A prefabricated assembly shear wall horizontal grout anchor connection structure

A technology of prefabricated assembly and connection structure, applied in the direction of walls, building components, building structures, etc., can solve the problems of limited ability to transmit external forces in the horizontal direction, high cost, large amount of steel bars, etc., to reduce on-site formwork, improve External force capability, the effect of simplifying installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with embodiment.

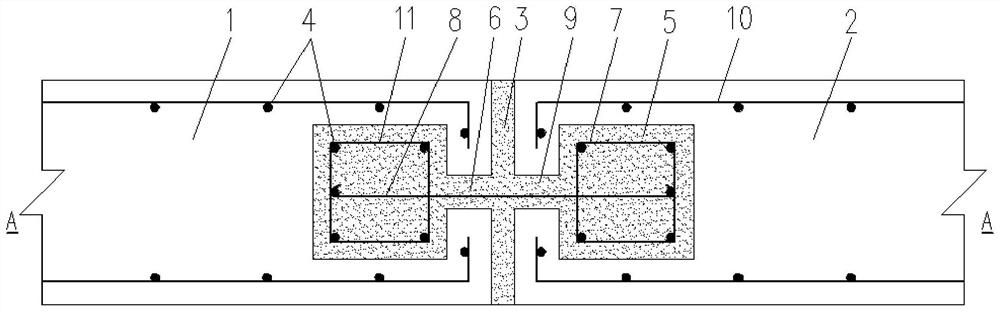

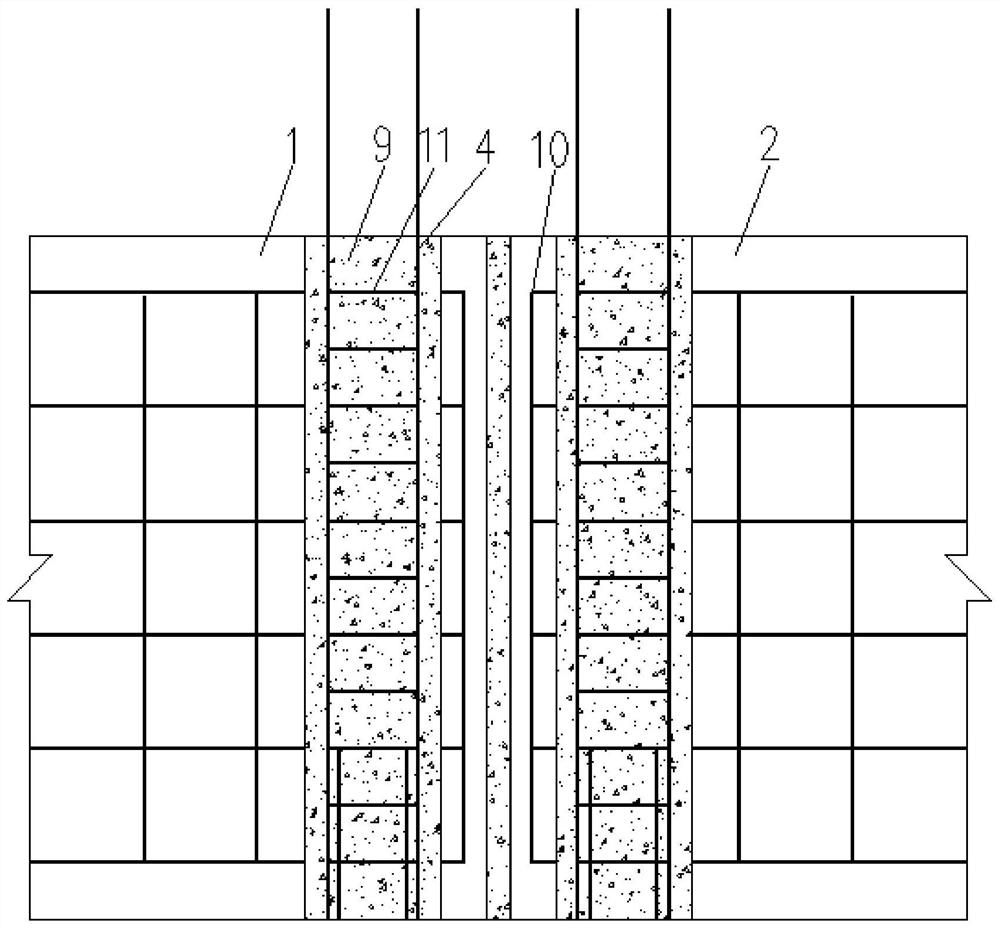

[0020] according to Figure 1 ~ Figure 2 As shown, a prefabricated assembly type shear wall horizontal grout anchor connection structure includes: a first shear wall 1 and a second shear wall 2 arranged side by side in a horizontal direction, with a gap 3 between them, and the gap 3 The width is 20-40mm, the first shear wall 1 and the second shear wall 2 are pre-embedded with longitudinal reinforcement 4 along the longitudinal direction, and the first shear wall 1 and the second shear wall 2 are respectively provided with The first through hole 5 and the second through hole 6, the first through hole 5 is arranged longitudinally, the second through hole 6 is arranged transversely, and its two ends are connected with the first through hole 5 and the first through hole 5 and the second through hole 6 respectively. The gap 4 is connected, and the width of the second through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com