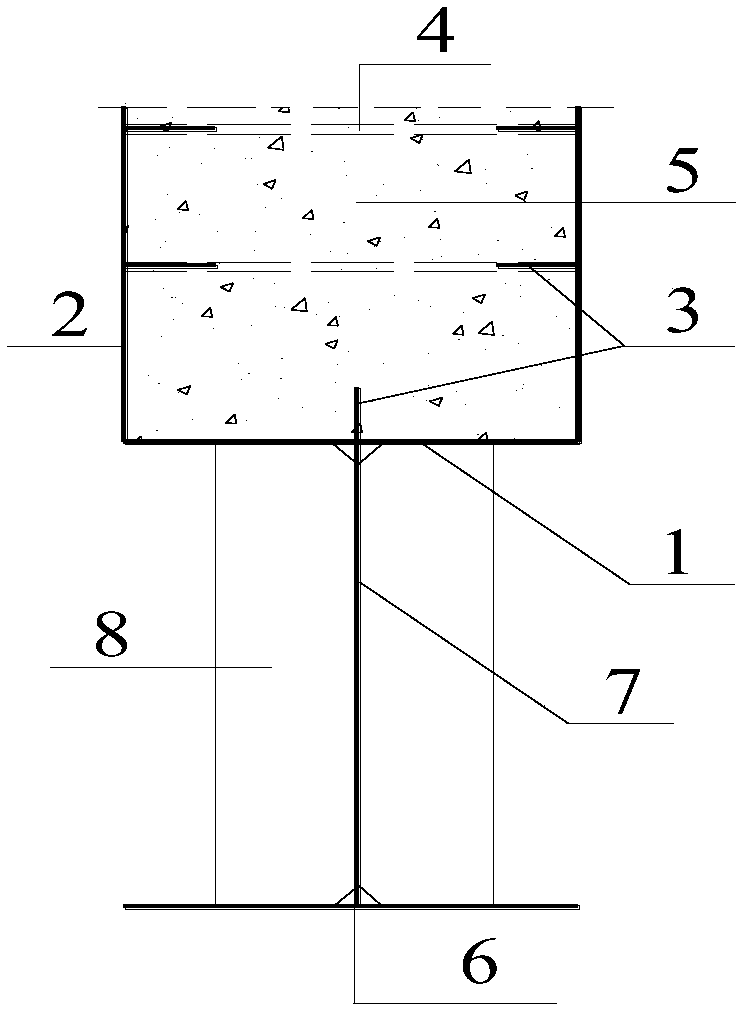

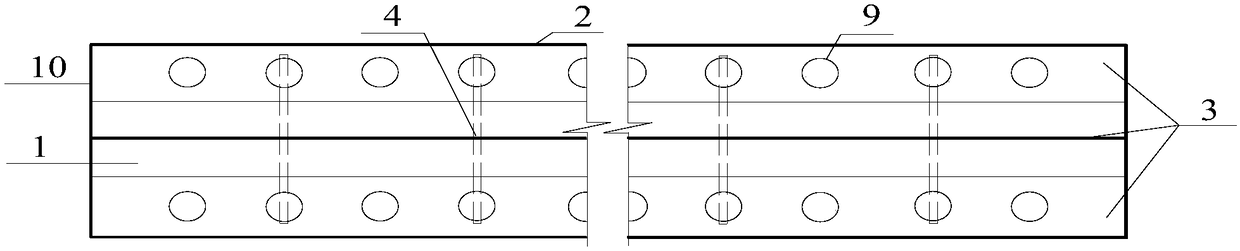

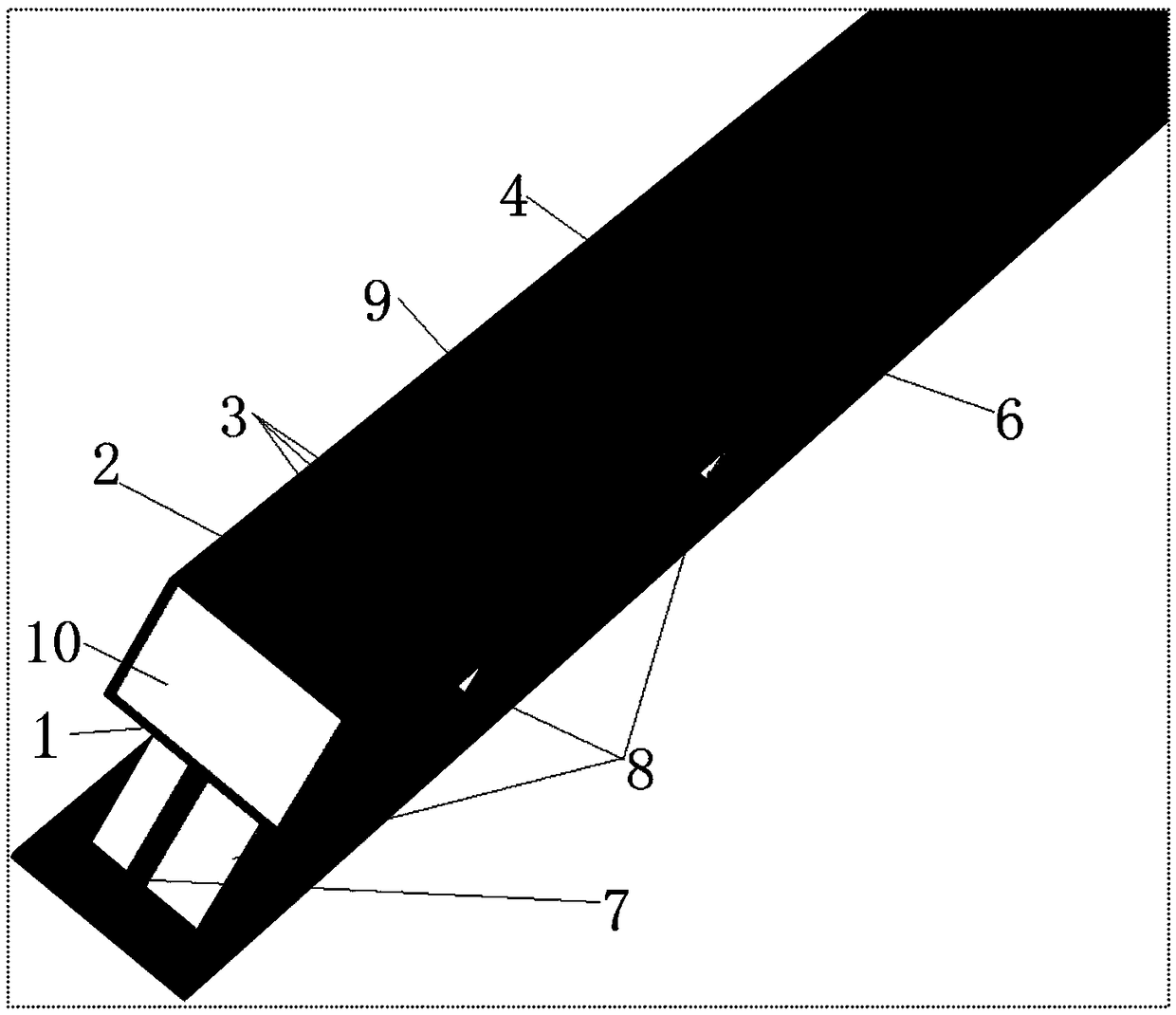

[0030] as attached figure 1 , 2 As shown in , 3, a steel-concrete composite beam with a wineglass-shaped cross-section includes an I-shaped cross-section steel beam, and two upper webs 2 and two end plates 10 in the vertical direction are respectively welded to the edges around the upper flange 1, so that An open steel box is formed on the upper flange 1, and a PBL stiffener 3 is respectively arranged on the inner surface of the two upper webs 2 and the upper surface of the upper flange 1 along the longitudinal direction, and then several tie rods 4 are used to connect the two upper webs 2 3 pairs of PBL stiffeners are pulled up at a certain distance, and the open steel box is filled with concrete.

[0031] As another embodiment of the present invention, according to the different aspect ratios of the upper web, two or more PBL stiffeners 3 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com