Self-supporting deformed steel-encased concrete composite beam

A technology of concrete and outer steel, applied in building components, floors, buildings, etc., can solve problems such as scaffolding, multi-manpower, construction period, auxiliary materials, material waste, etc., so as to avoid concrete cracking, The effect of reducing the amount of concrete and a clean and tidy visual space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

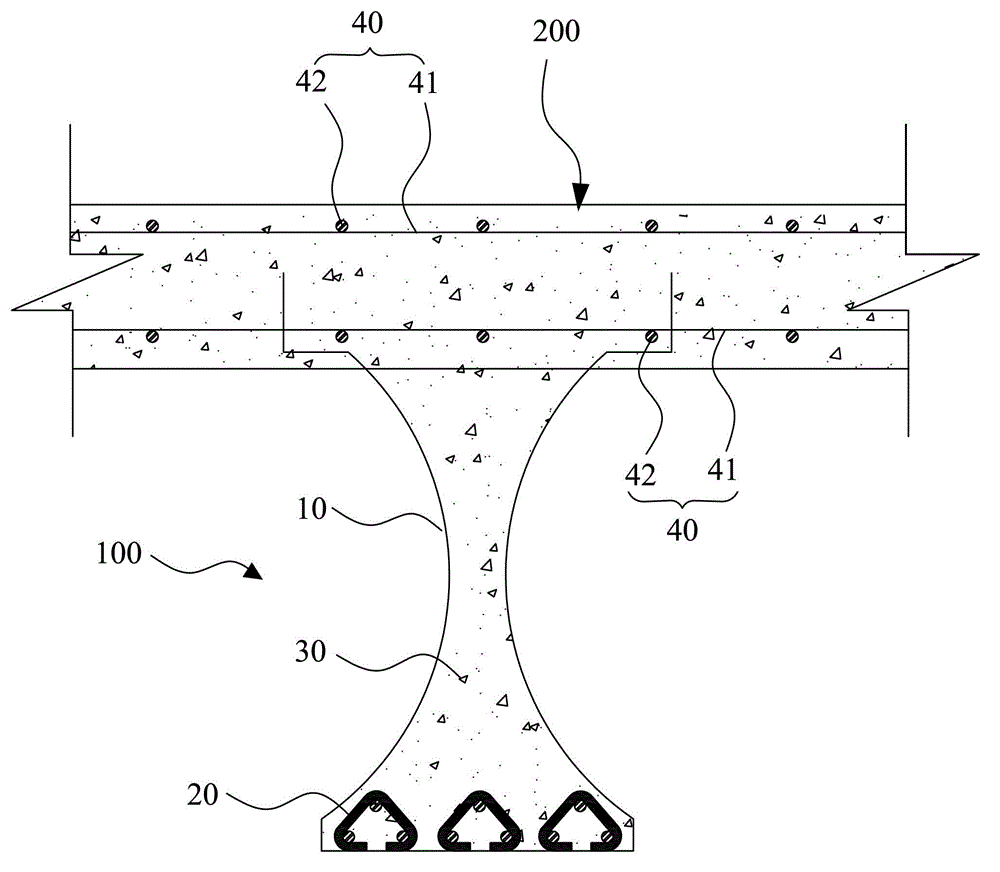

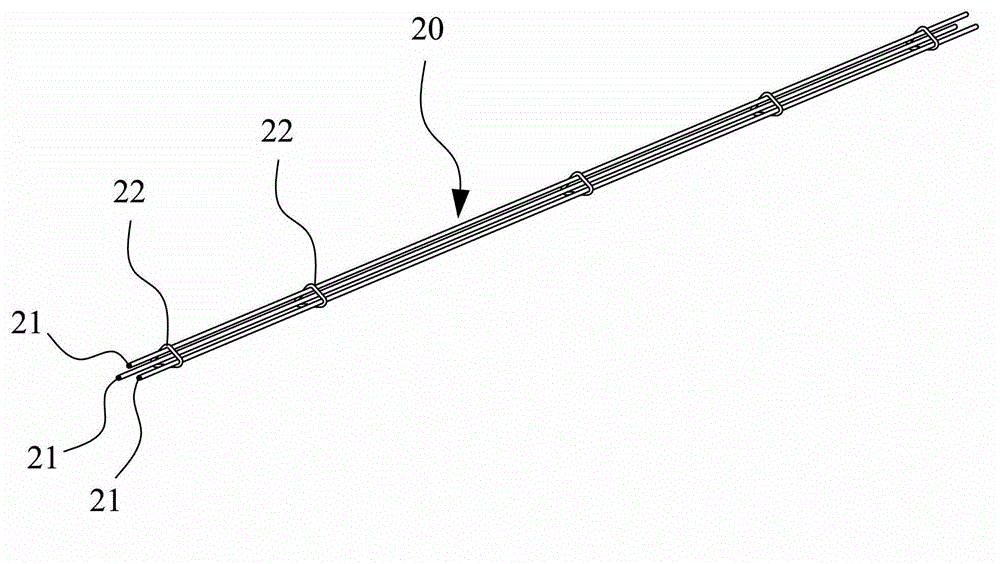

[0033] Please refer to figure 1 As shown, it shows the specific structure of the preferred embodiment of the present invention, the self-supporting special-shaped outer cladding steel-concrete composite beam 100 includes special-shaped thin-walled steel 10, long steel