Liquid-phase sintered boron carbide bulletproof material and preparation method thereof

A technology of liquid phase sintering and boron carbide, which is applied in the field of liquid phase sintering boron carbide bulletproof materials and its preparation, can solve the problems of low service life, complex process, large heat loss, etc., and achieve cost reduction and follow-up processing costs and increase Dimensional accuracy and the effect of improving ballistic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

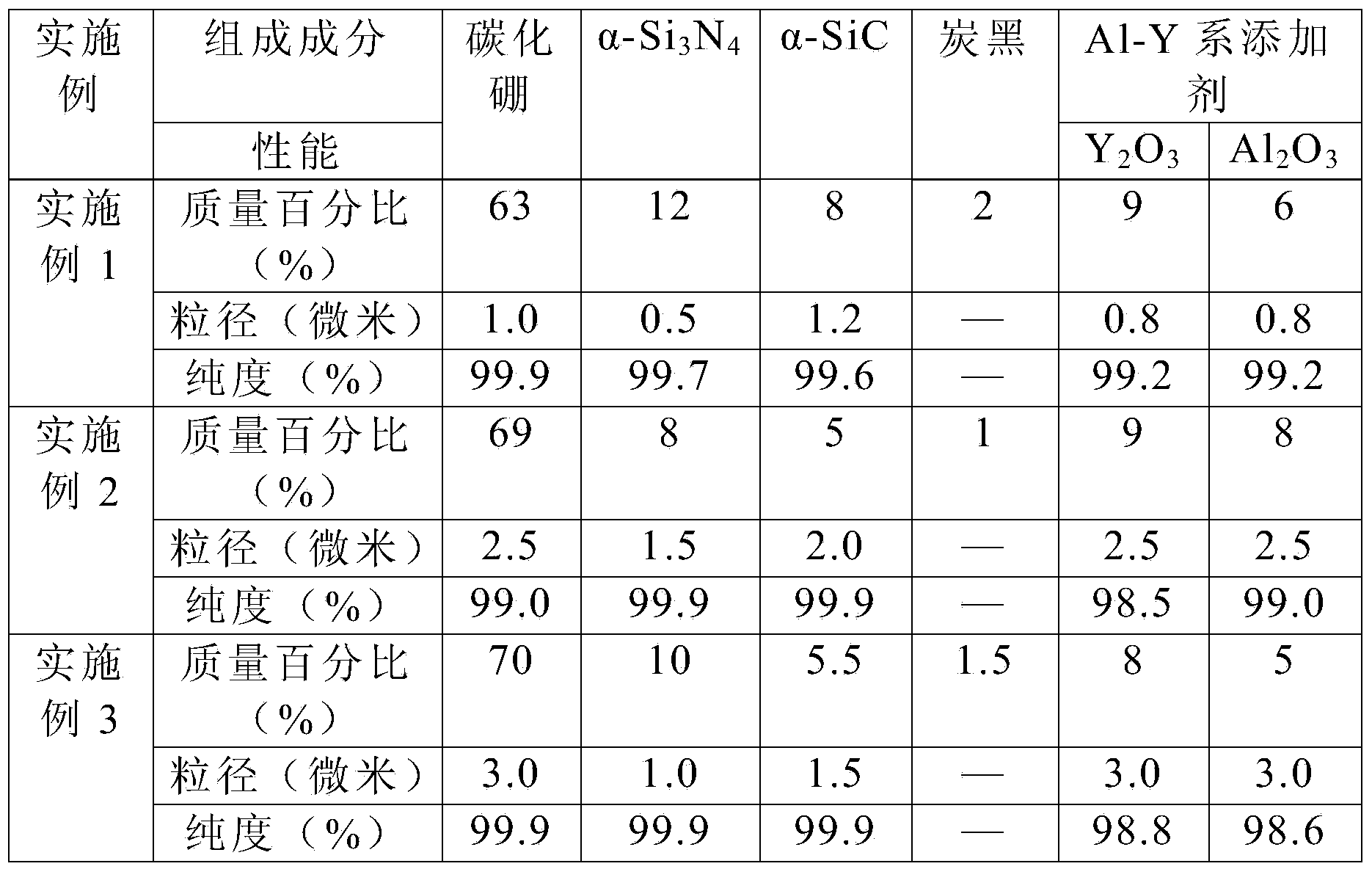

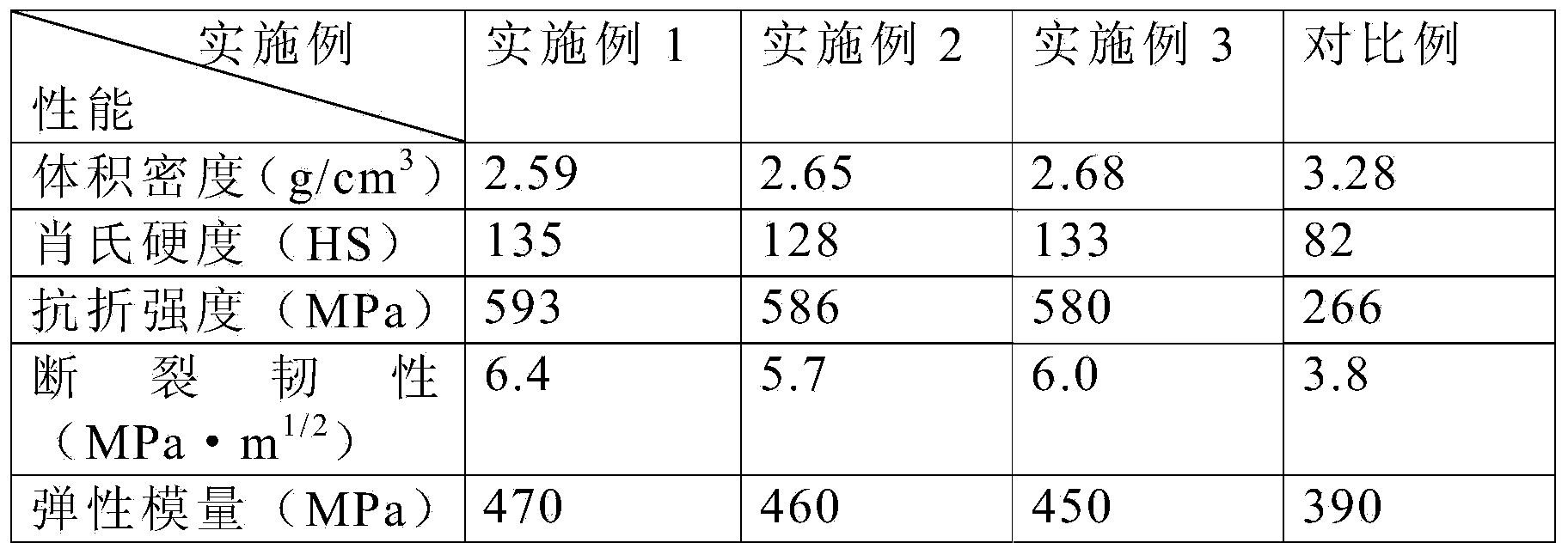

[0032] Weigh the liquid-phase sintered boron carbide bulletproof material composition and its mass percentage described in Table 1 Example 1, and the weighed boron carbide, α-Si 3 N 4 , α-SiC and carbon black are put into a ball mill, wet-milled with deionized water as a medium, and a binder phenolic resin that accounts for 10% of the mass of the slurry is added. After 4 hours, the ball-milled slurry is passed through a 120-mesh screen. ;

[0033] The sieved slurry is sprayed and granulated through a spray granulation tower. During spray granulation, the inlet temperature of the granulation tower is 200 °C, the outlet temperature is 100 °C, the speed of the feeding pump is 80r / min, and the speed of the atomizing disc is 14000r. / min, pass the granulated slurry through a 60-mesh sieve for later use;

[0034] The above-mentioned granulated slurry is loaded into the mold cavity, and is formed by dry pressing under the pressure of 50MPa, and the pressure holding time is 15s to p...

Embodiment 2

