Self-adhesive type water stop and production method

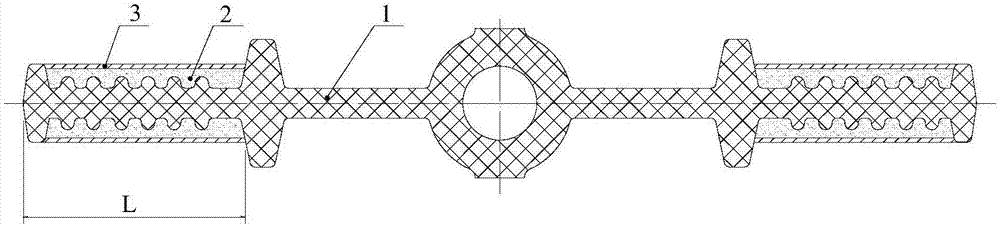

A production method and waterstop technology, which are applied in the types of adhesives, adhesives, water conservancy projects, etc., can solve the problems of poor joint handling, inconvenient installation, water leakage, etc., to achieve reliable lap quality and reduce contact area. ,Easy to install in place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The raw materials for the preparation of the hot-melt pressure-sensitive adhesive consist of 100 parts by weight of polyisobutylene, 70-100 parts of styrene-isoprene-styrene, 110 parts of C5 petroleum resin, 3.0 parts of titanium dioxide or carbon 3.0 parts of black, 1.0 part of antioxidant, 0.5 part of light stabilizer, and 0.5 part of ultraviolet absorber.

[0028] The hot-melt pressure-sensitive adhesive is prepared as follows: the raw materials for the hot-melt pressure-sensitive adhesive are added to the kneader in batches, heated, melted and stirred evenly, and the stirring speed is controlled at 100-150 rpm; After each component is completely melted, continue to stir for 1.5-2 hours, and keep the temperature at 160-180°C; finally discharge the material for use.

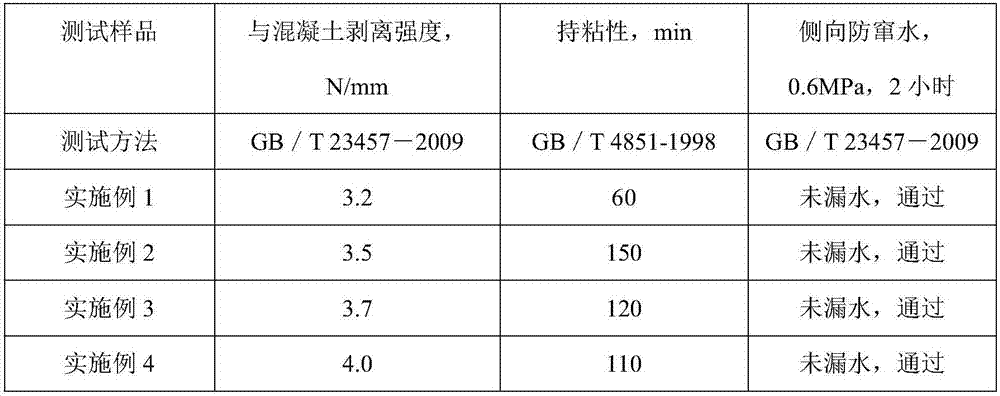

Embodiment 1

[0030] The raw materials for the preparation of the hot-melt pressure-sensitive adhesive are composed by parts by weight: polyisobutylene 100, styrene-isoprene-styrene 70, C5 petroleum resin 110, titanium dioxide 3.0, antioxidant 1.0, light stabilizer 0.5 , UV absorber 0.5.

[0031] Add the prepared raw materials into the kneader in batches, heat them to melt and stir them evenly, and the stirring speed is controlled at 100-150 rpm; after each component is completely melted, continue stirring for 1.5-2 hours, and keep the temperature At 160 ~ 180 ° C; the final material is ready for use.

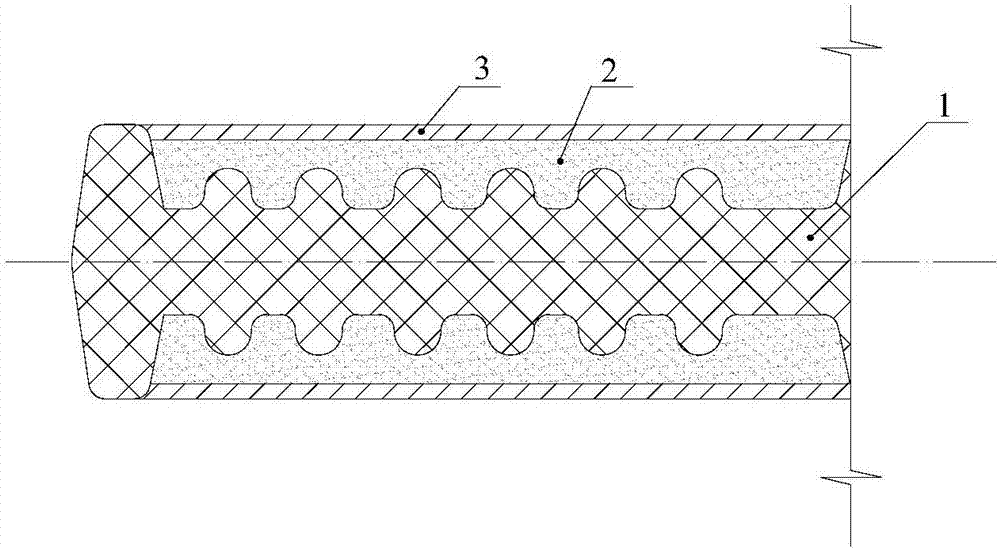

[0032] Preheat the waterstop substrate 1 in a drying oven at 80-100°C for 5-10 minutes, then heat the hot-melt pressure-sensitive adhesive to 160-180°C, and coat it on the waterstop after it is completely melted A waterproof adhesive layer 2 is formed on the upper surface and the lower surface of the water-stop section L of the substrate 1 with a thickness of 1.0 mm. After the surface temp...

Embodiment 2

[0035] The raw materials for the preparation of hot-melt pressure-sensitive adhesives are composed by weight parts: polyisobutylene 100, styrene-isoprene-styrene 80, C5 petroleum resin 110, carbon black 3.0, antioxidant 1.0, light stabilizer 0.5 , UV absorber 0.5.

[0036] Add the prepared raw materials into the kneader in batches, heat them to melt and stir them evenly, and the stirring speed is controlled at 100-150 rpm; after each component is completely melted, continue stirring for 1.5-2 hours, and keep the temperature At 160 ~ 180 ° C; the final material is ready for use.

[0037] Preheat the waterstop substrate 1 in a drying oven at 80-100°C for 5-10 minutes, then heat the hot-melt pressure-sensitive adhesive to 160-180°C, and coat it on the waterstop after it is completely melted A waterproof adhesive layer 2 is formed on the upper surface and the lower surface of the water-stop section L of the substrate 1 with a thickness of 1.0 mm. After the surface temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com