A kind of preparation technology of high refractory fused silica

A technology of fused silica and preparation technology, which is applied in the field of preparation technology of high refractory fused silica, can solve the problems such as unresolved crystallization of fused silica, achieve avoiding chemical stability, improve plasticity, and make the preparation process simple and efficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

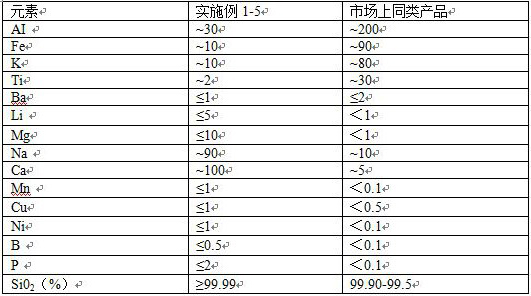

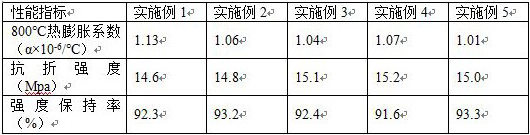

Embodiment 1

[0045] (1) Preparation of high-purity fused silica: the vein quartz raw ore is first graded and washed to remove clay, and then crushed to a particle size range of 4-25mm, and the crushed quartz particles are acid-treated to obtain high-purity quartz raw materials; for high-purity quartz The raw materials are melted to obtain fused silica bulk materials; the fused silica bulk materials are manually crushed and sorted to remove obvious impurities, and then crushed by a centrifugal crusher to the required particle size range of 1-10 mm; the crushed fused silica Quartz powder is processed by magnetic separation to obtain high-purity fused silica powder;

[0046] (2) Ingredients: the high refractory fused silica mainly includes the following components in parts by mass: 50 parts of high-purity fused silica powder, 45 parts of binder, 22 parts of cordierite, and 13 parts of sillimanite; The particle gradation ratio of the high-purity fused silica powder is 20-30 mesh: 30-60 mesh: 6...

Embodiment 2

[0064] (1) Preparation of high-purity fused silica: the vein quartz raw ore is first graded and washed to remove clay, and then crushed to a particle size range of 4-25mm, and the crushed quartz particles are acid-treated to obtain high-purity quartz raw materials; for high-purity quartz The raw materials are melted to obtain fused silica bulk materials; the fused silica bulk materials are manually crushed and sorted to remove obvious impurities, and then crushed by a centrifugal crusher to the required particle size range of 1-10 mm; the crushed fused silica Quartz powder is processed by magnetic separation to obtain high-purity fused silica powder;

[0065] (2) Ingredients: The high refractory fused silica mainly includes the following components in parts by mass: 55 parts of high-purity fused silica powder, 40 parts of binder, 20 parts of cordierite, and 10 parts of sillimanite; The particle gradation ratio of the high-purity fused silica powder is 20-30 mesh: 30-60 mesh: 6...

Embodiment 3

[0083] (1) Preparation of high-purity fused silica: the vein quartz raw ore is first graded and washed to remove clay, and then crushed to a particle size range of 4-25mm, and the crushed quartz particles are acid-treated to obtain high-purity quartz raw materials; for high-purity quartz The raw materials are melted to obtain fused silica bulk materials; the fused silica bulk materials are manually crushed and sorted to remove obvious impurities, and then crushed by a centrifugal crusher to the required particle size range of 1-10 mm; the crushed fused silica Quartz powder is processed by magnetic separation to obtain high-purity fused silica powder;

[0084] (2) Ingredients: The high refractory fused silica mainly includes the following components in parts by mass: 53 parts of high-purity fused silica powder, 40 parts of binder, 25 parts of cordierite, and 15 parts of sillimanite; The particle gradation ratio of the high-purity fused silica powder is 20-30 mesh: 30-60 mesh: 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com