Method for preparing bulletproof formed part

A molding and pre-press molding technology, applied in protective equipment, chemical instruments and methods, offensive equipment, etc., can solve the problems of reducing the bulletproof performance of bulletproof moldings and increasing bulletproof pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

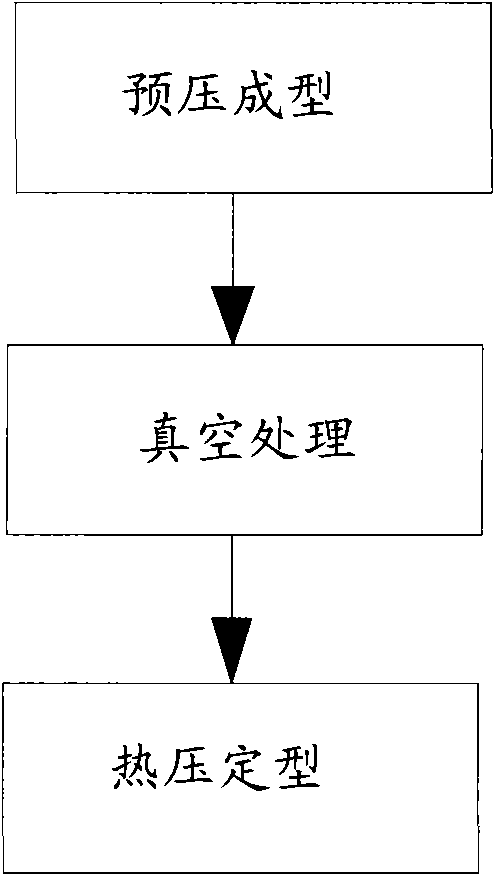

[0027] see figure 1 , is the flow chart of the process for preparing bulletproof molded parts of the present invention. Will have count be 200, the Dyneema SK75 (intensity is 35cN / dtex, modulus is 1100cN / dtex) fiber that Holland DSM company produces is parallel-oriented on the plane, the KRATON G-1650 that kraton company produces is according to weight ratio 22 % Dissolved in No. 120 solvent oil (2,3-butanedione) as an adhesive and compounded with fibers to make a surface density of 40g / m 2 The weight of the fiber in the single-layer non-woven fabric is 32g.

[0028] Take 65 layers of the above-mentioned single-layer non-woven fabrics to be superimposed on each other, and the fibers in the adjacent non-woven fabrics are arranged at 0° / 90°, and a pressure of 0.3MPa is applied to the lamination of the non-weft fabrics so that the air between the layers is selected. After heating up to 115°C, a pressure of 2.5MPa is applied for pre-compression molding.

[0029] Put the pre-pre...

Embodiment 2

[0032] With a count of 200, the fibers of Dyneema SK75 produced by DSM Company are oriented in parallel on the plane, and KRATON D-1107 produced by Kraton Company is dissolved in No. 120 solvent oil according to the weight ratio of 18% as an adhesive after compounding with the fiber The surface density is 38g / m 2 The weight of the fiber in the single-layer non-woven fabric is 31.5g.

[0033] Take 66 layers of the above-mentioned single-layer non-woven fabrics to be superimposed on each other, and the fibers in the adjacent non-woven fabrics are arranged at 0° / 90°, and a pressure of 0.4MPa is applied to the lamination of the non-weft fabrics to escape the air between the layers. Then heat up to 115°C and apply a pressure of 2.5 MPa for pre-compression molding.

[0034] Place the pre-pressed non-weft cloth lamination in a vacuum oven at a temperature of 128°C for 60 minutes to keep warm for 60 minutes. The vacuum degree of the vacuum oven is 0.18kpa. After heat preservation, co...

Embodiment 3

[0037] Will have count be 200, the Dyneema 76 (intensity is 37cN / tex, modulus is 1200cN / tex) fiber that Holland DSM company produces is parallel-oriented on the plane, the KRATON G-1650 that kraton company produces is according to weight ratio 22 % Dissolved in No. 120 solvent oil (2,3-butanedione) as an adhesive and compounded with fibers to make a surface density of 39.6g / m 2 The weight of the fiber in the single-layer non-woven fabric is 31.6g.

[0038] Take 64 layers of the above-mentioned single-layer non-woven fabrics to be superimposed on each other, and the fibers in the adjacent non-woven fabrics are arranged at 0° / 90°, and a pressure of 0.3MPa is applied to the lamination of the non-woven fabrics to make the air between the layers escape. After heating up to 115°C, a pressure of 2.5MPa is applied for pre-compression molding.

[0039] Put the pre-pressed non-weft cloth lamination in a vacuum oven at a temperature of 125°C for 60 minutes. The vacuum degree of the vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com