Bullet-proof glass

A technology of bullet-proof glass and glass, which is applied in the direction of glass/slag layered products, defenses, layered products, etc. It can solve the problems of high proportion, complex overall structure and difficult production of bullet-proof glass products, and achieve light weight and bullet-proof Good effect and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Raw material pretreatment

[0029] Clean and dry the toughened glass raw materials; PC boards are also dried for use;

[0030] 2) Composite

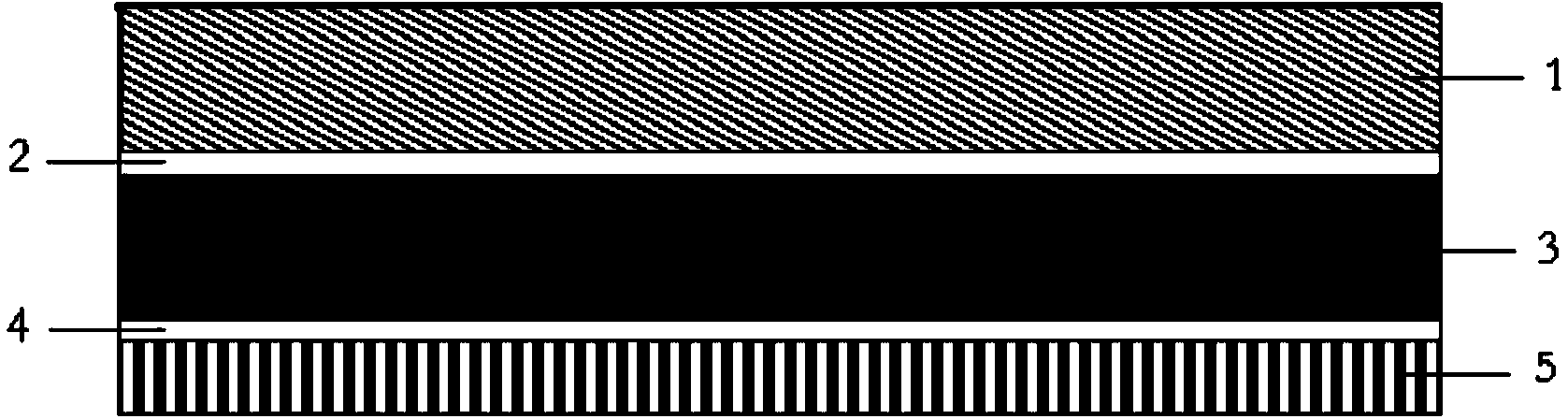

[0031] Combine 5mm tempered glass 1, 0.76mm PVB film 2, 5mm tempered glass 3, 1.89mm polyurethane film 4, and 2mm PC board 5 in sequence;

[0032] 3) Preload

[0033] First, preheat the laminated composite material until the surface temperature of the glass is 30°C, and perform the first pre-compression with a pressure of 0.3Mpa; then, raise the temperature to 70°C, and perform the second pre-compression with a pressure of 0.4Mpa;

[0034] 4) High pressure forming

[0035] The composite material after the second pre-compression is sent into the autoclave, and the temperature is raised to 130°C, the pressure is 1.3Mpa, and the heat preservation and pressure are maintained for 70 minutes. structured as figure 1 shown.

[0036] The obtained bulletproof glass is tested: the thickness is 14mm, the light transmittance is 84.6%,...

Embodiment 2

[0038] Bulletproof glass was prepared according to the method of Example 1.

[0039] Among them, in step 2), the raw materials of the combined sheet are tempered glass 5mm, PVB film 0.76mm, tempered glass 8mm, polyurethane film 1.89mm, and PC board 2mm;

[0040] In step 3), the preheating temperature is 20°C; the first precompression pressure is 0.6Mpa; the temperature is raised to 60°C again, and the second precompression pressure is 0.6Mpa;

[0041] In step 4), increase the temperature and pressure to a temperature of 120°C, a pressure of 1.3Mpa, and hold the temperature for 100 minutes;

[0042] The thickness of the obtained bullet-proof glass is 17mm after testing, its light transmittance is 82%, and the bullet-proof level can reach the F64-H level of the national standard GB17840-1999.

Embodiment 3

[0044] Bulletproof glass was prepared according to the method of Example 1.

[0045] Among them, in step 2), the raw materials of the combined sheet are float glass 4mm, PVB film 0.76mm, tempered glass 8mm, polyurethane film 1.89mm, and PC board 1mm;

[0046] In step 3), the preheating temperature is 40°C; the first precompression pressure is 0.1Mpa; the temperature is raised to 80°C again, and the second precompression pressure is 0.2Mpa;

[0047] In step 4), increase the temperature and pressure to a temperature of 140°C, a pressure of 1.3Mpa, and hold the temperature for 30 minutes;

[0048] The obtained bulletproof glass has a thickness of 15.05mm after testing, and its light transmittance is 83.7%. The bulletproof level can reach the F64-H level of the national standard GB 17840-1999.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com