[0037] Weigh the liquid phase sintered boron carbide bulletproof material composition and its mass percentage described in Example 2 of Table 1, and the weighed boron carbide, α-Si 3 N 4 , α-SiC and carbon black are put into a ball mill, wet-milled with deionized water as a medium, and a binder phenolic resin that accounts for 5% of the mass of the slurry is added. After 2 hours, the ball-milled slurry is passed through a 120-mesh screen. ;

[0038] The sieved slurry is sprayed and granulated through a spray granulation tower. During spray granulation, the inlet temperature of the granulation tower is 170 °C, the outlet temperature is 75 °C, the speed of the feeding pump is 35r / min, and the speed of the atomizing disc is 14000r. / min, pass the granulated slurry through a 60-mesh sieve for later use;

[0039] The above-mentioned granulated slurry is loaded into the mold cavity, and is formed by dry pressing under the pressure of 35MPa, and the pressure holding time is 5s to p...

Embodiment 3

[0042] Weigh the liquid phase sintered boron carbide bulletproof material composition and its mass percentage described in Table 1 Example 3, and the weighed boron carbide, α-Si 3 N 4 , α-SiC and carbon black are put into a ball mill, wet-milled with deionized water as a medium, and a binder phenolic resin that accounts for 14% of the slurry mass is added. After 6 hours, the ball-milled slurry is passed through a 120-mesh screen. ;

[0043] The sieved slurry is sprayed and granulated through a spray granulation tower. During spray granulation, the inlet temperature of the granulation tower is 240 °C, the outlet temperature is 120 °C, the speed of the feeding pump is 100r / min, and the speed of the atomizing disc is 14000r. / min, pass the granulated slurry through a 60-mesh sieve for later use;

[0044] The above-mentioned granulated slurry is loaded into the mold cavity, and is formed by dry pressing under the pressure of 100MPa, and the pressure holding time is 20s to prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com