Fiber-reinforced metal/ceramic laminar composite material protective board

A fiber reinforced, composite material technology, applied in the direction of the structure of the armor plate, can solve the problems of fragility, poor impact resistance, low hardness, etc., to achieve good protection against high-speed projectile strikes, good tear resistance, and hardness. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] One mode of the active metal brazing process described in the present invention is: the active metal brazing material is evenly brushed on the metal layer to be combined, the fiber layer and the surface of the ceramic layer, and they are placed together, first in the oven Dry the organic solvent, then place it in a vacuum electric furnace, slowly raise the temperature to 600°C-1650°C, keep it warm for 10-15 minutes, and cool down with the furnace to obtain a well-bonded fiber-reinforced metal / ceramic layered composite material protection plate.

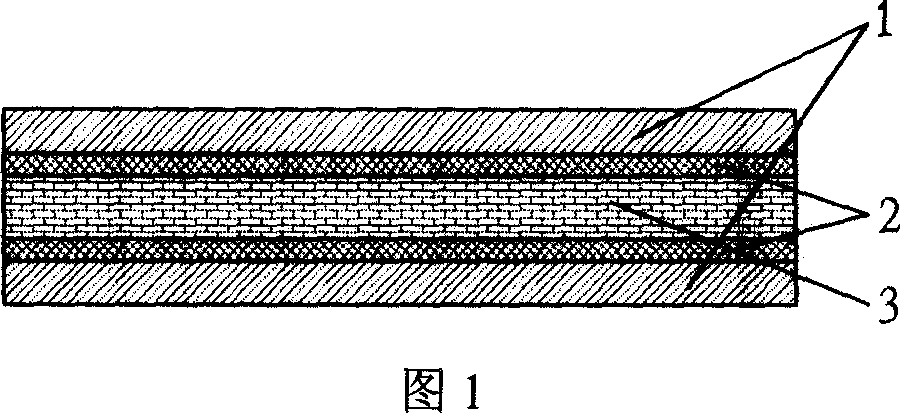

[0026] The fiber-reinforced metal / ceramic layered composite is shown in Figure 1:

[0027] In Figure 1, 1 is a metal material layer, 2 is a fiber layer, and 3 is a ceramic material layer. The 3 materials can be manufactured by active metal brazing process. The layered structure similar to a sandwich can be a single layer or a multilayer . The thickness of the metal layer is 0.5-10mm, the thickness of the ceramic layer is 1-20...

Embodiment 2

[0030] The active casting process described in the present invention refers to reducing the surface tension of the metal melt through the physical or chemical method at a high temperature of 600°C to 1650°C, so that it can be wetted and solidified on the ceramic surface, so that the fiber , metal and ceramic welded together.

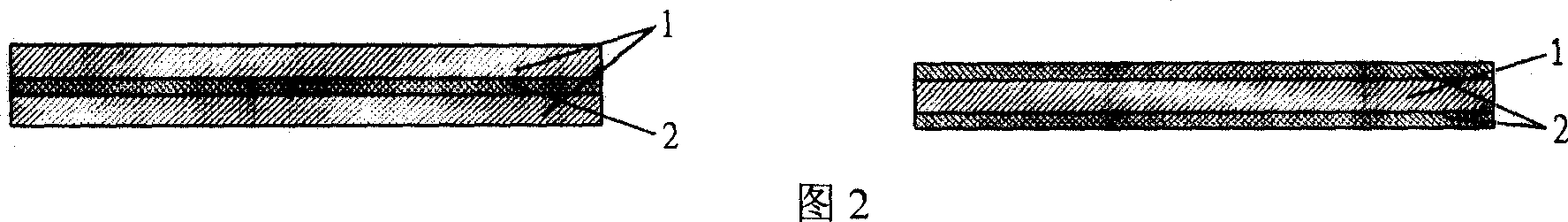

[0031] The resulting composite material is shown in Figure 2:

[0032] 1 in Fig. 2 is a metal material layer, and 2 is a fiber material layer, and a similar layered structure can be a single layer or a multilayer stack. The thickness of the metal layer is 0.5-10 mm, and the fiber layer can be a single layer or can be formed by stacking multiple layers of fibers. The metal layer is a complete plate, and the fiber layer can be a complete piece or welded by multiple pieces of fiber.

[0033] The composite structure of this embodiment can also be fabricated by active metal brazing method and powder sintering method.

Embodiment 3

[0035]One method of the powder sintering process of the present invention is: evenly brush the powder sintering material on the surface of the metal layer, fiber layer and ceramic layer to be combined, and put them together, first dry the organic solvent in an oven After drying, place it in a vacuum electric furnace, raise the temperature to 1200°C-1600°C, keep it warm for 45-120 minutes, and cool down with the furnace to obtain a well-bonded fiber-reinforced metal / ceramic layered composite protective plate.

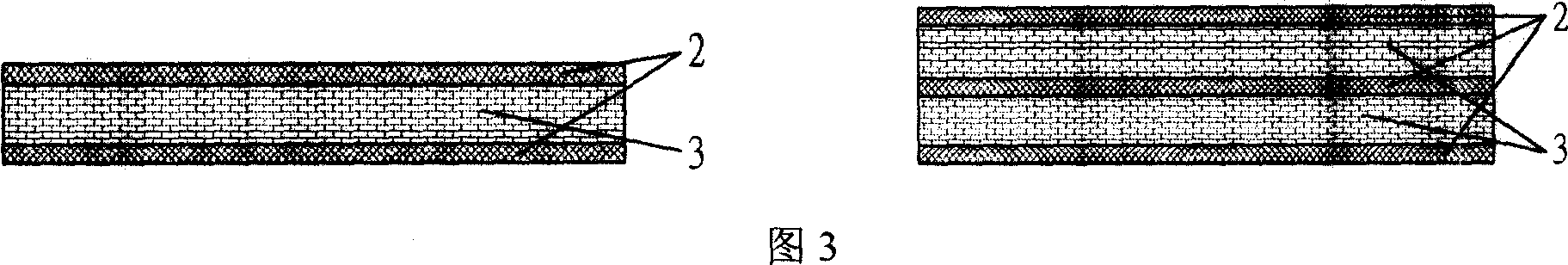

[0036] The resulting composite material is shown in Figure 3:

[0037] 2 in Fig. 3 is a fiber layer, 3 is a ceramic layer, and a similar layered structure can be a single layer or can be formed by stacking multiple layers. The thickness of the ceramic layer is 1-20 mm, and the fiber layer can be a single layer or can be formed by stacking multiple layers of fibers. The ceramic layer can be a complete plate or welded by multiple ceramic plates, and the fiber layer can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com