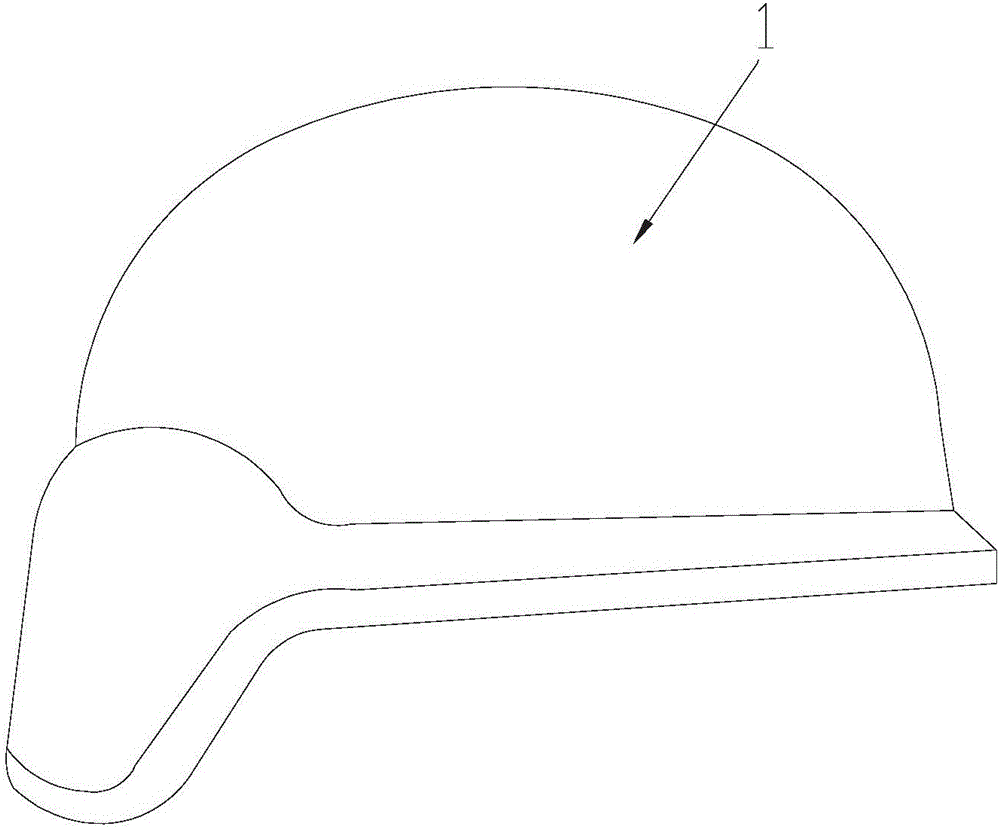

Bullet proof helmet and preparation method thereof

A technology of bulletproof helmets and thermoplastic polymers, applied in protective equipment, offensive equipment, personnel protection equipment, etc., can solve problems such as easy sticking and detachment, complicated manufacturing process, and high quality, so as to improve production efficiency, enhance resistance, Good bulletproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The material of the bulletproof helmet 1 is a mixture of carbon fiber and nylon 66 composite material, and the mass fraction ratio of carbon fiber and nylon 66 polymer material is 1:3.

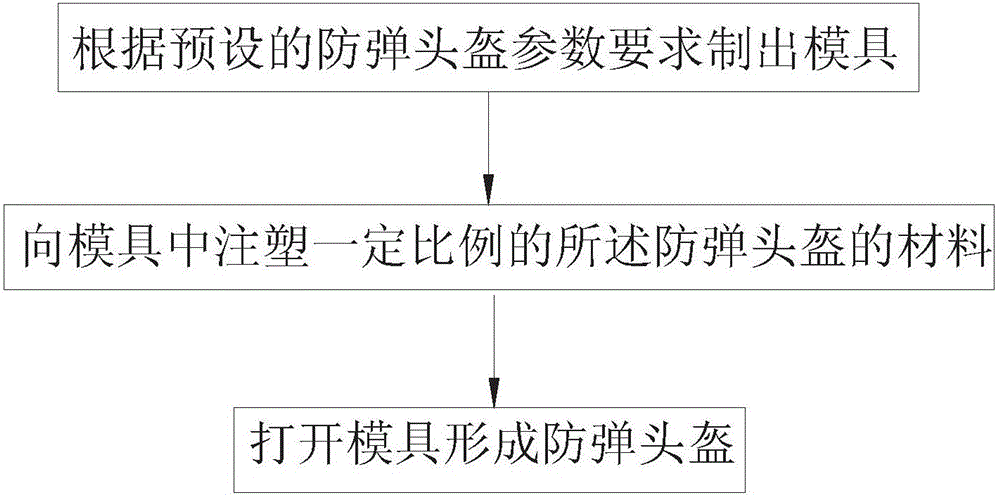

[0026] The preparation method of the bulletproof helmet 1 is as follows: the injection temperature is 270 degrees, the pressure is 120 MPa, the injection time into the mold is 15 seconds, the pressure holding time is 5 seconds, and the protective area of the helmet is 0.13m 2 , the thickness of the protective material is 8mm, and the mass of the bulletproof helmet made is 1.32kg. The protection level conforms to the latest standard of the public safety industry of the People's Republic of China GA 293-2001 "Police Bulletproof Helmet and Mask" Class III standard.

Embodiment 2

[0028] The bulletproof helmet 1 is made of aramid fiber mixed with nylon 66 composite material, and the mass fraction ratio of aramid fiber to nylon 66 polymer material is 1:3.

[0029] The preparation method of the bulletproof helmet 1 is as follows: the injection temperature is 270 degrees, the pressure is 150 MPa, the injection time into the mold is 18 seconds, the pressure holding time is 6 seconds, and the protective area of the helmet is 0.13m 2 , The thickness of the protective material of the helmet is 7.5mm, and the mass of the bulletproof helmet made is 1.31kg. The test results meet the latest standard of the public safety industry of the People's Republic of China GA293-2001 "Police Bulletproof Helmet and Mask" Class III standard.

Embodiment 3

[0031] The material of the bulletproof helmet 1 is a mixture of aramid fiber and nylon 66 composite material, and the mass fraction ratio of aramid fiber and nylon 66 polymer material is 1:4.

[0032] The preparation method of the bulletproof helmet 1 is as follows: the injection temperature is 270 degrees, the pressure is 150 MPa, the injection time into the mold is 18 seconds, the pressure holding time is 6 seconds, and the protective area of the helmet is 0.13m 2 , the thickness of the protective material of the helmet is 8.1mm, and the mass of the bulletproof helmet made is 1.61kg. The test results meet the latest standard of the public safety industry of the People's Republic of China GA 293-2001 "Police Bulletproof Helmets and Masks" Class III standard.

[0033] The invention has the beneficial effects of adopting an integral injection molding method, using thermoplastic polymer materials and reinforcing fiber materials and mixing them in reasonable proportions, improvi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com