skeleton 20 and concrete filler 30, the The long and long bar frame 20 is arranged in the special-shaped thin-walled steel 10, and the concrete filler 30 is integrally poured from the special-shaped thin-walled steel 10, the long steel bar frame 20 and the floor cover 200, so that the self-supporting special-shaped outsourcing steel-concrete composite beam 100 and the floor cover 200 are connected together to form a common force bearing body.

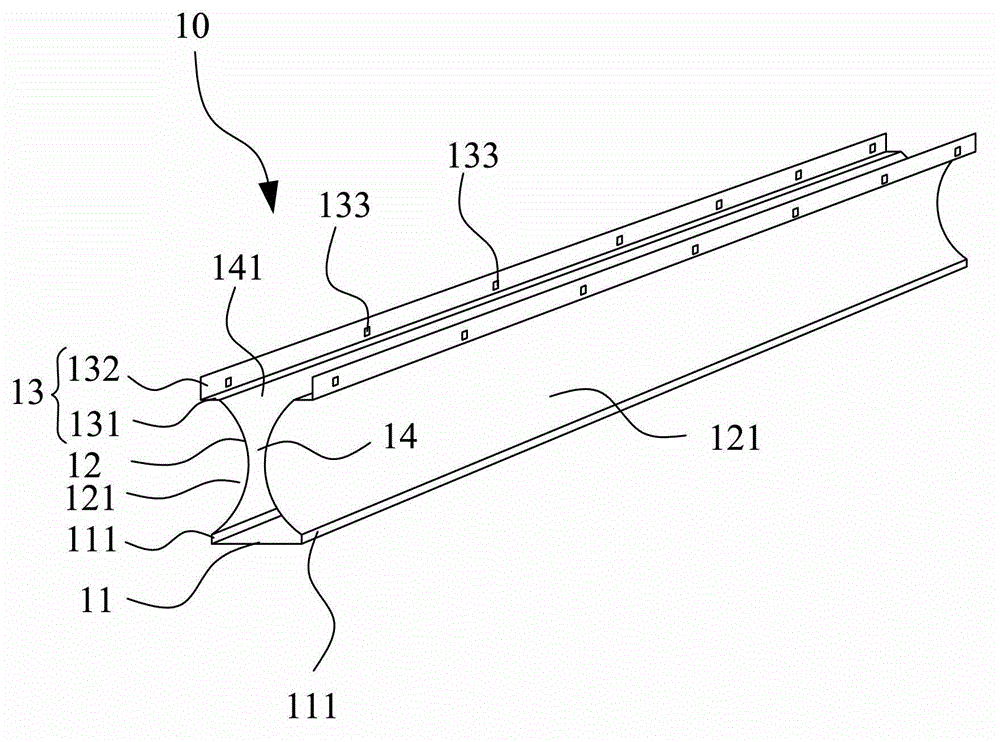

[0034] Among them, such as figure 2 As shown, the special-shaped thin-walled section steel 10 is formed by cold-bending ordinary steel plate, high-strength steel plate or other structural steel plates, and includes a lower bottom plate 11, two webs 12 and an upper flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com