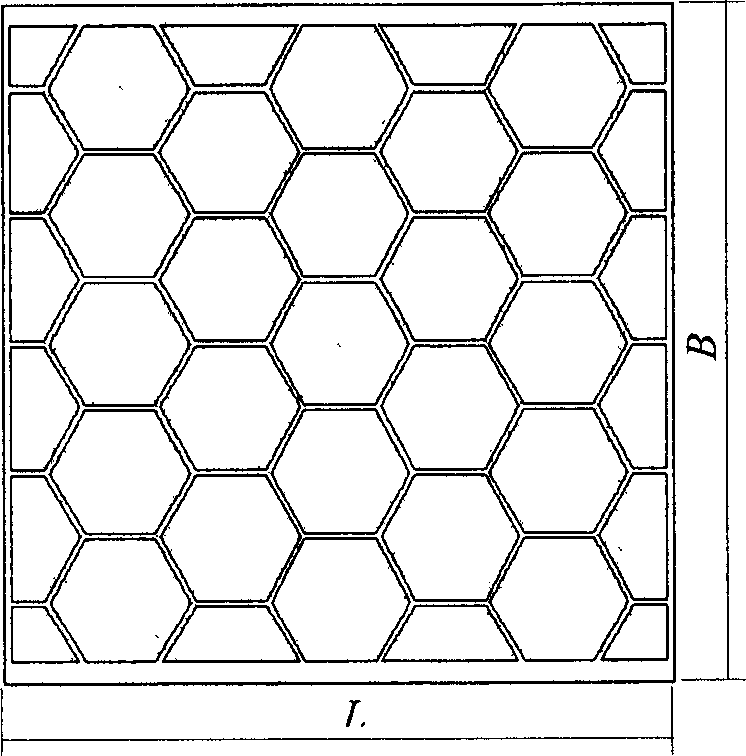

Composite bulletproof armour with steel honeycomb ceramic sandwich and manufacture thereof

A technology of honeycomb ceramics and bulletproof equipment, which is applied to the structure of armor plates, chemical instruments and methods, lamination devices, etc., and can solve the problems of complex physical process of striking, low interface bonding strength, and impact on bulletproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

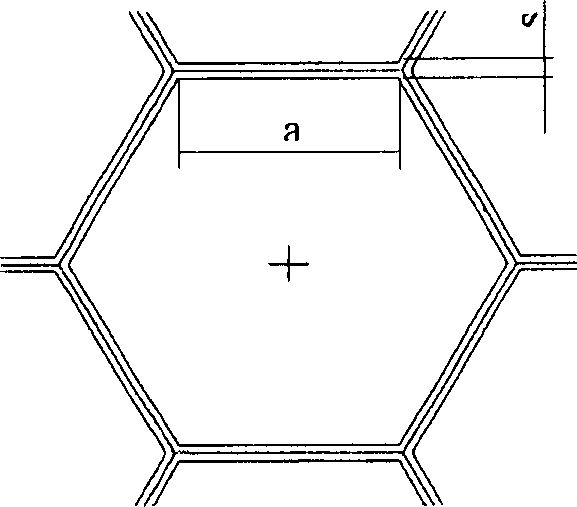

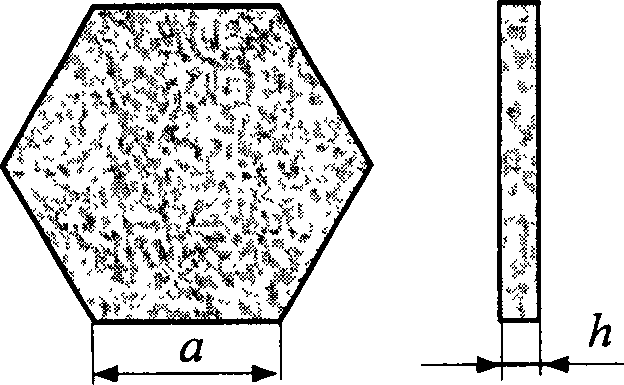

[0017] First prepare the materials, the required materials include: processed by brazing or wire cutting figure 1 The honeycomb core plate (3) shown; processing image 3 As shown in the ceramic chip (4), the ceramic chip can be made into a flat shape or a curved shape, and its size should match the size of the honeycomb holes on the honeycomb core board; the metal face plate (1) and the metal back plate (6) Bulletproof steel plates that have been heat-treated after cold rolling should be used; Ag72Cu metal brazing filler metals and epoxy resin-based high-strength structural adhesives used for interface connections.

[0018] followed by assembly and welding, the structure is as Figure 4 and Figure 5 As shown, the specific process is: the Ag72Cu metal brazing material is sandwiched between the metal back plate (6) and the honeycomb core plate (3), placed in a vacuum furnace, and heated at 1×10 -2 Under Pa vacuum, heat to 845°C, keep warm for 45 minutes for brazing, take out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com