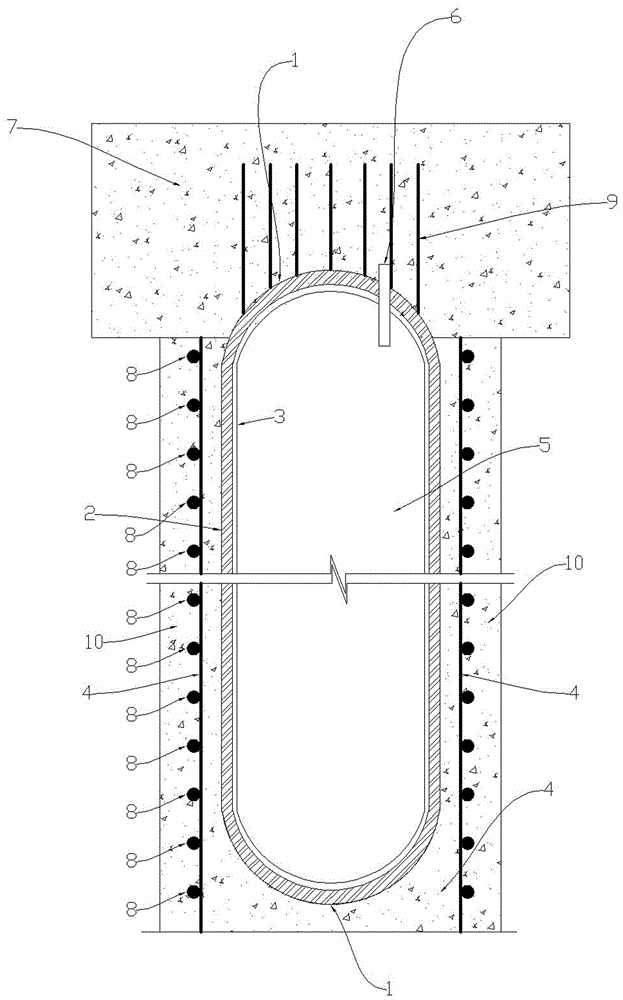

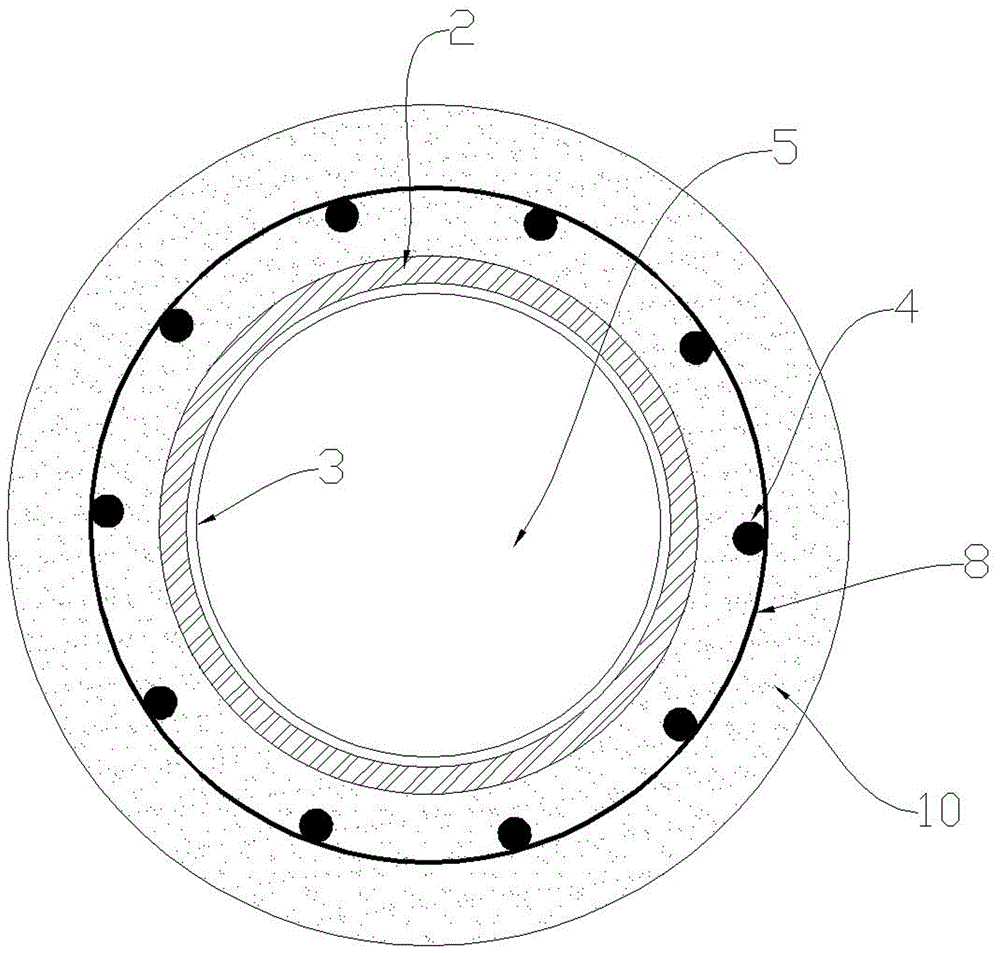

Composite pile combining reinforced concrete bored pile with pneumatic prestressed steel pipe pile

A technology of reinforced concrete and steel pipe piles, which is applied in sheet pile walls, foundation structure engineering, construction, etc., and can solve the problems of steel pipes not being able to exert tensile strength, large consumption of concrete, and high consumption of steel materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Summary of the Invention The specific implementation of the present invention has been described in detail, and will not be repeated here. It needs to be explained: 1. The main function of the anchoring steel bar 9 is to firmly tie the steel pipe pile and the pile cap 7; 2. The main function of the inflatable membrane 3 The function is to protect the high-pressure gas from leakage, so that the pressure of the high-pressure gas remains constant; 3. In order to facilitate the transportation and installation of steel pipe piles, the cylinder body 2 can be transported and welded in sections. After the cylinder body 2 is installed , then install the inflatable film 3, and finally weld the uploading force cover 1 and the cylinder body 2; four, the present invention is actually a composite pile that combines the reinforced concrete pile and the inflatable prestressed steel pipe pile together to be stressed together, if After the construction of the building is completed, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com