Tire mold side panels for quick change of blocks

A technology of tire molds and movable type blocks, which is applied to tires, household appliances, and other household appliances, etc., can solve the problems of long time period, large manpower, and material resources of movable type blocks, and improve production efficiency, improve work efficiency, and save demolition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

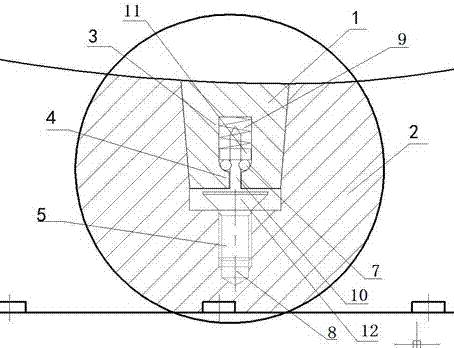

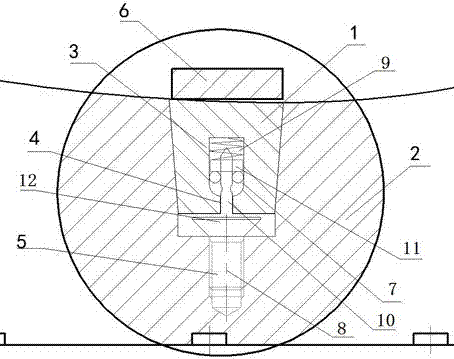

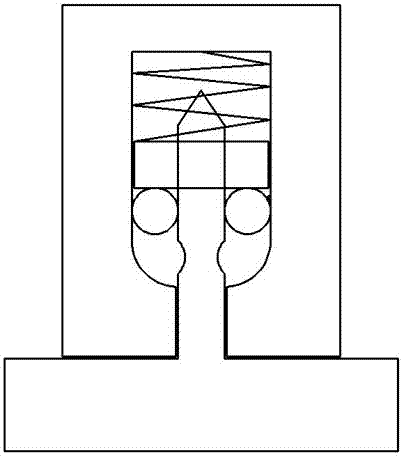

[0030] In order to overcome the complement of the existing technical solutions, the technical solution provided by the present invention is: change the connection mode between the movable type block and the side plate and the material of the movable type block, so that it is no longer necessary to carry out cumbersome bolt disassembly and assembly when the movable type block is disassembled. The specific method is in The fastening device matching part is installed in the groove of the side plate of the mold, and the fastening device is embedded on the bottom of the movable type block. The fastening device uses the spring force as the driving force to fasten the columnar body of the fastening device matching part in the fastening device. When disassembling, a strong magnetic field is applied to the top of the movable type block. Since the movable type block is made of non-magnetic material, the magnetic field will press the spring upwards, so that the fixing pin is separated from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com