Ceramic base lightweight bulletproof helmet and the production method

A bulletproof helmet and a manufacturing method technology are applied in the field of ceramic-based lightweight bulletproof helmets and their manufacturing, which can solve the problems of heavy weight and the protection level of bulletproof helmets made of polymer materials that are easy to be found, and achieve light weight, good thermal insulation performance, and guaranteed The effect of protective properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

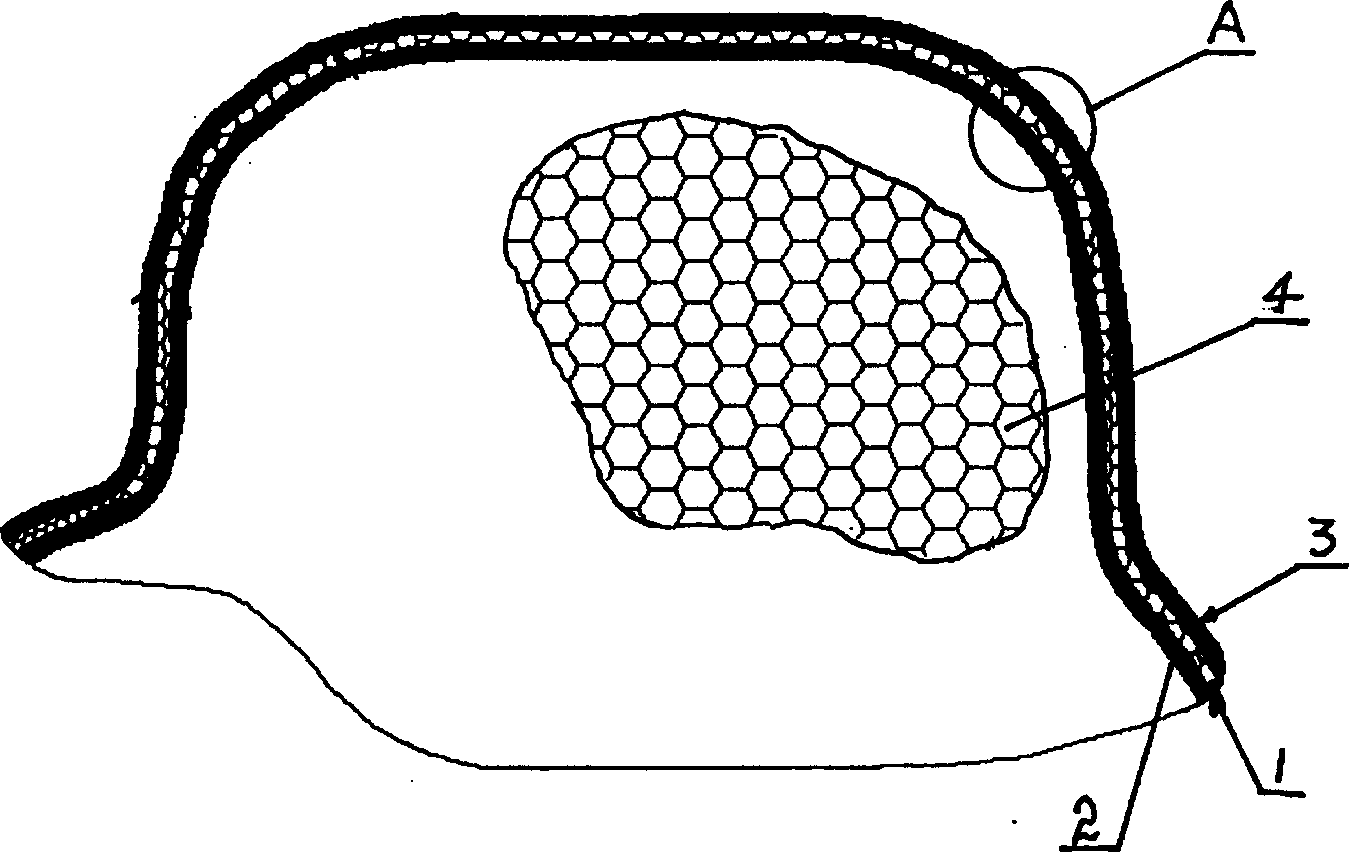

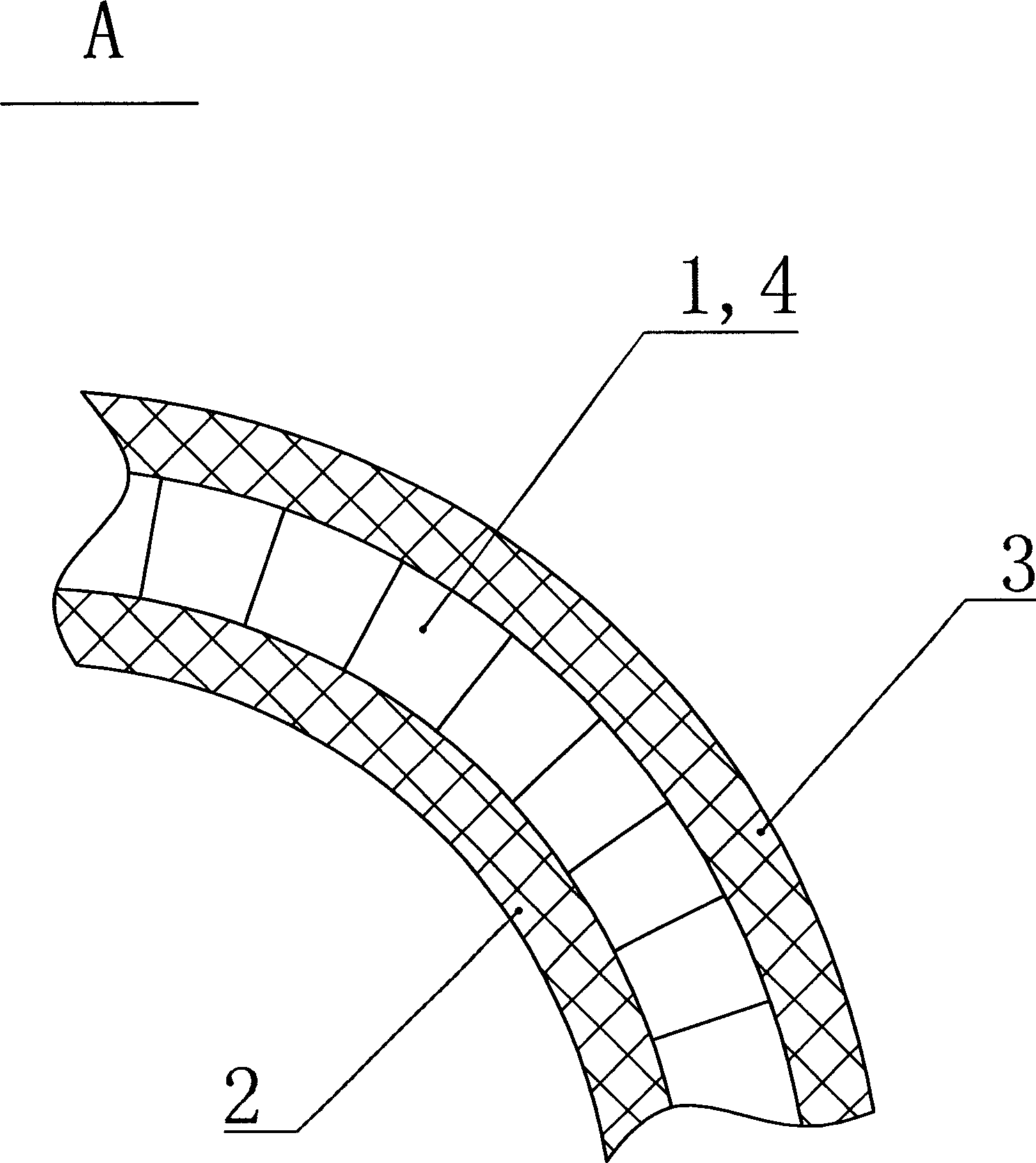

[0012] see figure 1 and figure 2 , The helmet of the present invention is composed of a ceramic matrix layer 1 in the middle, a PE layer 2 attached to the inner side of the ceramic matrix layer 1, and a PE layer 3 attached to the outer side of the ceramic matrix layer 1 and formed by thermocompression bonding.

[0013] The ceramic matrix layer 1 is composed of a plurality of polygonal prisms, pyramids and truncated polygons 4 , and the facets between adjacent ones of them are closely attached to each other without gaps. The number of edges of the polygonal prism, polygonal pyramid and polygonal truss 4 is 3-7. The different curvatures of different regions of the helmet are formed by splicing polygonal pyramids with different tapers and polygonal trusses and polygonal prisms. The material of the ceramic matrix layer 1 includes aluminum oxide, boron carbide, silicon carbide or silicon nitride.

[0014] Through testing, the present invention can effectively resist automatic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com